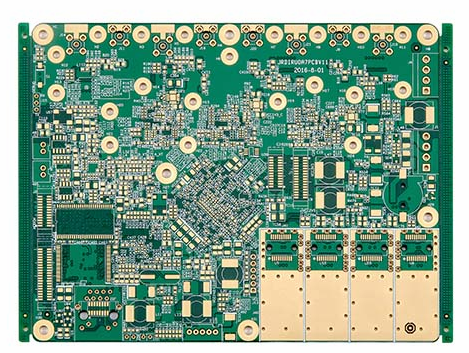

If you have ever disassembled an electronic device, you must have seen a small green rectangular tablet inside with densely connected wires. This is the famous PCB (Printed Circuit Board), the Chinese name printed circuit board. Because it is made by electronic printing, it is called a "printed" circuit board.

PCB can provide mechanical support and electrical connection for almost all electronic products. Its biggest advantage is that it can ensure the quality of electronic products and improve labor productivity. When the electronic equipment adopts the PCB, errors caused by manual wiring can be avoided, and the automatic insertion or placement of electronic components can be realized, which greatly saves manpower.

According to IPC's latest "2014 Global PCB Production Report" estimates, the global PCB output value reached 60.2 billion U.S. dollars in 2014, and the market is bright. But have you ever thought that perhaps one day PCB will die and come to an end?

Unexpected technological development can often change the course of the world and quickly occupy a dominant position. Many people call this phenomenon the "black swan of technology", such as transistors and the Internet. For example, you can own yourself for only a few hundred dollars. 3D printing in the mechanical prototyping laboratory.

Phil Gilchrist, vice president and chief technology officer of TEConnectivity, believes that the next field to be subverted by the "technical black swan" phenomenon is likely to be the current PCB field that is still very popular.

It is undeniable that PCB does have significant advantages, but it also has many disadvantages. Since the PCB is only a small flat hard board, the design is limited first. The connection design of the signal and the circuit must adopt a coplanar design, and it is difficult to cooperate with other components, which brings a lot of trouble to the designer; secondly, the transmission The signal capacity is limited. As the distance increases, the signal is bound to decay rapidly; third, in large-scale electrical equipment, the PCB forms a "wall", and the airflow is blocked and returned after encountering the PCB board, which seriously affects the equipment. Heat dissipation and cooling, not to mention using liquids to cool the equipment; fourth, due to material limitations, under high temperature conditions, PCBs are prone to warpage and damage. Once damaged, they must all be taken out, resulting in high maintenance costs.

Therefore, Phil Gilchrist predicts that the rise of power supply and data cable architecture may threaten the stability of PCB for many years.

Will the power supply and data cable architecture end the PCB era?

Unlike the PCB which must adopt a coplanar structure, the structure of the cable can be connected to the electronic components in any direction, and the cable can allow the power and data connectors to be connected to the position where they are needed. And because the signal transmission capacity limitation brought by PCB is removed, the interconnection distance between the connectors is greatly increased. Among them, the passive cable lengthens the interconnection length by at least four times, while the active optical cable reaches several kilometers. In addition, through the cable connection, the shape of the electronic device will not be limited by the PCB design, and the physical structure can be greatly reduced or completely redesigned. This also greatly changes some things that are considered normal in our daily life, such as Wearable devices, smart devices and portable devices, etc.

Furthermore, the cable structure does not form a "wall" like a PCB. Whether it is air or liquid, it can freely flow through the entire equipment, thereby speeding up the cooling of the equipment and reducing the thermal impact on the environment. In addition, cables are generally more durable than PCBs. The cable can still maintain excellent signal performance in high temperature and harsh environment. Even if there is a problem, the user only needs to unplug a component and replace it with a new one.

So, can cables really catch up with PCB boards in the future and end the glorious era of PCB design?