About the influence of vias on signal transmission

The basic concept of vias

Via (Via) is one of the important components of multilayer PCB, and the cost of drilling usually accounts for 30% to 40% of the cost of PCB board manufacturing. Simply put, every hole on the PCB can be called a via.

From the perspective of function, vias can be divided into two categories: one is for electrical connection between layers; the other is for device fixation or positioning. For example, in terms of process, these vias are generally divided into three categories, namely blind vias (BlindVia), buried vias (BuriedVia) and through vias (ThroughVia). Blind vias are located on the top and bottom surfaces of the PCB and have a certain depth. They are used to connect the surface line and the underlying inner line. The depth of the hole usually does not exceed a certain ratio (aperture). Buried vias refer to the connection holes located in the inner layer of the PCB, which do not extend to the surface of the PCB. Theabove two types of holes are both located in the inner layer of the PCB, and are completed by a through-hole forming process before lamination, and several inner layers may be overlapped during the formation of the via. Through holes pass through the entire PCB and can be used to realize internal interconnection or as installation positioning holes for components. Because the Tongzi process is easier to implement and the cost is lower, most PCBs use it, and the other two types of vias are rarely used. The following via holes, unless otherwise specified, are considered as via holes.

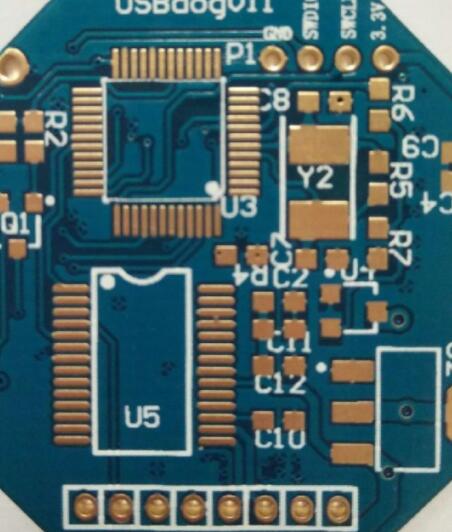

From a design point of view, a via hole is mainly composed of two parts, one is the center hole (DrillHole), and the other is the panel area around the hole, as shown in Figure 1-9-1. The size of these two parts determines the size of the via.

Obviously, in high-speed, high-density PCB design, designers always hope that the smaller the via hole, the better, so that more wiring space can be left on the PCB. In addition, the smaller the via, the smaller its own parasitic capacitance, which is more suitable for high-speed circuits. However, the reduction in hole size also brings about an increase in cost, and the size of vias cannot be reduced indefinitely. It is limited by process technologies such as drilling (Drill) and plating (Plating): the smaller the hole, the drill The longer the hole takes, the easier it is to deviate from the center position; and when the depth of the hole exceeds 6 times the diameter of the drilled hole, it cannot be guaranteed that the hole wall can be uniformly plated with copper. For example, if the thickness (through hole depth) of a normal 6-layer PCB is 50 mils, then under normal conditions, the minimum drilling diameter that the PCB manufacturer can provide can only reach 8 mils. With the development of laser drilling technology, the size of the hole can be smaller and smaller. Generally, a via with a diameter of less than 6 mils is called a micro-hole. Microvias are often used in HDI (High Density Interconnect Structure) designs. Microvia technology allows vias to be directly punched on the Via-in-Pad, which greatly improves circuit performance and saves wiring space.

Vias appear as breakpoints with discontinuous impedance on the transmission line, which will cause signal reflections. Generally, the equivalent impedance of the via is about 12% lower than that of the transmission line. For example, the impedance of a 50Ω transmission line will decrease by 6Ω when passing through the via (specifically, it is also related to the size and thickness of the via, not an absolute reduction). However, the reflection caused by the discontinuous impedance of the via is actually very small, and its reflection coefficient is only (50-44)/(44+50)≈0.06. The problems caused by the via are more concentrated on the parasitic capacitance and inductance. Influence.