The through-hole reflow welding is a reflow welding process method for inserting components, which is mainly used for the manufacture of surface mount plate containing a few plug-ins. The technology is the application method of solder paste. According to the application method of solder paste, through-hole reflow welding can be divided into three types:

1. Tubular printing through-hole reflow welding process Tubular printing through-hole reflow welding process is the early application of through-hole component reflow welding process, mainly used in the manufacture of color TV tuner. The process is to use a tube printer for solder paste printing.

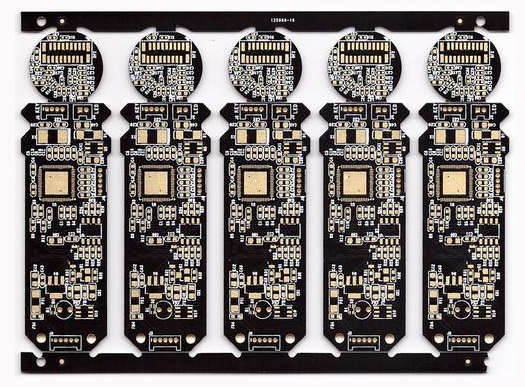

2. The solder paste printed circuit board through-hole reflow soldering process solder paste printing through-hole reflow soldering process is the more used through-hole reflow welding technology, mainly used for conventional PCBA, containing a small amount of plug-in technology with conventional flow welding process is fully compatible with again, do not need to special process equipment, the requirement is welded instrumentation components must be suitable for through-hole reflow soldering.

3. Forming tin sheet through hole re-flow welding process forming tin sheet through hole re-flow welding process is mainly used for multi-foot connector, solder is not solder paste but forming tin sheet, generally by the connector manufacturer directly add, assembly can only be heated.

For through-hole reflow welding, if the pin or pin does not expose PCB, it is easy to have hemispherical solder joints during reflow welding. Such solder joints are actually bad solder joints, mostly virtual solder joints, and the typical feature is that there is a large hole under the solder joints. If the length of the pin is smaller than the thickness of the PCB, the solder paste will not be "barrel" out, and the intermittent welding between the pin and the hole wall is formed to fill, and the hole is formed after welding.

Types of PCB through-hole reflow welding techniques and requirements for pins

Through hole recirculation welding has certain requirements on pins.

(1) Pins should generally extend 0.2? 0.8mm is suitable. Too long, is stuck to the pin end of the weld is difficult to be recycled into the hole during re-flow welding; If there is a lot of indentation, such as 0.5mm, it is easy to form a hemispherical appearance weld during reflow welding.

(2) If the design hope to achieve the pin does not expose the PCB surface, it is recommended to use the chamfer pin end design, and control the pin inlet size "0.5mm, in order to avoid the solder paste filling with gap after inserting the pin.