To understand PCB LED design, we first need to understand the working principle of LED. LED is a solid-state semiconductor device that emits light by releasing energy to generate photons when electrons and holes recombine. Different semiconductor materials and manufacturing processes determine the key characteristics of LED, such as color, brightness, and luminous efficiency. For example, common blue LEDs usually use gallium nitride (GaN) materials, and achieve efficient blue light emission by precisely controlling the doping concentration and crystal structure of the material. In white LEDs, blue LEDs are often used to excite yellow phosphors to mix white light. In this way, the performance and distribution of phosphors have an important impact on the quality of white light, such as color temperature and color rendering index.

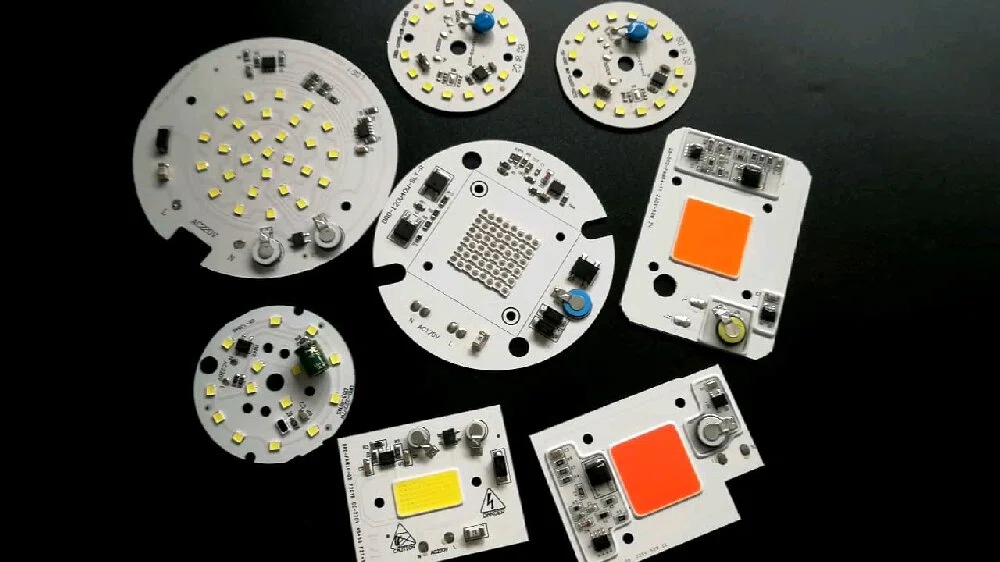

When PCB LED design, there are several basic elements that need to be considered. The first is layout. According to the number, type, and application requirements of LEDs, their positions on the PCB should be reasonably arranged. For example, in lighting applications, in order to achieve uniform lighting effects, LEDs are usually arranged according to a certain spacing and arrangement. Common layouts include matrix and circular layouts. Next is the circuit design, which requires precise calculation and design of the width, length and direction of the wire to ensure that the current can be evenly distributed to each LED, while minimizing the line resistance and inductance, reducing power loss and signal interference. The third is the heat dissipation design, choosing the right heat dissipation material and structure, such as using a metal substrate (MCPCB), adding heat dissipation fins, etc., to improve the heat dissipation efficiency and ensure that the LED works within the appropriate temperature range.Such as voltage regulator diodes, fuses, etc., can effectively prevent LED damage caused by power supply abnormalities and improve the reliability of the system.

PCB LED design

The stage of the PCB LED design is the most critical, and errors may mean that the circuit is defective or faulty. Creating a simple LED board circuit should be very simple. However, when you have to make more complex and high-performance types, the situation changes. Use these rules to perfect your design.

1. LED circuit boards generate a lot of heat and require practical thermal management design. In this regard, we recommend the following:

(1)Use materials that conduct heat effectively, such as aluminum or other metal cores

(2)Consider using large copper fills and attaching thermal pads to them

(3)Properly space components to prevent heat buildup

(4)Use thermal vias in multilayer boards to transfer heat

(5)In high-power circuits, include heat sinks and other cooling features

2. LEDs on PCB boards will only operate as required if they are connected to the correct power supply and drive circuits or other control components. Ensure the following points during the design phase:

(1)The power supply and control circuits match the LED voltage and current requirements or ratings

(2)Add surge and overcurrent protection devices such as fuses and bypass or decoupling capacitors

(3)Place the drive circuit close to the LED and LED pads to avoid losses and voltage drops

(4)Ensure proper grounding techniques and use appropriate trace sizes

(5)Ensure the inclusion of PCB test points

3. Follow proper practices when laying out and routing, otherwise the LED PCB assembly process may fail. Improper layout may also cause operational issues later.

(1)Route power and ground to the LED first before control signals

(2)Separate power from signal traces and avoid stubs to prevent interference

(3)If designing an SMD LED PCB board, place the chips together to make assembly easier

LED PCB designs offer a variety of options, are adaptable, cost-effective, and efficient, qualities that allow them to be used in many environments. Most applications are in the world of lighting. Most modern lights use light-emitting diodes, and this PCB type is standard for many lamps, from home lamps to those installed in offices and commercial or industrial facilities. Today, outdoor lighting is also gradually becoming LED-based. In the automotive field, LEDs are widely used, and most car lights use this technology. These PCBs are the backbone of advertising and other displays, supporting light-emitting chips and providing excellent heat dissipation capabilities.

In the context of global advocacy of green environmental protection, PCB LED design will also pay more attention to environmental protection. Future designs will use more environmentally friendly materials, such as degradable substrate materials, lead-free solder, etc., to reduce pollution to the environment. At the same time, by optimizing the design to improve the luminous efficiency of LEDs, reduce energy consumption, and achieve energy conservation and emission reduction. For example, developing new semiconductor materials and manufacturing processes to improve the photoelectric conversion efficiency of LEDs, so that LEDs consume less electricity at the same brightness.

In summary, PCB LED design runs through the entire process from the recognition of basic principles to the application of key technologies, and then to multi-scenario application practices and future trend prospects. It integrates multidisciplinary knowledge and continuously breaks through technical levels such as heat dissipation, electrical, and optical to meet the needs of different fields such as lighting, display, and automobiles. In the future, with the advancement of the trend of intelligence, integration, and green environmental protection, LED PCB will continue to innovate in the field of electronic technology, create a better, more efficient, and environmentally friendly light environment for mankind, and promote related industries to a new stage of development.