How to prepare pcb board to meet the complex requirements of different electronic devices is a key topic in the field of electronic manufacturing. Next, let's explore all aspects of this technology in depth.

How to prepare pcb board. Before starting any actual operations, clarifying the design requirements of the PCB board is the primary task. This requires close cooperation with electronic engineers, product designers, etc., to deeply understand the functions, performance indicators, size limitations, and expected usage environments of the final products. For example, for a high - performance gaming laptop, its PCB board needs to have a strong signal - transmission capacity to support high - speed data processing and graphics rendering. At the same time, considering the compact size of the laptop, various electronic components need to be reasonably arranged within the limited space. For outdoor - used electronic devices, such as smart cameras, their PCB boards need to have good waterproof, dust - proof, and anti - harsh - environment capabilities.

The substrate is the basic support material of the PCB board, and its performance directly affects the electrical, mechanical, and reliability of the PCB board. Common substrate materials include copper - clad laminates (CCL), which can be divided into different types according to their materials and characteristics. Among them, the most commonly used is epoxy glass - cloth - based copper - clad laminate (FR - 4), which has good electrical insulation, mechanical strength, and dimensional stability, and is suitable for most conventional electronic devices. For high - frequency circuits, such as 5G communication equipment, polytetrafluoroethylene (PTFE) - based copper - clad laminates are usually selected because they have extremely low dielectric constants and dielectric losses, which can effectively reduce signal attenuation and distortion during transmission. In addition, there are some special substrate materials, such as ceramic substrates, which have excellent heat - dissipation performance and are often used in high - power electronic devices, such as high - power LED driver power supplies.

How to prepare pcb board

How to prepare pcb board. Pattern transfer is a key step in transferring the designed PCB layout pattern onto the copper - clad substrate. Currently, the commonly used pattern - transfer methods are photolithography and screen - printing. Photolithography utilizes the photosensitive properties of the photoresist to transfer the pattern on the mask plate onto the copper - clad substrate through processes such as exposure and development. This method has high precision and is suitable for making high - precision and high - density PCB boards, such as smartphone motherboards. Screen - printing directly prints the pattern made of ink onto the copper - clad substrate through screen - printing. It has simple equipment and low costs, but the precision is relatively low, making it suitable for some PCB boards with low - precision requirements, such as ordinary household - appliance control boards.

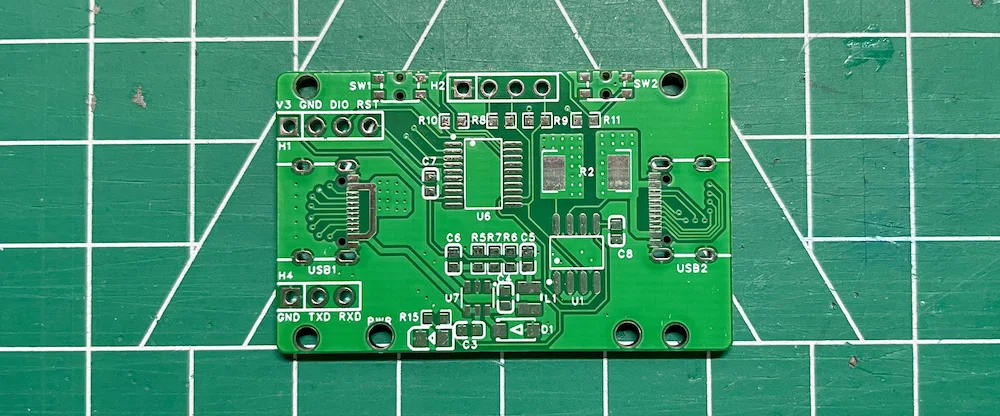

After electroplating is completed, the solder - masking and silk - screening processes are required. The solder - masking process involves coating the solder mask on the PCB board and then curing the solder mask in areas that do not need to be soldered through processes such as exposure and development. The silk - screening process is to print the silk - screen ink on the PCB board to form various marks and characters. The quality of the solder - masking and silk - screening processes directly affects the appearance and manufacturability of the PCB board. During the operation, attention should be paid to controlling the thickness, uniformity, and curing conditions of the solder mask and silk - screen ink to ensure the quality of the solder - mask layer and silk - screen layer.

How to prepare pcb board. Visual inspection is the first step of quality inspection. Observe the surface of the PCB board with the naked eye or a magnifying glass to check for issues such as short - circuits, open - circuits, missing components, offsets, and defects in the solder - mask and silk - screen layers. Although visual inspection is simple, it is a very important step, and many obvious quality problems can be discovered and repaired in a timely manner through visual inspection. Electrical performance testing comprehensively examines the electrical performance of the PCB board, including line resistance, insulation resistance, capacitance, inductance, signal - transmission characteristics, etc. Commonly used electrical - performance testing equipment includes multimeters, oscilloscopes, network analyzers, etc. Through electrical performance testing, it can be ensured that the electrical performance of the PCB board meets the design requirements, avoiding electrical failures during subsequent assembly and use.

In the process of preparing the PCB board, continuously optimizing the manufacturing process is the key to improving product quality and production efficiency. By optimizing the process parameters of pattern transfer, etching, drilling, electroplating, etc., such as adjusting the exposure time, etching - solution concentration, drilling rotation speed, etc., the stability and precision of the process can be improved, and the scrap rate can be reduced. At the same time, adopting new manufacturing processes and technologies, such as Laser - Direct - Imaging (LDI) technology and Build - Up technology, can also improve the manufacturing precision and performance of the PCB board to meet the requirements of continuously evolving electronic devices for PCB boards. With the continuous development of electronic technology, the performance requirements for PCB - board materials are getting higher and higher. Therefore, continuously improving and developing new materials, such as substrate materials with low dielectric constants and high thermal conductivity, high - performance copper foils and solder masks, etc., is an important way to improve the performance of PCB boards. At the same time, choosing environmentally friendly materials to reduce environmental pollution is also the future trend of PCB - board material development. In the design stage of the PCB board, by optimizing the layout and wiring, such as using multi - layer board design, rationally planning the power layer and ground layer, and optimizing the signal - transmission path, etc., the electrical performance and reliability of the PCB board can be improved. At the same time, using Computer - Aided Design (CAD) and Computer - Aided Engineering (CAE) software to simulate and analyze the design of the PCB board, discovering potential problems in advance and optimizing them, can also improve the quality and efficiency of the design.

In conclusion, how to prepare pcb board is a complex process involving multiple links and fields. From pre - planning and design, material selection, implementation of manufacturing processes, quality inspection, to optimization and improvement in the later stage, each link needs to be strictly controlled to ensure that the quality and performance of the PCB board meet the requirements of electronic devices. With the continuous development of electronic technology, the preparation technology of PCB boards is also constantly innovating and progressing. In the future, we look forward to the emergence of more high - performance, high - precision, and high - reliability PCB boards to provide stronger support for the development of electronic devices.