Circuit board spacers are not only a core component for mechanical support but also play a significant role in electrical isolation, thermal management, and vibration protection. As electronic devices evolve towards miniaturization, higher density, and enhanced performance, the design and application of PCB spacers have become increasingly complex and diverse. This article will delve into the fundamental functions, material selection, design optimization, application scenarios, and future development trends of PCB spacers, aiming to provide comprehensive references for electronic engineers and designers.

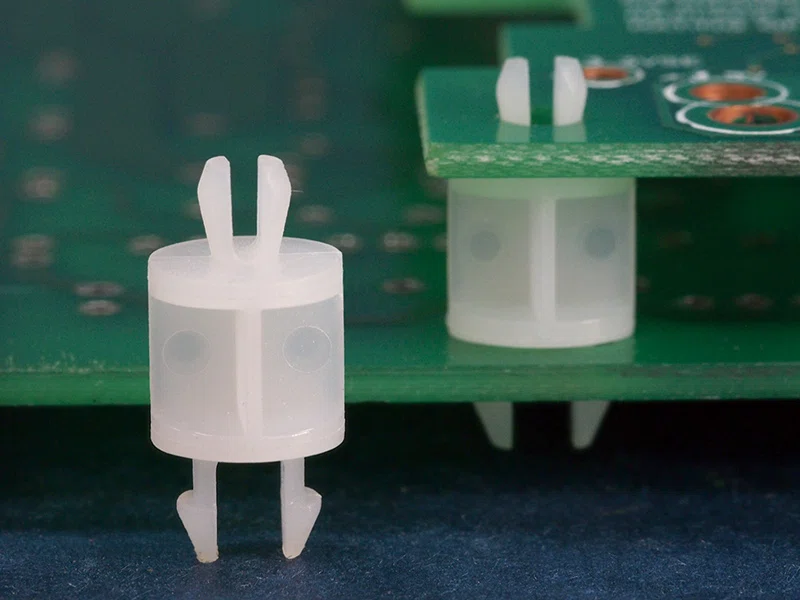

The primary function of Circuit board spacers is to provide mechanical support, ensuring that the circuit board remains stable within the device. They are typically installed at the edges or key support points of the circuit board to prevent displacement or deformation caused by external forces or vibrations. Additionally, PCB spacers can be used for isolation between multi-layer circuit boards, ensuring electrical insulation between different layers to avoid short circuits or signal interference.Depending on their shape and function, PCB spacers can be categorized into various types, including cylindrical spacers, square spacers, threaded spacers, and height-adjustable spacers. Each type has its specific application scenarios. For example, threaded spacers are suitable for situations requiring frequent disassembly and installation, while height-adjustable spacers are ideal for equipment with high installation precision requirements.

Material selection has a direct impact on the performance of PCB spacers. Common materials include nylon, polytetrafluoroethylene (PTFE), aluminum alloy, and stainless steel. Nylon is widely used due to its excellent insulation properties and low cost, but its mechanical strength and high-temperature resistance are relatively low. PTFE offers superior chemical corrosion resistance and electrical insulation, making it suitable for demanding industrial environments. Aluminum alloy and stainless steel are known for their high strength and durability, often used in applications requiring significant mechanical stress.In high-frequency circuit design, material selection is particularly critical. Since high-frequency signals are sensitive to dielectric constants and loss factors, choosing materials with low dielectric constants can effectively reduce signal loss and interference. Additionally, the thermal conductivity of materials is an important consideration, especially in high-power electronic devices, where good thermal conductivity can aid in heat dissipation and extend the device's lifespan.

Circuit board spacers

Design optimization of Circuit board spacersis key to ensuring their performance. First, the size and shape of the spacers need to be precisely calculated based on the thickness, weight, and installation environment of the circuit board. Spacers that are too small may not provide sufficient support, while oversized spacers can occupy valuable space, affecting the device's compactness. Second, the installation method of the spacers also requires optimization. Traditional installation methods include soldering, screw fixation, and snap-fit installation. Soldering is robust but difficult to disassemble; screw fixation allows for easy disassembly but requires additional tools and time; snap-fit installation combines convenience and reliability, making it suitable for mass-produced devices. Furthermore, surface treatment of the spacers is part of the design optimization. For instance, nickel or chrome plating can enhance the spacers' corrosion and wear resistance, while anodizing can improve the surface hardness and aesthetics of aluminum alloy spacers.

Circuit board spacers are widely used in various electronic devices. In consumer electronics such as smart phones, tablets, and laptops, spacers are typically used to secure the main board and battery, ensuring the device remains functional under impact or vibration. In industrial equipment, such as automated control systems and power electronics, spacers not only provide mechanical support but also need to exhibit excellent high-temperature and corrosion resistance. In the aerospace sector, the requirements for spacers are even more stringent. Since equipment must operate in extreme environments, spacers must withstand high and low temperatures, strong vibrations, and radiation. Therefore, aerospace applications often employ spacers made from high-performance materials and precision manufacturing processes.

With the continuous advancement of electronic technology, the design and application of PCB spacers are also evolving. In the future, spacers will increasingly focus on multifunctional integration. For example, spacers with integrated thermal management features can further enhance device heat dissipation efficiency through built-in thermal conductive materials or heat sinks. Additionally, the concept of smart spacers is emerging, where built-in sensors or electronic components can monitor the circuit board's temperature, vibration, and stress conditions in real-time, providing data support for device maintenance and fault diagnosis. In terms of materials, the application of new composite and nano mterials will bring new possibilities for spacer performance enhancement. For instance, carbon fiber composites offer high strength, low weight, and excellent thermal conductivity, making them ideal for high-performance electronic devices. Nano materials, through surface modification techniques, can further improve the wear and corrosion resistance of spacers.

The design and application of Circuit board spacers are continuously evolving. From basic mechanical support to multifunctional integration, and from traditional materials to new composites, the technological development of spacers reflects the electronics industry's pursuit of high performance and reliability. In the future, as electronic devices become further miniaturized and intelligent, PCB spacers will continue to play a crucial role, providing solid support for the advancement of electronic technology.