With 15 years of PCB manufacturing experience, iPCB provides customers with high-quality PCB and low-cost FR4 PCB manufacturing.

According to the PCB equipment and PCB production conditions, PCB process basis, management level, and the PCB production process level of the iPCB, iPCB is customized as the basis for the iPCB to purchase orders, contract review, and engineering design.

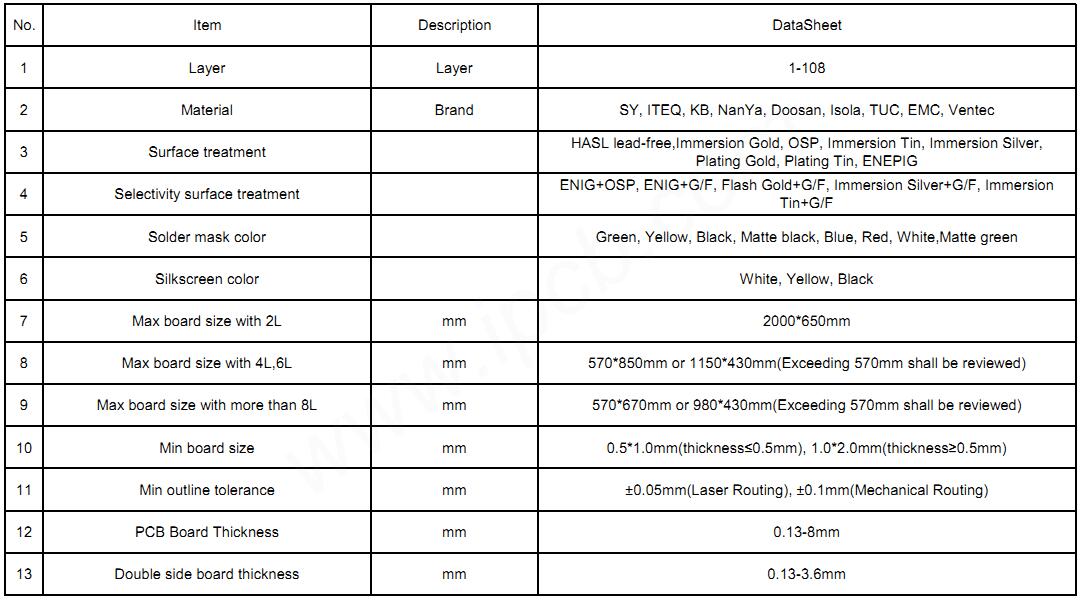

For more information on Standard PCB technics capacity, click Download Process Capability DataSheet to download the documentation. Please contact us if you have questions.

Printed wire board | Halogen-Free PCB(HF PCB) | Standard PCB |

Maximum layers of FR-4 PCB: 108 layers

Maximum production size: 2000 * 650mm (the size decreases after the number of layers increases), Can manufacture standard PCB board, HDI buried hole and blind hole PCB, multi-material mixed pressure PCB, high-frequency board, Rigid-flex PCB.

We use lines and solder resist direct imaging (LDI) for more precise control of lines High multi-layer PCB board and laser perforation direct plating blind hole filling, better PCB flatness. Use character printing to make the silk screen clearer.

Our PCB Research and Manufacturing Goals for the Next 2 Years

1. Advanced pulse plating, raising the high thickness diameter ratio to 48:1 or higher

2. The impedance control tolerance is reduced to ± 5% or more

3. The line width and line spacing shall be reduced to 25 / 25um

4. Continuously verify new PCB materials for high-order HDI PCB, high-speed low loss PCB, IC substrate and thinner and more precise applications

5. Research on deep micropores (thickness diameter ratio 1:1 or greater)

6. Research on metal core plate, conductive paste (Ormet and Tatsuta), copper paste plug hole technology

7. Process research of buried component PCB, such as buried capacity PCB, buried resistance PCB and buried magnetic PCB

Standard PCB Technics Capacity