APT 1400 Flying Probe is an advanced testing system that significantly enhances efficiency and accuracy in PCB manufacturing. As the complexity of electronic devices continues to grow, traditional testing methods can no longer meet the increasing demands.Flying Probe’s fixtureless technology provides a more flexible and efficient solution for the PCB industry, particularly excelling in small-batch, multi-variety production scenarios.

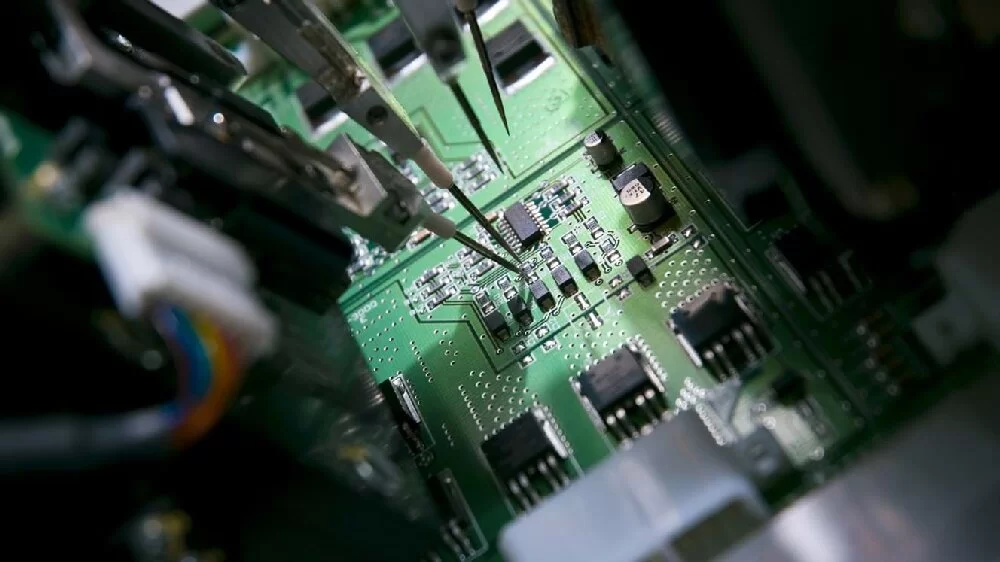

APT 1400 Flying Probe uses flying probe technology to rapidly and precisely test the electrical performance of PCBs. This innovative method eliminates the need for traditional test fixtures and relies solely on a set of movable probes to perform the tests. This approach not only reduces production costs but also shortens the product development cycle, making it especially suitable for small businesses and R&D projects. Additionally, the flexibility of this testing method makes it ideal for complex multilayer PCBs, allowing seamless detection across different layers to ensure every connection point is in optimal condition.In high-speed, high-density PCB testing, Flying Probe particularly stands out. With electronic products becoming smaller and more powerful, PCB designs are increasingly miniaturized, requiring testing equipment with higher resolution and precision. Equipped with advanced optical positioning systems, the APT 1400 Flying Probe can accurately locate even the smallest test points and swiftly adjust probe positions, ensuring higher precision without compromising efficiency.

In PCB production, testing is a critical step to ensure product quality. Flying Probe excels not only in testing speed but also in supporting various testing tasks such as open/short circuit testing, capacitance and resistance measurement, and signal integrity verification. Thanks to its high-precision positioning system, the equipment can quickly locate each test point and provide accurate data analysis. This is particularly crucial for industries requiring high-reliability circuits, such as aerospace, automotive electronics, and medical devices. Additionally, this equipment excels in handling high-layer or flexible PCBs. Flexible PCBs, due to their unique design and materials, present greater challenges for testing equipment. However, with its adaptable probe design, APT 1400 Flying Probe can easily meet these requirements. It can precisely test on curved surfaces and perform operations while maintaining the integrity of flexible materials. This makes it highly attractive in fields like wearable technology and consumer electronics.

APT 1400 Flying Probe’s robust software support is another key advantage. Its built-in software allows the automatic generation of test programs by importing CAD files, reducing manual programming time and error rates. Additionally, users can customize test parameters according to their needs, such as increasing the number of tests for specific nodes or setting sensitivity levels for specific areas. This flexibility greatly simplifies the testing process for different PCB types and improves overall production line efficiency.

For small-batch production, APT 1400 Flying Probe offers significant cost advantages. Traditional fixture testing requires custom fixtures for each product, often resulting in high costs and long lead times. Flying probe testing, however, eliminates the need for fixtures, relying on probes to flexibly test all points. This fixtureless testing method not only reduces equipment switching time but also enables quick responses to market demands, particularly advantageous for industries with fast product iteration cycles.Furthermore,Flying Probe demonstrates outstanding environmental performance. Its fixtureless testing approach significantly reduces the generation of waste fixtures, and the equipment itself is optimized for energy efficiency. These eco-friendly advantages align with modern green manufacturing principles while helping businesses save more on long-term operational costs.

In conclusion, APT 1400 Flying Probe, with its advanced technology, flexible operation, and high performance, has become an indispensable tool in PCB testing. From prototype development to mass production, it provides reliable support, helping businesses improve product quality and reduce time-to-market. The introduction of Flying Probe marks a new era in PCB testing technology, injecting more possibilities into the electronics manufacturing industry.