In order to meet the current terminal mobile phone 3D sensing, automotive LiDAR and optical fiber transmission needs, in recent years, the market for infrared components has gradually grown, and VCSEL chips have seen the most significant growth.

Since Apple released the iPhone X series in 2018, Android mobile phone manufacturers have opened up the layout of 3D sensing in all directions. According to public information, after OPPO released the first TOF camera in 2018, vivo, Huawei, Samsung, LG, Lenovo and other companies have also released models equipped with ToF cameras.

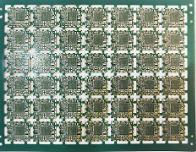

To this end, the PCB factory has assembled alumina ceramic circuit boards and aluminum nitride ceramic circuit boards that are more suitable for TOF technology.

Generally, the thermal conductivity of alumina ceramic circuit board is 17-23W/mK, but according to the special preparation method and material formula, the alumina ceramic circuit board can reach about 220W/mK; and the thermal conductivity of aluminum nitride ceramic circuit board It is 10 times that of alumina circuit board and can directly reach 170-230W/mK, providing customers with different options.

Whether it is alumina ceramic circuit board or aluminum nitride ceramic board, the line/spacing (L/S) resolution of its circuit board can reach 20μm, which can realize the integration and miniaturization of equipment, so as to achieve the small size of TOF camera., Light and thin rigid demand.

In addition to the trend of 3D sensing face recognition applications driven by Apple mobile phones, the current VCSEL components have gradually extended to the fields of automotive LiDAR, trying to replace the original more divergent EEL through the light energy concentration, beam angle and shape characteristics of VCSEL components. light source.

To this end, Stoneon has developed a ceramic circuit board that is more suitable for automotive LiDAR, to ensure that the thermal expansion coefficients of ceramics and chips are close, do not contain organic components, and have a long service life, and ensure that the breakdown voltage can be as high as 20KV/mm to ensure that Demand for VSCEL for vehicles.

In view of the vertical structure of VSCEL, the DPC thin film process technology is adopted to ensure that the bonding force between the metal layer and the ceramic is more stable, and the packaging effect of high flatness and high reliability vertical interconnection is better. Bit precision issues.

In addition, due to the recent fermentation of 5G issues, the related requirements of optical communication components, such as optical fiber data transmission capacity, bandwidth and distance, will also be the focus of subsequent development; and VCSEL components are trying to replace traditional LED light sources, providing wavelengths of 850nm and frequency. A wide range of 5~200Gbps optical fiber application modules to enhance the overall 5G transmission.

To this end, Stoneon uses DPC technology ceramic PCB to take advantage of its low dielectric constant and dielectric loss, good heat dissipation, conductive thickness can be customized within 1μm-1mm, and low high-frequency loss can be used for high-frequency circuit design and assembly, etc. Unique advantages to realize the expansion of VSCEL field and get optimized development and progress.

As a ceramic bracket enterprise for the core chip of VCSEL products, PCB factories should continue to develop better and more efficient ceramic circuit boards, become a solid supporter of the VCSEL market, and contribute to a smarter, more convenient and better life in the world.