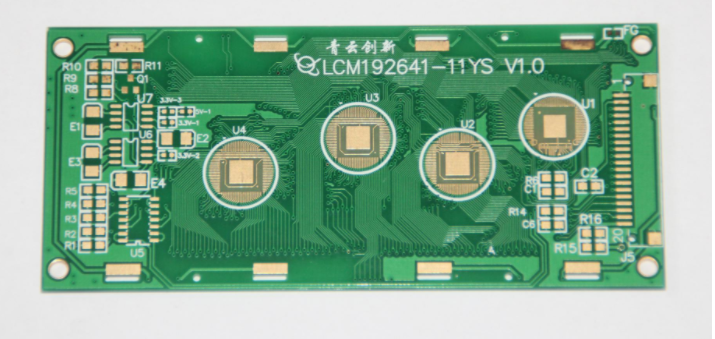

Circuit board electroplating technology

Circuit board electroplating technology: 1. Classification of electroplating process:

Acid clean copper electroplating nickel/gold electroplating tin

2. Process flow:

Acid dip-full board copper electroplating-graphic transfer-acid degreasing-secondary reverse rinsing-micro-etching-secondary-acid immersion-tin plating-secondary reverse rinsing -Nickel plating-Secondary washing-Citrate immersion-Gold plating-Recycling-2-3 pure water washing-Baking

Three, the process is explained clearly:

(1) Pickling

1. Utility and goal: remove oxygen compounds on the surface of the plate and activate the surface of the plate. The concentration of the ordinary liquid is at 5%, and some are maintained at about 10%. The main purpose is to avoid the introduction of nutrients and cause the sulphuric acid content of the bath to be uncertain;

2. The acid leaching time is not suitable for too long to avoid oxygenation of the board surface; after the use period, when the acid solution shows turbidity or the copper content is too high, it should be changed as soon as possible to avoid polluting the surface of the electroplating copper tank and the board;

3. C.P grade sulfuric acid should be used here;

(2) Copper electroplating on the whole board:

Also called copper, board electricity, Panel-plating

1. Utility and goal: try our best to take care of the thin chemical copper deposited just now, avoid the chemical copper being etched away by acid after oxygenation, and add it to a certain extent by applying current through plating

2. All-board copper electroplating related process parameters: the main components of the bath solution are copper sulfate and sulfuric acid. If it is deemed appropriate, use high acid and low copper to dispense according to the prescription to ensure the uniformity of the plate thickness distribution during electroplating and the deep plating of deep holes Experienced; the sulfuric acid content is mostly 180 g/l, and most of them reach 240 g/l; the copper sulfate content is generally about 75 g/l, and a trace of chloride ions is added to the bath as a gloss aid and copper light The gloss effect is displayed side by side; the amount of copper bright agent added or the opening amount is generally 3-5ml/L, and the addition of copper bright agent is generally based on the method of Qian'an hour or based on the actual production board effect; the current of the whole board electroplating The calculation is generally based on 2A/square decimeter multiplied by the size of the plated surface or surface of the object on the board. For the whole board, the board length dm*the board width dm*2*2A/DM2; the copper cylinder temperature is kept at Room temperature conditions, the normal temperature does not exceed 32 degrees, and often is controlled at 22 degrees, because the temperature is too high in the summer, the copper cylinder proposes to install a cooling temperature control system;

3. Process protection: Replenish the copper polish as early as possible according to thousands of hours every day, and add it according to 100-150ml/KAH; check whether the shower pump is working properly and whether there is air leakage; apply a clean wet wipe every 2-3 hours Clean and clean the negative conductive rod with a tablecloth; analyze the copper sulfate (1 time/week), sulfuric acid (1 time/week), and chloride ion (2 times/week) content of the copper cylinder every week, and try to get it through the Hall tank. Adjust the content of the light agent and replenish the relevant raw materials as soon as possible; clean the anode conductive rods and the electrical joints at both ends of the tank every week, and replenish the anode copper balls in the titanium basket as early as possible, and electrolyze 6-8 with a low current of 0.2-0.5 ASD. Hour; every month should check whether the anode titanium basket bag is damaged, and those who are damaged should be repaired as soon as possible; and check whether there is anode mud accumulated at the bottom of the anode titanium basket, and if necessary, it should be thoroughly cleaned and cleaned as soon as possible; and the carbon core should be used for 6-8 At the same time, the low-current electricity is removed to eliminate impurities; every six months or so, according to the pollution state of the tank, it is determined whether large disposal is required (active carbon powder); the filter element of the easy shower pump should be changed every two weeks;

4. Major disposal procedures: A. Take out the anode, pour out the anode, clean the anode film on the surface of the anode, and then put it in the barrel of the copper anode. Use a microetching agent to roughen the surface of the copper angle to an average pink color, and then wash and dry it., Put it into the titanium basket, and then put it into the acid tank for later use

B. Put the anode titanium basket and anode bag into 10% 100% lye and soak in water for 6-8 hours, wash and dry, then soak in 5% dilute sulfuric acid in water, wash and dry for later use;

C. Transfer the tank liquid to the spare tank, add 1-3ml/L of 30% preservative, start heating, wait until the temperature is increased to about 65 degrees and mix with open air, and mix with warm air for 2-4 hours;

D. Turn off the air mixing, press 3-5 g/L to dissolve the activated carbon powder into the bath liquid, after the dissolution is complete, open the air to mix, so keep warm for 2-4 hours;

E. Turn off the air and mix, heat up, and let the activated carbon powder slowly settle to the bottom of the tank;

F. When the temperature drops to about 40 degrees, use a 10um PP filter element and filter powder to pass the bath solution into a clean and tidy office tank, open the air to mix, put in the anode, hang into the electrolytic plate, press 0.2-0 .5ASD current density and low current electrolysis 6-8 hours,

G. After analysis and analysis, the sulfuric acid, copper sulfate, and chloride ion content in the debugging tank are within the normal operating range; the final result of the Hall tank trial is replenishing the light agent;

H. After the color of the surface of the electrolysis plate is averaged, the electrolysis can be stopped, and then the electrolysis green film treatment is performed according to the current density of 1-1. 5ASD for 1-2 hours, and an average fine and precise adhesion force is formed on the anode. A satisfactory black phosphorous film is enough;

I. Trial plating OK. OK;

5. The anode copper ball contains 0.3-0.6% 100% phosphorus. The main important item is to reduce the anode dissolution rate and reduce the initiation of copper powder;

6. When replenishing drugs, if the amount of addition is large, such as copper sulfate or sulfuric acid; after adding, electrolysis should be carried out at low current; when adding sulfuric acid, pay attention to safety, and when adding large amounts (above 10 liters), it should be divided into several times. Quickly add; otherwise it will cause the bath temperature to be too high, the decomposition of the light agent will speed up, and the bath will be contaminated;

7. The addition of chloride ions should be consciously added. Because the content of chloride ions is particularly low (30-90ppm), the addition must be done after the measuring cylinder or measuring cup is correctly weighed; 1ml of hydrochloric acid contains about 385ppm of chloride ions,

8. Formula for adding medicine: Copper sulfate (unit: kilogram) = (75-X) * tank size (liter)/1000 sulfuric acid (unit: liter) = (10%-X) g/L * tank size (liter) or (Unit: liter)=(180-X)g/L*tank size (liter)/1840 hydrochloric acid (unit: ml)=(60-X)ppm*tank size (liter)/385

(3) Acid degreasing

1. Objectives and effects: remove oxygen compounds on the copper surface of the circuit, the remaining glue of the ink residual film, and ensure the bonding force between the primary copper and the pattern electroplating copper or nickel 2. Remember the use of acid degreasing agent here, why not use alkali The degreasing effect of alkaline degreasing agent is better than that of acid degreasing agent? The main reason is that the graphic ink is not resistant to alkali and will destroy the graphic circuit. Therefore, only the acid degreasing agent can be used before the graphic electroplating.

3. Only control the concentration and time of the degreaser liquid at the time of production. The concentration of the degreaser liquid is about 10%, and the time guarantee is 6 minutes. A longer time will not have bad effects; the use of tank liquid is also based on 15 square meters. /L office fluid, the replenishment is based on 100 square meters 0.5-0. 8L;

(Four), micro-etching

1. Objectives and effects: Clean and roughen the copper surface of the circuit to ensure the bonding force between the patterned copper plating and the primary copper

2. The micro-etching agent is mostly considered appropriate and sodium persulfate is used. The coarsening efficiency is stable and average, and the washing performance is good. The sodium persulfate liquid concentration is generally controlled at about 60g/L, the time is controlled at about 20 seconds, and the drug is added at 100 3-4 kilograms per square meter; the copper content is controlled below 20 g/l; other protective cylinders are all corroded by sinking copper.

(5) Pickling

1. Utility and goal: Remove oxygen compounds on the surface of the plate and activate the surface of the plate. The concentration of the ordinary liquid is at 5%, and some are maintained at about 10%. The main purpose is to avoid the introduction of nutrients and cause the sulphuric acid content of the bath to be uncertain;

2. The acid leaching time is not suitable for too long to avoid oxygenation of the board surface; after the use period, when the acid solution shows turbidity or the copper content is too high, it should be changed as soon as possible to avoid polluting the surface of the electroplating copper tank and the board;

3. C.P grade sulfuric acid should be used here;

(6) Graphic copper plating: also known as secondary copper, copper plating on lines

1. Objective and utility: In order to satisfy the rated current load of each line, each line and hole copper needs to reach a certain thickness after copper plating, and the goal of line copper plating is to thicken the hole copper and line copper to a certain thickness as soon as possible;

2. Other items are the same as full board electroplating

ipcb is a high-precision,high-quality PCB manufacturer, such as: isola 370hr PCB, high-frequency PCB, high-speed PCB, ic substrate, ic test board, impedance PCB, HDI PCB, Rigid-Flex PCB, buried blind PCB, advanced PCB, microwave PCB, telfon PCB and other ipcb are good at PCB manufacturing.