iPCB is a reliable full turnkey PCB assembly service solution for prototype quantities, small-volume to mid-volume production runs, and a one-stop PCB manufacturing and turnkey PCB assembly company. In addition, as a provider of one-stop PCB assembly services, our firm provides expert consulting in Design for Manufacturing (DFM).

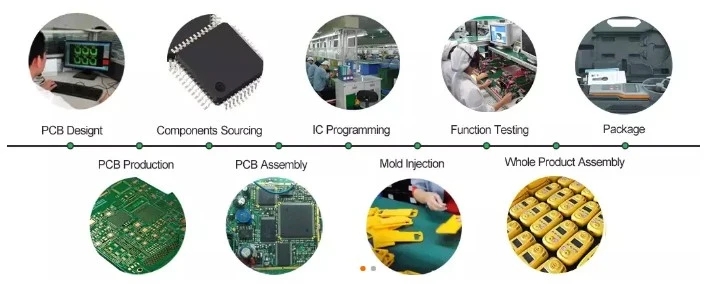

We have been in this line for more than 15 years. With the professional R&D team and skillful workers, we can put your design into a physical product and also put your idea into a workable strategy and development. We can offer you the one-stop solution from PCB, Components purchasing, Components assembly, test to the whole fabrication.

Advantages of turnkey PCB assembly

1) Strict product liability, taking IPC-A-160 standard

2) Engineering pretreatment before production

3) Production process control (5ms)

4) 100% E-test, 100% visual inspection, including IQC, IPQC, FQC, OQC

5) 100% AOI inspection, including X-ray, 3D microscope, and ICT

6) High-voltage test, impedance control test

7) Micro section, soldering capacity, thermal stress test, shocking test

8) In-house PCB production

9) No minimum order quantity and free sample

10) Focus on low to medium volume production

11) Quick and on-time delivery

pcb assembly Quality Control

Our company executes the ROHS requirements, all the products we provide to our customers will follow ROHS standards.

Turnkey PCB ERP quality system

Making all departments, like production, supply, sales, inventory, human resources, finance, logistics, decision-making departments, can share resources information in an enterprise. So that enterprises could analyze, forecast, making decisions for all related enterprise management activities. Under this management system, the whole enterprise business process will be controlled and improved under a healthy situation.

An electrostatic assembly protection method

It inhibits static charge accumulation and static charge generation.

We are eliminating actual static charges quickly and safely.

The implementing electrostatic protection area(EPA) and sound grounding system.

Turnkey PCB service Packaging & shipping

Bubble Anti-static Bag. For AL, Composite Anti-static Bag, Double Flute Carton, Inner Pads(Top and Bottom), Inner Cards, Pallet and Pallet Wrapper.

Testing Procedures For SMT DIP assembly service

We perform multiple quality assuring procedures before shipping out any PCB board. These include:

* Visual Inspection

* Flying probe, fixture tool

* Impedance control

* Solder-ability detection

* Digital metallographic microscope

* AOI (Automated Optical Inspection)

Where is the application for our turnkey pcb assembly?

Our Turnkey PCB board assemblies are widely used in Industrial and Energy, Medical and Healthcare, Automotive, Information and Communication Technology, Wearables, consumer electronics.

Our PCB board manufacture and Turnkey PCB assembly service

1. No MOQ for Printed circuit board and PCBA

2. One-stop solution for various OEM electronic PCB assembly.

3. Professional PCB Board engineer for one-to-one service.

3. 100% PCBA AOI tested guarantee before shipping

4. RoHS, UL, ISO, SGS certificate approved

5. Factory production Capability of 30000 sqm/month

6. Turnkey EMS (electronics manufacturing service) including PCB manufacturing, components sourcing, PCB assembly, PCBA conformal coating, box build, PCBA function testing.

7. Excellent Customer Service to Meet Your Special Needs

8. Shipment on time.

PCBs We Can Make

1. Rigid PCBs, Flex PCBs, and Rigid-Flex PCBs

2. Aluminum Backed PCBs and Metal Core PCBs

3. Advanced PCBs. such as DHIPCBs, Hight TG PCBs, High-Frequency PCB, Carbon Ink PCB, Special Material PCB, Thick Copper PCB

Turnkey PCB Assembly Technical requirement

1. Professional Surface-mounting and Through-hole soldering Technology.

2. Various sizes like 1206,0805,0603 components SMT technology.

3. ICT(In-Circuit Test), FCT(Functional Circuit Test) technology.

4. Turnkey PCB Assembly With UL, CE, FCC, Rohs Approval.

5. Nitrogen gas reflow soldering technology for SMT.

6. High Standard SMT&Solder Assembly Line.

7. High density interconnected board placement technology capacity.

What we need

1. Gerber files of the bare PCB.

2. Bill of materials to include: Manufacturer's part number, type of part, type of packaging, component locations listed by reference designators, and quantity.

3. Dimensional specifications for non-standard components.

4. Assembly drawing, including any change notices.

5. Final test procedures (if available).

Our advantages Turnkey PCB assembly service

1. High-end, Small volume, and Various kinds of PCBA service offered.

2. Speedy, Flexible, and one-stop service in PCBA.

3. Assembly and Purchasing service offered, all components are promised to be purchased 100%, from Original factories or their pointed agents.

4. Transparent quotation, cost, and benefit are detailedly opened to customers.

5. With professional Engineers and Long-term successful experience in cooperating with customers inland and overseas, all new projects can be developed faster and better than expected.

6. With USA or Japan imported tin cream and tin bar, and 100% AOI testing during production, all PCBAs we made are more reliable.

iPCB is a reliable, complete turnkey PCB assembly service solution for prototype quantities and small-volume to mid-volume production runs, and a one-stop PCB manufacturing and Turnkey PCB assembly company. Please send your customized requirements with the design files; all information is secure and confidential. E-mail: sales@ipcb.com