Application of circuit board laser cutting machine under 5G technology

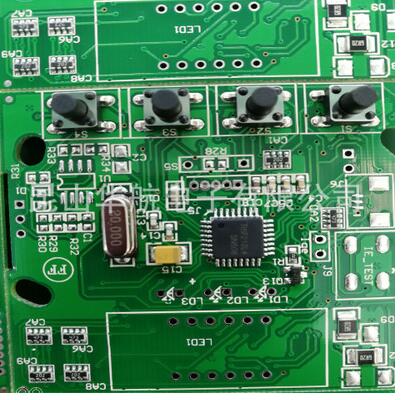

In some cities, the three major operators have begun to deploy 5G on a large scale. To realize 5G technology, it is inseparable from the use of circuit boards. In the electronics industry, flexible circuit boards can be said to be the blood vessels for electronic products. Especially under the trend of lighter, thinner, miniaturized, wearable, and foldable electronic equipment, flexible circuit boards have the advantages of high wiring density, lightness and thinness, bendable, and three-dimensional assembly, and are appropriately matched to the market development trend., Increasingly vigorous.

For processing, the common traditional processing methods are die, milling cutter, stamping and so on. However, this mechanical contact type splitting process is stressful, prone to burrs, dust, and insufficient precision, so it is gradually replaced by the laser cutting process. The flexible circuit board laser cutting machine is used as a non-contact processing tool. It can apply high-intensity light energy (650mW/mm2) on a small focal point (100-500UM). Such high energy can be used for laser cutting, drilling, marking, welding, scribing and other various materials. Kind of processing.

The use of flexible circuit board laser cutting machine to cut PCB/FPC does not require several molds like traditional stamping, which saves time and cost; and laser cutting is a non-contact processing, which eliminates the damage to components in contact processing such as mechanical stamping. To greatly improve the yield rate, the use of laser cutting PCB/FPC is an inevitable trend of development.

1. As the circuit density and pitch of FPC products continue to increase, and the contours of FPC graphics are becoming more and more complex, this makes it more and more difficult to make FPC molds. Laser cutting of flexible circuit boards uses CNC processing, without mold processing., Save the cost of mold opening;

2. Due to the deficiencies of mechanical processing, which restricts the processing accuracy, the laser cutting flexible circuit board adopts high-performance ultraviolet laser light source with good beam quality. Better cutting effect;

3. Because the traditional processing technology is a contact machining method. It will inevitably produce processing stress on the FPC, which may cause physical damage. Laser cutting of flexible circuit boards is a non-contact processing, which effectively avoids damage and deformation of processed materials.

With the development of flexible electronic technology, various electronic product applications have emerged. The application of flexible circuit board laser cutting machines will drive a trillion-yuan market, assist traditional industries to increase the added value of the industry, and bring revolutionary changes to the industrial structure and human life.

iPCB is happy to be your business partner. Our business goal is to become the most professional prototyping PCB manufacturer in the world. With more than ten years of experience in this field, we are committed to meeting the needs of customers from different industries in terms of quality, delivery, cost-effectiveness and any other demanding requirements. As one of the most experienced PCB manufacturers and SMT assemblers in China, we are proud to be your best business partner and good friend in all aspects of your PCB needs. We strive to make your research and development work easy and worry-free.

quality assurance

iPCB has passed ISO9001:2008, ISO14001, UL, CQC and other quality management system certifications, produces standardized and qualified PCB products, masters complex process technology, and uses professional equipment such as AOI and Flying Probe to control production and X-ray inspection machines. Finally, we will use double FQC inspection of appearance to ensure shipment under IPC II standard or IPC III standard.