How did the car light circuit board become the mainstream? According to the statistics of the US Department of Energy, the service life of LED PCB is 20-25 times that of traditional light sources and 10 times longer than that of halogen lamps. Compared with traditional light sources, the output brightness of the same power LED lamp is 3 to 4 times higher than that of ordinary bulbs and 2 to 3 times higher than that of halogen lamps. The use of LEDs can also help improve fuel economy and effectively reduce carbon dioxide emissions. The energy consumed by ordinary light bulbs is equivalent to 1.2g of carbon dioxide emissions per kilometer of driving, while LED lights are reduced to 0.58g.

However, the automotive circuit board project of the process LED lighting system is also relatively complicated. With the continuous maturity of LED lighting technology, the automotive industry has long been familiar with LED light sources for instrument panels and interior lighting, and LED lighting is gradually taking over brake lights., Fog lights, low beam lights, high beam lights, daytime running lights and adaptive front lights (AFS) and other exterior signal indications and headlight lighting applications. Although the use of LEDs in automotive lighting is of great benefit, there are still many problems to be overcome in system design, which also brings challenges to the design requirements of automotive circuit boards. Drue Freeman, vice president of global sales and marketing for the automotive electronics division of the internationally renowned semiconductor company NXP, pointed out that the challenge for LED applications in exterior lighting lies in the need for integrated, flexible and networked drivers.

The typical automotive lighting architecture relies on the body control module to control the lighting. The traditional light bulb solution only needs a switch to execute the commands of the body control module, and the control circuit is relatively simple. Once switched to the LED lighting solution, the lighting control circuit immediately became complicated. Since the color temperature, output luminous flux and ambient temperature of LEDs are closely related, MCU is required as the control center to adjust the brightness of LEDs in real time according to the ambient temperature and light signal, collect the information on the LEDs and feed them back to the body control module, thereby increasing the voltage regulation, Signal conditioning, temperature feedback, short circuit protection, electromagnetic filtering and a series of electronic devices. From cost considerations, compared to the traditional lighting source drive circuit, the cost of the LED architecture is higher; from the system design point of view, complex circuits invisibly increase the risk of the system, and the difficulty of troubleshooting electronic components also increases.

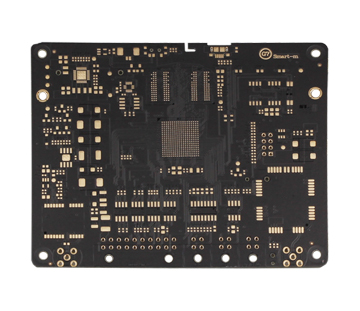

Therefore, improving the integration of the LED lighting control module not only reduces the space occupied by the chip on the car circuit board, but also helps to improve the system reliability and reduce the system expenditure by reducing the use of components in the circuit.

The fully integrated highly flexible driver chip introduced by NXP provides an effective solution for automotive circuit board manufacturers to solve the challenges brought by LED lighting, and finally makes LED lighting based on the new generation of automotive circuit board design technology mature and become an automobile. The mainstream of lighting applications.