1 襯墊的形狀和尺寸設計標準 印刷電路板設計

這個 印刷電路板標準封裝 應調用庫.

所有焊盤的最小單側不小於0.25毫米, 整個襯墊的最大直徑不超過組件孔徑的3倍.

儘量確保兩個襯墊邊緣之間的距離大於0.4毫米.

在密集佈線的情况下, 建議使用橢圓形和長方形連接板. 單面板墊的直徑或最小寬度為1.6mm; 雙面板弱電線路板只需加0.孔徑5mm. 焊盤過大很容易導致不必要的連續焊接.

孔徑超過1的襯墊.2mm或襯墊直徑超過3.0mm should be designed as diamond or quincunx pads

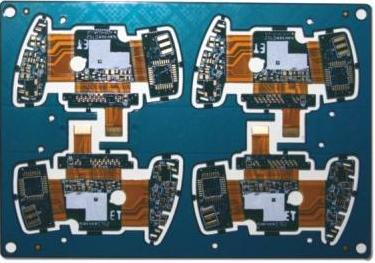

For plug-in components, 為了避免焊接過程中銅箔破裂的現象, and the single-sided connecting plate should be completely covered with copper foil; the minimum requirement for double-sided panels should be filled with teardrops; as shown in the figure:

All machine insert parts need to be designed as drip pads along the bent leg direction to ensure full solder joints at the bent leg.

大面積銅皮上的墊子應為菊花形墊子, 不焊接. 如果地面和電源線面積較大 印刷電路板 ((面積超過500平方毫米)), the window should be partially opened or designed as a grid fill (FILL).

第二, 印刷電路板製造 process requirements for pads

Test points should be added to the two ends of the chip components that are not connected to the plug-in components. 測試點的直徑等於或大於1.8mm,便於線上測試儀測試.

如果具有密集引脚間距的IC引脚墊未連接到手動插頭墊, 需要添加測試墊. 用於貼片集成電路, 測試點不能放置在SMD IC絲網中. 測試點的直徑等於或大於1.8mm,便於線上測試儀測試.

如果焊盤間距小於0.4毫米, 當超過波峰時,必須使用白油以减少連續焊接.

貼片元件的兩端和末端應設計為鉛錫. 鉛錫寬度建議使用0.5mm電線, 長度一般為2或3mm.

如果單面板上有手工焊接部件, 應移除錫槽, 方向與焊接方向相反, 孔的寬度為0.3MM至1.0MM; (50-70% of the hole diameter) as shown below:

這個 spacing and size of the conductive rubber buttons should be consistent with the actual size of the conductive rubber buttons. The 印刷電路板板 connected to this should be designed as a gold finger, 並應規定相應的鍍金厚度.

The size and spacing of the pad should be the same as the size of the chip component (1:1).

For the solder joints with the distance between the pads on the same straight line (the number of pads greater than 4) is less than 0.4毫米, 在加入白油的基礎上, 組件的長邊盡可能平行於波峰方向, 然後,在末端的焊盤上添加一個空焊盤或放大末端的焊盤, 從而吃掉尾部焊料,减少連續焊接.