1. The characteristics of cost accounting for modern PCB companies

Accurate cost accounting has an important guiding role in the operation and development of enterprises, and can guide enterprise decision-making, improve business processes, and enhance the competitiveness of enterprises. Accurate cost accounting is mainly manifested in several aspects such as corporate pricing strategy reference, internal management control, and compliance with tax law requirements.

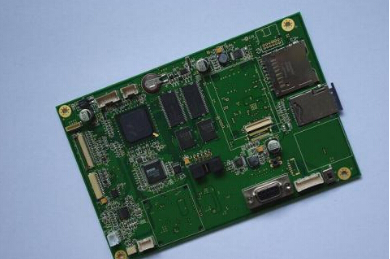

For modern PCB companies, cost accounting has its own unique characteristics and difficulties. Because printed board companies generally have the characteristics of a large number of orders, a limited number of orders, strict quality requirements, and short delivery cycles. The most important thing is that because of the long product process, the process and process parameters of different types of products have their own characteristics, resulting in very large differences in production costs.

Second, the general steps of PCB enterprise cost accounting

From the beginning of the production cost to the calculation of the total cost of the finished product and the unit cost of the entire cost calculation steps, the general procedure can have the following steps: First, the audit of the production cost is to check the non-compliance with the system and regulations. Stop it. The second is to determine the cost calculation objects and cost items, and open a detailed account of product cost. It is also necessary to summarize the various element expenses incurred, compile various element expense allocation tables, and allocate them according to their purposes and include them in the relevant production cost detailed accounts.

At the end of the month, a certain distribution method is adopted for distribution, and finally the total cost and unit cost of the product are calculated.

For PCB companies, product cost components can also be divided into three elements: direct materials, direct labor, and manufacturing costs.

1. Direct material cost

In the PCB industry, the material distribution process will hardly be distributed to each product according to the material quota table. Therefore, the use of cost sharing has become an important means of material cost accounting. The general process is: first obtain the output statistics record (in the PCB industry, the production area is generally used as an indicator), and then collect the monthly material summary, and allocate it to the output of different types of finished products at one time, and the standard material rate can be obtained. This amount can be regarded as the raw material quota table of the finished product. Specifically, when calculating the cost of each product, you only need to use the single area of the product * the standard material rate.

The PCB industry generally distinguishes between main materials and auxiliary materials. For example, copper plates, copper foils, inks, dry films, etc., which are of higher value and need to be paid attention to can be called main materials, and others can be called auxiliary materials. Companies with a relatively high level of management will introduce an important concept for the cost of main materials: the amount of thousand feet. The so-called thousand-foot consumption refers to the quota of materials consumed to produce a certain output (such as 1,000 square feet) of finished boards. That is, a bill of materials (BOM) for the type of finished product.

If a certain enterprise's millisecond dosage is set: each millifoot double-sided board needs 1,100 square feet of copper plate, which is about 80 sheets. For double-sided boards, the consumption of a single copper plate for each product is equal to: a single area (square feet) of 1000*80 (sheets), and its cost is: the consumption of a single copper plate is the unit price of each copper plate (yuan).

If a certain enterprise's thousand-foot dosage is set: 15 kilograms of ink is needed for each thousand-foot double-sided board produced. Then the cost of a single ink for each product is equal to: a single area (square feet) 1000 * 15 * unit price per kilogram of ink cost (yuan).

If a certain company sets the amount of micro-foot, 2100 square feet of dry film is required for each micro-foot double-sided board produced, which is about 3 rolls of dry film of 21*592'. Then the dry film cost of each product is equal to: single area (square feet) 1000 * 3 * unit price of dry film cost per roll (yuan).

2. Direct labor costs

There are two models of hourly wage or piece rate in the practice of corporate payroll management. Corresponding to cost accounting, it is necessary to extract the current month’s actual working hours statistics table, the current month’s output statistics table, and the individual (group) output statistics table to obtain a summary record of the workshop’s current monthly wages and bonuses.

Next, it is necessary to extract the monthly workshop output summary table and compare it with the salary and bonus payment summary records, so that the standard labor rate of the process can be calculated as an important indicator of cost accounting.

3. PCB manufacturing cost

The scope of manufacturing costs includes utilities, repairs, and depreciation of assets. How to accurately extract the above costs and allocate them to each product as accurately as possible is a big problem.

3.1 Drilling costs for manufacturing costs

For the PCB drilling process, the cost of the product is directly related to the number of holes, the size of the hole, and the ratio of the thickness to the hole. Therefore, many PCB companies have introduced "aperture single hole cost".

3.2 Surface treatment of manufacturing costs

The current common surface treatment processes are: spraying lead tin (hot air leveling), OSP (environmental protection board), spraying pure tin, tin, silver, gold and so on. The surface treatment process is different, the price will be different. The manifestation of the price can be dealt with by means of apportionment of manufacturing costs. That is to see whether the product has gone through a certain process, and if it has gone through, the manufacturing cost of that process will be added.

3.3 The amount of gold salt for manufacturing costs

Regarding the gold salt dosage and safety control, it is the focus of each PCB factory's management. For product cost calculation, the thickness and area of the gold plating are generally considered. Using this to calculate the amount of gold salt multiplied by the unit price of gold salt, the cost of gold salt amount can be obtained.

Three, summary

In summary, the particularity of PCB products determines the characteristics and difficulty of cost accounting. In order to achieve fast and effective cost management, it is recommended that the company's advanced information technology be assisted. By creating a calculation model suitable for the company in the computer system, fast and accurate cost accounting of PCB products and semi-finished products can be achieved.