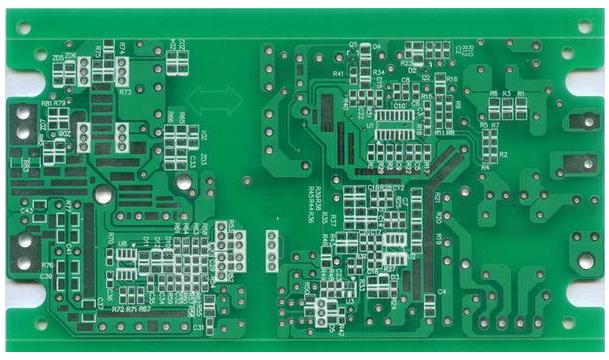

Generally, the assembly of electronic product PCBA must go through the SMT+THT process, during which it must go through wave soldering, reflow soldering, manual soldering and other soldering processes. No matter what method of soldering, the assembly (denso) process is the main one. Assemble the source of contamination.

Contaminants are defined as any surface deposits, impurities, slag inclusions and adsorbed substances that reduce the chemical, physical or electrical properties of PCBA to unqualified levels. There are mainly the following aspects:

(1) The components that make up the PCBA, the pollution or oxidation of the PCB itself, etc. will cause the PCBA board surface pollution;

(2) In the PCBA manufacturing process, solder paste, solder, solder wire, etc. are required for soldering. The flux in the soldering process will cause residues to pollute the PCBA board surface, which is the main pollutant;

(3) Hand marks will be produced during the manual soldering process. The wave soldering process will produce some wave soldering claw footprints and soldering tray (fixture) marks. The PCBA surface may also have different levels of other types of contaminants, such as Hole plugging glue, residual glue of high temperature tape, handwriting and flying dust, etc.;

(4) Pollution caused by dust, water and solvent vapors, smoke, small organic matter, and static electricity caused by charged particles attached to PCBA.

In the past, people's understanding of cleaning was not enough, mainly because the PCBA assembly density of electronic products was not high. It was believed that the flux residue was non-conductive, benign, and would not affect the electrical performance. Today's electronic assembly design tends to be miniaturized, smaller devices, smaller spacing, pins and pads are getting closer and closer, the gaps that exist are getting smaller and smaller, and pollutants may get stuck in the gaps. This means that if relatively small particles remain between the two pads, they may cause potential short-circuit defects.

According to the analysis and statistics of PCBA electrical equipment quality problems provided by China Saibao Laboratory's Reliability Research and Analysis Center, corrosion and electromigration caused by short-circuit, open circuit and other post-use failure problems accounted for 4%, which is one of the major killers of product reliability.

Pollution may directly or indirectly cause PCBA potential risks, such as the organic acid in the residue may cause corrosion to PCBA; the electric ions in the residue may cause the movement of electrons due to the potential difference between the two pads during the electrification process. It is possible to form a short circuit and cause the product to fail; the residue will affect the coating effect and cause problems such as inability to coat or poor coating; or it may not be found temporarily. After time and environmental temperature changes, coating cracks, The skin is warped, causing reliability problems.

It can be seen from the evolving electronic product market that modern and future electronic products will become smaller and smaller, and the requirements for high performance and high reliability will be stronger than ever. Thorough cleaning is a very important and highly technical work, which directly affects the working life and reliability of PCBA, and it is also related to environmental protection and human health.