What is a PCB?It is the abbreviation of the printed circuit board.In some countries, it also called printed wiring board.PCB comprises insulated baseboards, copper foil connecting wires, and bonding pads for electronic welding components. It has the dual function of a conductive line and an insulating substrate, which can replace complex wiring and realize circuit connections between components in a circuit.

It is the motherboard of electronic components.Before the emergence of printed circuit board, electronic components, directly connected with wires, and wiring was often messy and prone to error. Nowadays, after the use of printed wiring board for electronic equipment, you can avoid the error of manual wiring, electronic components can be automatically DIP or SMT, automatic welding, automatic testing, to ensure the quality of electronic equipment, improve productivity, reduce costs, and easy maintenance.

Printed Circuit Board

What is PCB made of? The earliest used was paper-based copper foil. Since the advent of semiconductor transistors in the 1950s, demand for it has risen dramatically. In particular, the rapid development and wide application of integrated circuits, so that the volume of electronic equipment is getting smaller and smaller, the density and difficulty of circuit wiring is also getting bigger and bigger, which requires continuous updating of electronic boards. At present, the type of the board has developed from single-sided to double-sided, multi-layer and flexible PCB, structure and quality have developed to ultra-high density, miniaturization and high reliability, new design methods and design applications, materials and manufacturing processes continue to emerge. Various computer-aided design applications have also been popularized and promoted. In professional printed circuit manufacturers, mechanized and automated production has largely replaced manual operation.

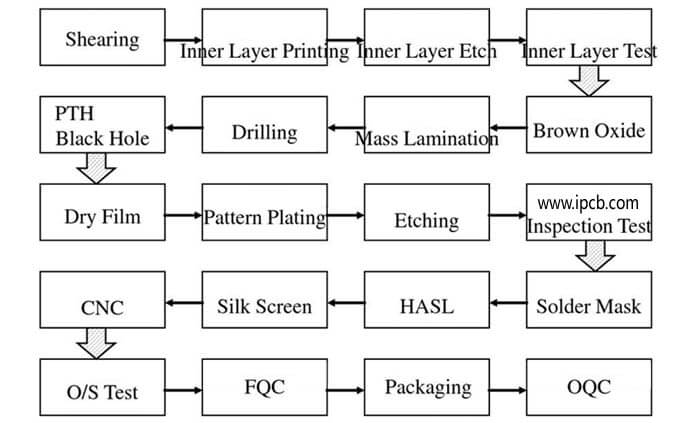

PCB manufacturing process

1. Material cutting, filleting, edge planing, cutting is the process of cutting the original PWB copper clad laminate into a work board that can be made on the production line, generally cutting into a work board of about 40*50cm.

2. VIA drilling, you need to use a CNC drill to drill through the VIA holes on the top and bottom layers of the PWB.

3. Through-hole copper sinking, after drilling the entire material wall without copper, the PCB surface needs to use the copper sinking process to drop a thin layer of copper.

4. For PWB electroplating, there is a thin copper layer on the copper impregnated PCB surface, which can not meet the requirement of 18um copper thickness at the bottom of IPC. Therefore, it needs to be electroplated to increase the consistency of the drill. The factory production standard of ipcb is 20-26um.

5. A blue dry film is applied to the laminated board after PCB lamination. The dry film is a carrier and is very important in the circuit process. Therefore, the dry film process is named after it. Compared to wet film, dry film has higher stability and better quality and can be used directly as a non-metallized through-hole.

6. For circuit exposure, first align the circuit film with the PWB with the dry film pressed and then place it on the exposure machine for exposure. The dry film is exposed to the place where there is no circuit film under the energy of the lamp tube of the exposure machine. After the PWB circuit exposure process, the areas with circuits are not exposed, and those without circuits are disclosed.

7. The circuit is etched, and the copper that needs the course is left, and the copper is etched away with sulfuric acid where there is no need for copper.

8. Make a solder mask by screen printing or coating solder mask ink, apply a layer of solder mask on the board surface to prevent short circuits during soldering, usually use green, blue, red, white, black solder mask.

9. Printed silkscreen, print the position number of the component and the silkscreen of the PWB model on the PWB, usually a white or black silkscreen.

10. PCB surface treatment, copper tends to exist in the form of oxide, It is prone to moisture oxidation when exposed to the air for a long time, and it is unlikely to remain as original copper for a long time, so surface treatment on the copper surface is required. The most basic purpose of surface treatment is to ensure good solderability or electrical properties.

11. PWB molding, punch the assembled work board PNL into SET or PCS that needs to be delivered through CNC or die, and the corresponding shape processing V Cut, chamfering, step groove, tapered hole, etc.

12. PCB test, use PWB flying probe test or general test electromechanical performance to check whether it has an open or short NG PCB board. Sometimes, a PWB impedance test and a PWB high voltage test are necessary.

13. FQC final inspection, check the appearance, size, aperture, thickness, marking of PWB, etc, to meet customer needs. Then, ship qualified PWB in vacuum packaging.

The Function of and the Characteristics of the electronic board.

1. Assemblable.The printed circuit board provides support for fixing and assembling electronic components,wiring,and electrical connection or insulation between various electronic members of a printed circuit and provides the required electrical characteristics.As a result,printed circuit products can easily standardize the assembly of multiple components and can automate and scale the batch production of electronic products.

2. High reliability and provides the basis for automatic DIP and SMT.

3. Productive. When electronic devices use printed circuit, the consistency of the printed circuit avoids errors in manual wiring.It can also realize automatic insertion or attachment of electronic components, automatic soldering, and automatic detection, ensuring the quality of electronic products,improving labor productivity,reducing costs, and facilitating maintenance.

4. Provide the required electrical, characteristic impedance, and electromagnetic compatibility for the pcb circuit in high speed PCB or high frequency PCB.

5. Productive, and the pcb circuit embedded with passive components provides certain electrical functions, simplifies the electronic installation procedure, and improves the product's reliability.

6. High density and provides an effective chip carrier for miniaturized chip packaging of electronic components in large scale and ultra large scale electronic packaging components.

Providers of commonly used PCB design software include Altium, Cadence, Mentor, etc. Altium was formerly known as Protel, and the successively introduced Protel99SE, ProtelDXP, and AltiumDesigner (AD) are widely used. Other commonly used software includes pads, power PCB, MentorEE, allegro, CADENCE, Autocad, OrCAD, Zuken CadStart. Used for manufacturing, the software consists of Genesis2000, CAM350,C-CAM/V2000, Cits25/si6000/si8000 produced by Polar. iPCB uses PCB design software to transfer Gerber files and PWB manufacturing software for CAM processing.

PWB is widely used, including consumer electronics,automotive electronics, semiconductor packaging, network communications, medicine, aerospace, and other fields. From the perspective of PWB demand,currently driven by the rapid development of new energy vehicles, automotive electronics. The demand for PWB has grown substantially, and there is also a great demand for consumer electronics and semiconductor packaging.

PCB price calculation and quotation

The price is composed of many factors

1. The different materials used to cause different prices

Take the ordinary double sided PCB board as an example. The board materials generally include FR4, CEM3, etc. The electronic board thickness varies from 0.6mm to 3.0mm, and the copper thickness varies from ½oz to 3oz. All of these are on the board. The above has caused a huge price difference; in terms of solder mask ink, there is also a distinct price difference between ordinary thermosetting oil and photosensitive green oil, so the difference in materials has caused the price diversity.

2. The price is different due to the difference in the production process used

Different production processes will cause additional costs. For example, gold plated pcb and tin-sprayed pcb plate, the production of gongs (milling) pcb plate and beer (punching) pwb plate, and the use of silk printed circuits and dry film circuits will result in different costs, resulting in different prices.

3. PWB prices are different due to different PCB manufacturing difficulties

Even if the PWB material is the same and the process is the same, the difficulty of the PWB itself will cause different costs. For example, there are 1000 holes on two kinds of pcb circuit. The hole diameter of one panel is more significant than 0.6mm, and the hole diameter of the other plate is smaller than 0.6mm, which will result in different drilling costs. For example, the two kinds of circuit boards are the same, but the line width and line spacing Different, one type is more significant than 0.2mm. One type is less than 0.2mm, which will also cause different production costs because the complex board has a higher scrap rate, which will inevitably increase the cost and drive the price diversity.

4. Different customer requirements will also cause different prices

The level of customer requirements will directly affect the production rate of the board factory. For example, a board according to IPC-A-600E, IPC class2 requires a 98% pass rate, but IPC class3 requirements may only have a 90% pass rate,thus causing blank circuit board factories Different costs ultimately lead to volatile product prices.

5. PCB prices are different due to different manufacturers

Different printed circuit board manufacturers have different process equipment and technology levels, and even for the same product, the cost will be different. Nowadays, many manufacturers prefer to produce gold-plated PWBs because the process is simple and the cost is low. However, some manufacturers also have gold-plated PCBs, and since the scrap rate will increase, resulting in higher prices, they prefer to produce tin-sprayed PWBs, so their quotations for tin-sprayed blank PWBs are lower than those for gold-plated PCBs.

6. PCB price differences caused by different customer payment methods

At present, manufacturers generally adjust prices according to other payment methods, ranging from 5% to 10%, which also causes price differences. You can visit iPCB, a circuit board factory.

7. PCB manufacturers are located in different regions, resulting in different prices

In terms of geographic location in China, the price is increasing from south to north, and there are specific differences in prices in different regions. Therefore,other areas also cause different PCB quotations.

How to calculate PCB quotation?

1. blank circuit board costs, different electronic print board costs, and different electronic print board costs are additional. circuit board costs are additional.

1.1. circuit board material: FR-4, CEM-3, this is our standard double sided PWB and multilayer PWB plate, its price is also related to the thickness of the board and the thickness of copper and platinum in the middle of the board, and FR-I, CEM -1 These are our common materials, and the price of this material is also very different from the above double sided PCB. Multilayer circuit board.

1.2. It is the thickness of the printed circuit board. Its thickness is commonly used:0.4, 0.6, 0.8, 1.0, 1.2, 1.5, 1.6, 2.0, 2.4, 3.0, 3.4. The thickness and price of our conventional boards are not very different.

1.3. The thickness of copper and platinum will affect the price. The thickness of copper and platinum is generally divided into 18um, 2/1OZ, 35um, 1OZ, 70um, 2OZ, 105um, 3OZ, 140um, 4OZ, etc.

1.4. Circut board raw material suppliers, standard and commonly used ones are Shengyi. KB. Isola, TUC, and so on.

2. PCB manufacturing process costs and the different process requirements of circuit board lead to varying difficulties in the circuit board manufacturing process, and even the prices will vary.

2.1. It depends on the circuit on the PCB board. For example, the price will be calculated separately if the wire density is thinner than 4/4mm.

2.2. There is also a BGA on the board so the cost will increase relatively, and in some places, the BGA is another one.

2.3. It depends on what the board surface treatment process is. Our common ones are lead-tin spraying, hot air leveling, OSP, environmental protection board, pure tin spraying, tin, silver, and gold. Of course, surface technology is different. The price will be different too.

2.4. It also depends on the process standard; we commonly use the IPC2 level, but some customers require higher requirements, and the IPC3 level is required. Of course, the higher the middle, the higher the price.

3. Artificial water and electricity plus management costs. This cost depends on the cost control of each factory.

4. PCB drilling costs, the number of holes, and the aperture size affect the drilling costs.

In the future, PCB circuit board will have a high wiring density, small size, and lightweight, conducive to the miniaturization of electronic equipment. Under the environment of accelerated penetration of emerging technologies such as 5G communications, cloud computing, big data, artificial intelligence, Industry 4.0, and the Internet of Things, the PCB industry, as an elemental force connecting the ups and downs in the entire electronic manufacturing industry chain, will enter technology, New product cycle.

PCB Directory for iPCB

High-frequency printed circuit board | High-Speed printed circuit board | Multilayer printed circuit board |

HDI PCB | Rigid-Flex printed circuit board | IC Substrate |

PCB Assembly | Standard printed circuit board | Special printed circuit board |