How do PCB manufacturers choose lead-free solders

For PCB manufacturers, although lead-free solder has not been widely used in the circuit board industry, the variety of patented formula products has long been confusing. And all kinds of brands can't say that they can pick up their own good words, and it makes people like a king who does not know what to do? In a short period of time, I want to correctly evaluate the long-term variety of mass production from the results of a few simple experiments. Can

Reliability, people don’t know what to do! The following are some recognized guidelines for lead-free solder selection:

◆Nontoxic of lead-free solder

◆The supply of lead-free solder is indispensable and the price is reasonable (Available and Affordable)

◆The plastic range of lead-free solder should be very narrow. Narrow Plastic Range (refers to tensile strength test)

◆The performance of lead-free solder (Acceptable Wetting)

◆The lead-free solder is a material that can be mass-produced (Material Manufacturable)

◆The manufacturing process temperature of lead-free solder is not too high and can be widely recognized (Acceptable Processing Temperature)

◆The solder joint reliability of lead-free solder is good (Form Reliable Joints)

Generally meet these conditions and can replace the current Sn63/Pb37 alloy solder. In the past few years,PCB manufacturers have paid more attention to the following formulas:

1. The tin-silver co-fusion gold Sn96.5/Ag3.5 of lead-free solder

The melting point of this two-phase alloy is 221 degree Celsius. It has been used for many years in the ceramic hybrid board industry (Hybrid), and it is most favored by the American NCMS, Ford, Motolora, and Japanese TI and German researchers. It is considered to be the most suitable solder to replace Snb. . However, some American industry players believe that the Wetting during the fusion welding process (Ref1ow) is very poor, and it is difficult to achieve perfect quality. This is

Because the surface tension is too high when it is in liquid state, the contact angle (Contact Ang1e) is too large, resulting in insufficient spreading properties (Spreadin g). However, the conductivity of this material is 30% higher than that of Sn63/Pb37, and the proportion is also lower than 12%. However, the coefficient of thermal expansion (CTE) is negatively higher than 20%.

Two, lead-free solder tin and copper co-fusion gold Sn99.3/Cu0.7

The melting point of this two-phase alloy is 227°C. The United States N O r t e 1 believes that its (wave soldering in nitrogen atmosphere) welding quality is almost on par with that of Sn63/Pb37 in telephone products. However, if solder paste soldering is performed in general air, not only the wettability will be worse, but the solder joints will also have a rough and textured appearance. Moreover, the mechanical strength is also quite good, and it is almost listed in various categories without

Lead solder is at the bottom of the list. However, due to the low price and the fact that oxidation is not easy to occur in the tin flow, and there is not much scum, N E M I of the United States believes that it is suitable for use in tin. When PCB manufacturers want to spray tin, this alloy should be a more suitable material. First

3. Lead-free solder tin-silver-copper eutectic alloy Sn/Ag/Cu

The eutectic temperature of this most mainstream three-phase alloy is around 217 degree Celsius (Sn3.5 A g 0.9Cu). There are as many as seven or eight kinds of approximate formulas with different weight ratios. The slurry range is extremely narrow, which is the current PCB The manufacturer recognized the best combined lead-free solder and the most likely general standard solder. The role played by a small amount of copper is:

(1) It can reduce the continuous increase of foreign copper in the solder joints.

(2) It can lower the melting point of solder.

(3) It can improve tin wetting, strengthen the durability of solder joints and heat fatigue resistance in the previous period.

There are more than 100 kinds of lead-free solder alloys in the literature. No matter in terms of solderability, solder joint strength and price comparison, any of them is much inferior to the current Sn63. From the evaluation and consideration of various conditions, it seems that the "three-phase eutectic of tin, silver and copper" will still be the slightly better one among the various rotten apples. Now it has become the favorite of the three aspects in Europe, America and Japan.

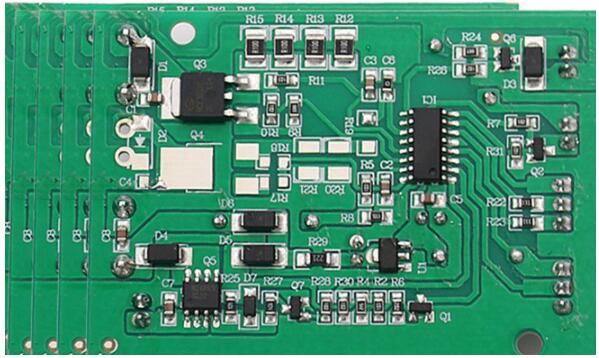

儿’The figure 2 below is the comparison of five lead-free solders on the surface of five lead-free solderable finishes.

5. Tin, silver, bismuth and other metals, the fourth alloy Sn/Ag/Bi/X

When bismuth is added to this alloy solder, the melting point will be lowered, and the solderability will be improved, and the solderability is almost the best among all lead-free solders. However, the trouble of "bismuth cracking" is prone to occur. And NCMS also said that bismuth-containing materials are prone to "through-hole ring tin filling cracking during wave soldering, but it is still preferred by Japanese manufacturers.

Of course, a large number of PCB manufacturers have to consider the cost of solder.