![]()

*產品通過權威認證和品質管制體系。*生產前通過工程設計進行預防和控制。*嚴格的生產過程控制。*完善的產品品質體系。*測試包括AOI和電力100%測試。*高壓/阻抗/微截面/可焊性

熱衝擊/可靠性/絕緣電阻測試等。

品質方針:以質量為主要檢查點,從細節出發,製造出高品質的產品,為客戶提供滿意的產品和服務。

品質目標:-準時交貨率:100%-生產完美率:98%-成品檢驗率:99%

服務目標:-客戶滿意度:99.9%-客戶投訴/退貨率:0.5%/0.5%-客戶投訴處理-行動時間:1小時內,處理時間:4小時內

檔案審查:對客戶資訊進行詳細的工程檢查,解决

及時發現問題並提出合理化建議。

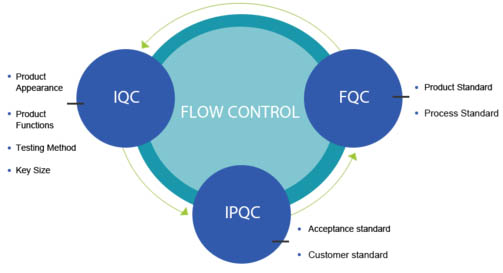

產品檢驗:-進料檢驗-合格入庫,不合格退貨-工裝夾具測試-送相關部門合格,拒收退貨-生產過程檢驗-每道工序的產品在出廠前均合格

進入下一道工序,新增巡檢控制

驗收標準:IPC-A-600G標準(PCB AQL)

-IPC-6018A(高頻PCB驗收標準)