PCB board production involves a series of complex and precise manufacturing processes. As the circuit boards become more integrated and more complex, the manufacturing process becomes more and more challenging for production personnel, and the probability of defects and failures also increases. Big.

Regardless of the reason, for personal use or commercial applications, PCB defects can cause serious adverse consequences. For example, circuit board failures in important medical equipment may be life-threatening, while problems with smartphones or automotive electronics can interfere with user activities .

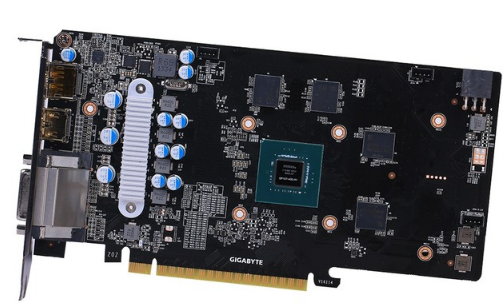

What are the common defects of PCB board?

Defects in PCB include solder bridges or different solder joints between component pins, short circuits between copper wires, open circuits, component displacement, and so on. In most cases, manufacturers will conduct extensive testing before launching their products on the market. However,

some defects may be overlooked, and the defects will only become obvious after the board is actually used by the user. In addition, due to the environment and other conditions beyond the control of the manufacturer, some defects may occur on site. In addition, some defects occur because they occur outside the scope of the manufacturer's controllable environment or other conditions.

short circuit

The types of short circuits in the production stage are not the same, while other short circuits occur, in the process of soldering or reflow soldering, common short circuits include:

When the space or spacing between copper traces is small, a short circuit will occur

The leads of components that are not trimmed can cause short circuits

Floating in the air can lead to short thin wires that can cause short circuits between copper traces

solder bridge

Component failure: A defective component usually shorts its input or output to power or ground.

open the way

When the trace is broken, or the solder is only on the pad and not on the component lead, an open circuit will occur. In this case, there is no adhesion or connection between the component and the PCB. Just like short circuits, these may also occur during the production process or during the welding process and other operations. Vibration or stretching of the circuit board, dropping them or other mechanical deformation factors will destroy the traces or solder joints. Similarly, chemical or moisture can cause solder or metal parts to wear, which can cause component leads to break.

loose or misplaced components

During the reflow soldering process, small parts may float on the molten solder and eventually leave the target solder joint. Possible reasons for the displacement or tilt include the vibration or bounce of the components on the soldered PCB board due to insufficient circuit board support, reflow oven settings, solder paste problems, and human error.

After the PCB board is used, problems often occur due to design or production defects. In most cases, the board will be at a low performance level or not work at all. When a problem occurs, identifying and fixing the fault is essential to ensure the continued use of the equipment. The success of the repair depends on the ability to identify the fault and its location.

Most PCB manufacturers have all the test equipment and tools to identify and correct circuit board failures. However, for some designers or professionals with limited resources, it is impossible to purchase all these tools. Fortunately, electronics professionals can use low-cost technology to identify and fix a considerable number of problems with basic tools and patience.