Electronic Manufacturing Services = EMS or ECM (Electronic Contract Manufacturing). Electronic manufacturing provides PCB design and engineering, PCBA assembly, product manufacturing, and PCBA testing services for electronic components and printed circuit board(PCB). Electronic manufacturing is the process of manufacturing products using electronic technology and equipment. It mainly involves using electronic components and devices to connect, assemble, test, and debug circuits, ultimately forming various electronic products.

Electronics Manufacturer has two modes, OEM and ODM.

OEM = Original Equipment Manufacturer, OEM is simply manufacturing products for customers. ODM = Original design manufacturer, which includes designing and manufacturing products for customers.

Electronic Manufacturing

Advantages of electronics manufacturer

1. Customers generally provide product design solutions, including schematic diagrams, drawings, layouts, MCU programs, BOMs, PCB Gerbers, assembly SOPs, and other documents. We can also provide joint development services to customers, build prototypes based on product concepts, and then determine technical parameters, product structure, and development cycle to quickly advance research and mass production.

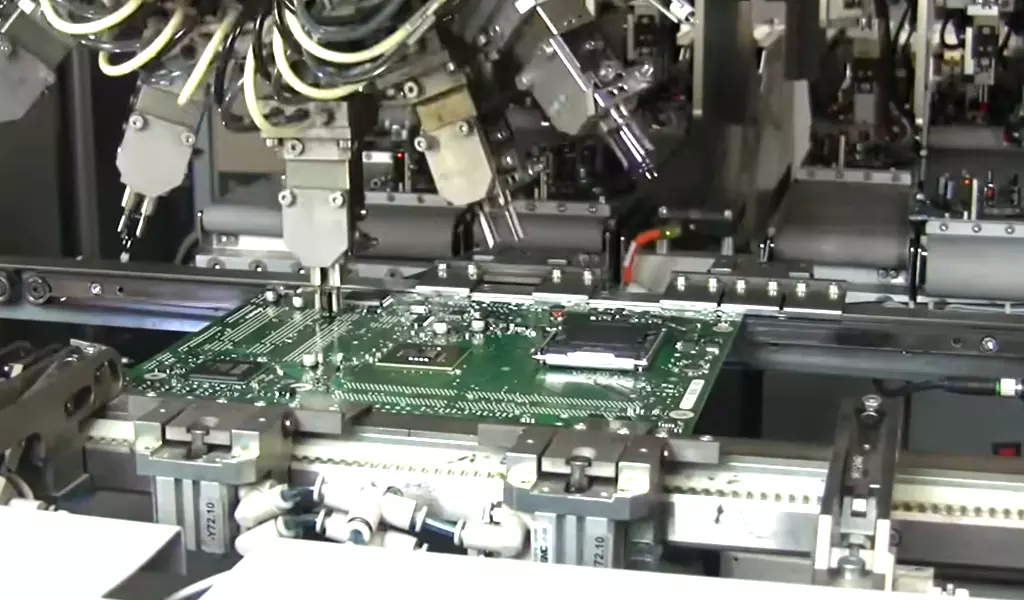

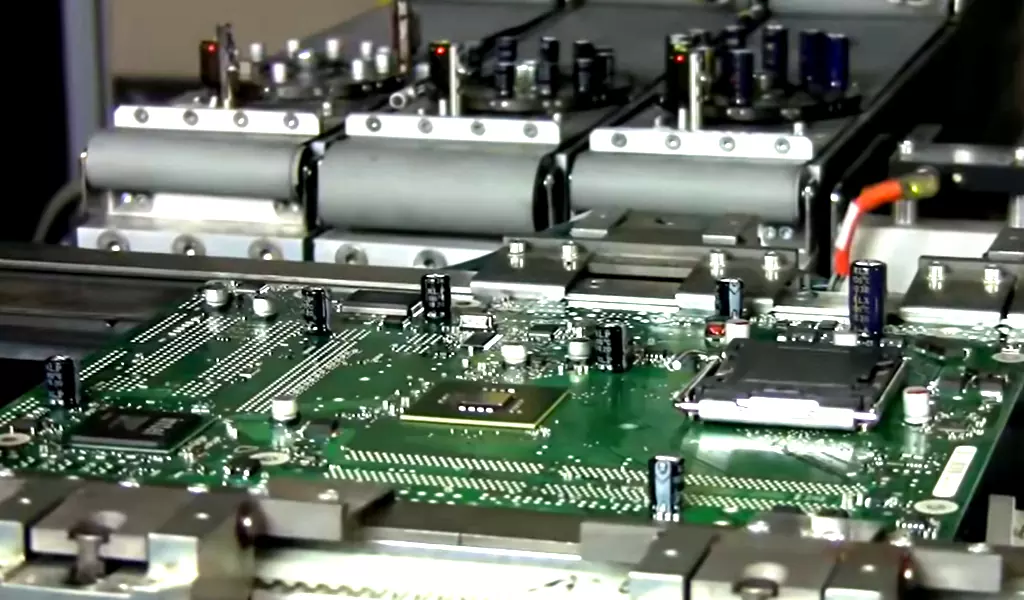

2. Quickly produce mold shells, PCB circuit boards, purchase electronic components according to the design plan, and then carry out core processes such as SMT mounting, DIP plugins, PCBA testing, three proof paint spraying, finished product assembly, aging testing, etc., in order to verify the reliability of the design and DFM manufacturability.

3. We have a mold outsourcing factory that has been cooperating for many years, equipped with more than 20 injection molding machines, complete shell injection molding, oil spraying, screen printing, transfer printing, assembly, and laser engraving process capabilities.

4. Our PCB circuit board factory produces high-quality circuit boards, including multi-layer circuit boards, impedance circuit boards, microwave high-frequency circuit boards, thick copper circuit boards, aluminum based circuit boards, copper based circuit boards, buried/blind hole circuit boards, soft hard combination circuit boards, high-precision circuit boards, etc., which are widely used in medical, security, energy, automotive, communication, industrial and other fields. IATF16949/UL/CE/RoHS/ISO9001 certification, standard flying needle testing, test stand testing, etc AOI (Automatic Optical Inspection) and other visual inspections.

5. We have a long-term and stable supply chain, establish cooperation with original manufacturers and agents of classified devices such as ICs, resistors, capacitors, inductors, connectors, crystal oscillators, display screens, transformers, relays, diodes and transistors, and obtain support in terms of payment terms and technical after-sales. Our company has established an internal SQE annual audit mechanism to evaluate all suppliers and select the best, in order to continuously ensure the supply and quality capabilities of electronic components.

6. Equipped with a professional SMT processing and manufacturing team, high-speed SMT production lines, DIP plug-in production lines, complete AOI, ICT, FCT testing process groups, and assembly processes that comply with ISO9001:2008 and IPC-A-610E Class II electronic acceptance standards, we have the ability to undertake the installation tasks of precision components (such as 0201 SMT, BGA, tight pin ICs, etc.).

7. PCBA testing is a crucial step in ensuring the quality of production and delivery. FCT testing fixtures are made according to the testing points, procedures, and steps designed by the customer, and then the PCBA board is placed on the FCT testing rack to complete the testing. We can create our own PCBA test stand, equipped with engraving machines and test stand assembly engineers.

8. Equipped to meet the needs of customers for harsh environmental applications such as humidity, temperature, and corrosion, our professional three proof paint spraying production line includes fully automatic one-stop mode including spraying equipment, UV detection, and baking.

9. Our company specializes in configuring automatic gluing machines, which can help customers achieve one-stop PCBA packaging services. We have engineers with rich technical experience in sealing, and have unique experience in controlling foaming, unsightly molding, surface shrinkage, and dents in the sealing process.

10. We have rich experience in PCBA low-pressure injection molding and can provide customers with better user solutions.

11. A finished product assembly production line with nearly 30 assembly workers, 95% of whom are skilled workers, proficient in operation, high efficiency, excellent assembly quality, dedicated technical engineers, and scientific workstation design and management are conducive to efficiency improvement.

Electronic Manufacturing

Electronic manufacturing has become an indispensable part of the modern product chain, involving a wide range of fields, such as electronic product manufacturing, communication equipment manufacturing, automotive electronics manufacturing, medical equipment manufacturing, instrument manufacturing, smart home manufacturing, etc. The electronic manufacturing customer base of iPCB includes industries such as communication, aerospace, aviation, medical, industrial control, automotive, and power supply.

In order to further enhance the ability of electronic manufacturing and adapt to the characteristics of large quantities, diverse types, and different specifications of orders from different customers. iPCB continues to expand its scale production capacity and meet the diverse changes in customer demand. With the continuous acceleration of electronic manufacturing product upgrades, iPCB continues to maintain its technological innovation capability, improve process technology to meet the increasing demand for electronic manufacturing products.