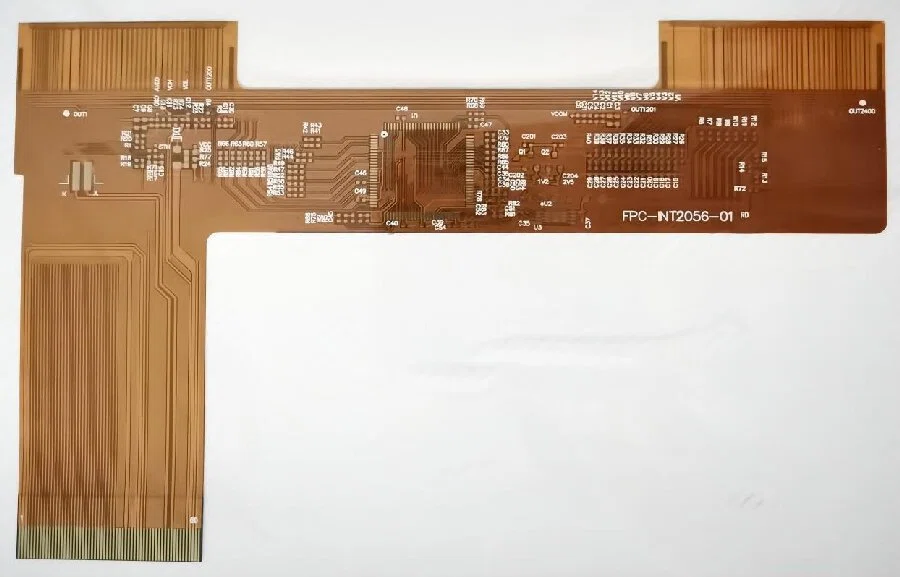

Cable PCB is a special electronic component that combines traditional printed circuit boards with flexible cables. Its basic structure typically consists of an insulating substrate, conductive traces, connection interfaces, etc. The insulating substrate, as a supporting carrier, serves to isolate and protect the conductive traces. Common materials include polyimide (PI), polyester (PET), etc. These materials possess good flexibility, electrical insulation, and chemical stability, enabling them to adapt to different usage environments and process requirements.

Cable PCBhas many unique performance advantages compared with traditional rigid PCBs. Firstly, its excellent flexibility allows for flexible wiring in confined spaces, adapting to various complex shapes and structures. For example, inside a smartphone, it can bend and bypass other components to achieve efficient connections between components such as the display screen, camera, and motherboard. This greatly saves space and improves the device's integration level. Secondly, it has good bend - resistant performance. Through special process treatment and material selection, it can withstand multiple bends without line breakage or performance degradation. Thirdly, performs outstandingly in signal transmission. By optimizing the circuit design and material selection, it can effectively reduce signal interference and attenuation, ensuring stable signal transmission. In addition, it is lightweight and thin, which is of great significance for electronic devices that pursue lightweight and miniaturization.

The manufacturing process of Cable PCB is relatively complex and involves several key steps. First is the treatment of the substrate. The insulating substrate needs to undergo pre - treatments such as cleaning and activation to ensure its surface cleanliness and adhesion, laying a good foundation for subsequent circuit fabrication. Next is the fabrication of the traces. Common methods include the etching method and the printing method. After the trace fabrication is completed, the installation of the connection interfaces is required. This step demands precise positioning and welding processes to ensure reliable electrical connections between the interfaces and the traces. For some high - precision connectors, automated welding equipment is usually employed for installation to improve welding quality and production efficiency. Moreover, to enhance its performance and reliability, a series of post - treatment processes are necessary, such as surface coating and curing. Surface coating can use materials like solder masks to protect the traces from oxidation, corrosion, and mechanical damage. The curing process can strengthen the bonding force between the substrate and the traces, improving the product's stability.

Cable PCB

In the consumer electronics field, it is an indispensable connecting element in devices such as smartphones, tablets, and laptops. For example, in a smartphone, it is used to connect the display screen to the motherboard, the camera to the motherboard, and the battery to the motherboard, enabling signal transmission and power supply among various components. In the automotive electronics field, it is widely used to connect components such as the car's dashboard, in - car entertainment system, and autonomous driving sensors, ensuring the stable operation of the automotive electronic system. In the industrial automation field, it is commonly used to connect components such as controllers, sensors, and actuators of various automation equipment. In complex industrial environments, such as high - temperature, high - humidity, and strong electromagnetic interference conditions, it ensures reliable signal transmission. In the medical equipment field, for devices such as CT scanners and magnetic resonance imaging (MRI) machines, it is used to connect components such as detectors and image - processing units, ensuring high - speed and accurate transmission of image data, providing a reliable basis for doctors' diagnosis.

Although Cable PCB has been widely applied in the electronics field, with the continuous development of electronic technology, it also faces some challenges. On the one hand, as the requirements for miniaturization and high - performance of electronic devices become increasingly higher, it needs to continuously improve integration and signal transmission performance while further reducing size and weight. This poses higher requirements for manufacturing processes and material research and development. On the other hand, the increasingly stringent environmental requirements also affect its production and application. Traditional manufacturing processes may use some environmentally harmful chemicals, such as lead - containing solder and certain organic solvents. In the future, it is necessary to develop more environmentally friendly manufacturing processes and materials to meet the needs of sustainable development.

Facing these challenges, its development shows the following trends: Firstly, it is developing towards higher density and smaller size. By adopting advanced manufacturing processes such as micro - via technology and multi - layer board technology, closer trace layout and higher integration can be achieved. Secondly, improve signal transmission performance by developing new materials and circuit designs to meet the needs of high - speed and high - frequency signal transmission in applications such as 5G and high - speed data centers. Thirdly, pay attention to environmental protection by using lead - free solder, biodegradable materials, etc., to reduce the impact on the environment. Fourthly, develop towards intelligence by integrating sensors, chips, etc., into the PCB, enabling it to have certain intelligent monitoring and control functions.

In conclusion, Cable PCB, as a key link in electronic connections, plays an irreplaceable role in modern electronic devices. In the future, with the continuous progress of electronic technology, it will continue to innovate and develop, providing stronger support for the performance improvement and function expansion of electronic devices, demonstrating its unique value in more fields, and promoting the electronic information industry to new heights.