PCB circuit board repair experience sharing, circuit board is the most common object in electrical appliances, and all electrical appliances play an important role, because the machine mainly depends on it to work, so damage means that the entire machine is not in working condition.

Regarding the broken machine, I believe that most beginners will dare not disassemble the machine for maintenance because they don't understand it well. For this, it is recommended that everyone boldly disassemble the shell to observe the circuit first, and then do it,

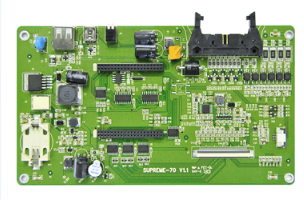

provided that you have to be careful! Most of the machine is divided into several circuit boards to work, like the power board, the mains is passed through the corresponding components Convert 220V mains power to the voltage required by each section to supply the corresponding sections. The main board is equivalent to the control center of the machine, the brain of the machine, responsible for the interactive data transmission between the machine and the human, and the corresponding work of controlling other sub-modules, so as to realize the machine Complete each action! But to complete this kind of work, each circuit board needs to be in a normal working state, and if it is damaged, as mentioned at the beginning of the article, the machine will strike!

Although the functions of the various plates in the machine are different, they are basically a board with a collection of components, and the maintenance methods are roughly the same. So, let me tell you about some methods and skills of my circuit board repair, and give you a reference for beginners!

PCB repair is divided into disconnection test and online test. The disconnection test is to disconnect the power supply test board. The resistance to ground of the major power supply inlets on the board is correct. If the resistance of which group is low or directly short-circuited, then It means that there is a partial short circuit on the circuit board, or the component is broken or the chip is damaged. Basically, the short circuit is faulty. It is necessary to eliminate the fault point and continue to find out the specific situation!

There is also online measurement (online measurement and oscilloscope measurement, because after the online test and disconnection resistance measurement with a multimeter, you can basically determine where the fault is, so I won’t introduce it). After the short-circuit test, rule out that there is no short circuit on the circuit board. After powering up, test the voltage of each group is not normal! For example, if some lines are disconnected, there will be faults if the power supply is not passed. It is necessary to make better components. Power arrives at the designated position! Circuit board repair is mainly to be familiar with the repaired PCB design. You must know which part of the board is the central control area, which part is the cache area, which part is the clock and reset, and many boards are similar. As long as you pay more attention, pay more attention to carefully analyze the overall circuit, and sort out the corresponding areas on the board, you will be able to repair it yourself!