What is pcb circuit? It is a fundamental and indispensable component in the realm of electronics. A printed circuit board (PCB) circuit serves as the backbone that interconnects various electronic components, enabling them to function in harmony and perform specific tasks. It has revolutionized the way electronic devices are designed, manufactured, and assembled.

The history of PCB circuits dates back several decades. In the early days, the concept was gradually evolving. As time progressed, the manufacturing techniques of PCB circuits became more refined. In the 1950s, with the resolution of issues related to the bonding strength and solder resistance of copper-clad laminates (CCL) and laminate materials, industrial-scale production became feasible. The copper foil etching method emerged as the mainstream manufacturing process, leading to the widespread use of printed circuit boards. This era also saw the production of single-sided PCBs. In the 1960s, the mass production of double-sided PCBs with plated-through holes was achieved, further expanding the capabilities and applications of PCB.

What is pcb circuit? The 1970s witnessed a remarkable growth in multilayer PCB circuits. Multilayer PCBs started to develop rapidly, continuously striving for higher precision, density, finer lines and holes, enhanced reliability, lower cost, and automated continuous production. This trend was driven by the increasing complexity and miniaturization demands of electronic devices. The 1980s brought about a significant shift with the rise of surface mount technology (SMT), which gradually replaced through-hole PCB assemblies and became the mainstream production method. Ultra-high multilayer PCBs and high-density interconnect (HDI) circuit boards also experienced rapid development during this period.

What is pcb circuit?

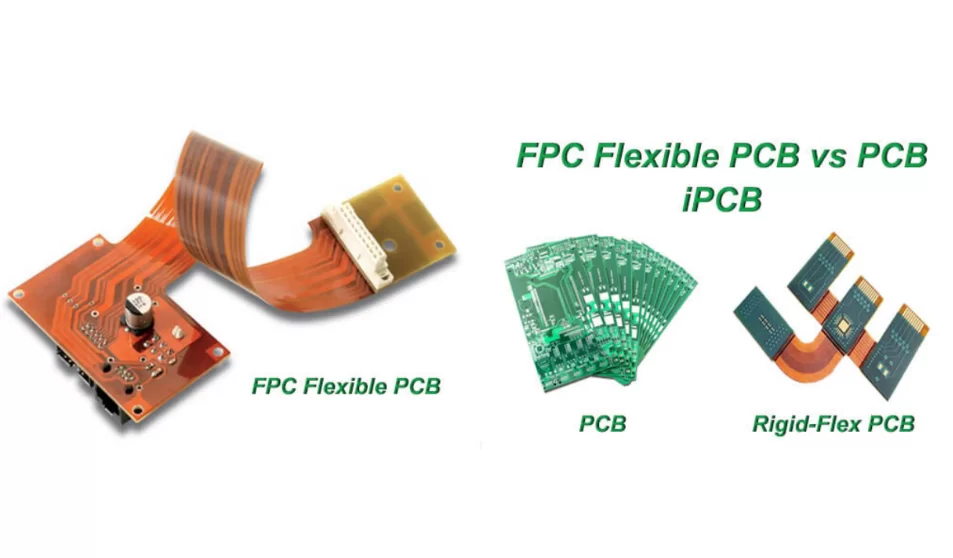

What is pcb circuit?The classification of PCB circuits is diverse. Firstly, based on application, there are civilian PCBs used in consumer products like toys, cameras, televisions, mobile phones, and home appliances. Industrial PCBs are employed in equipment such as security systems, automobiles, computers, communication devices, and industrial controllers. Military PCBs are crucial for aerospace, radar, warships, and military communication equipment. In terms of substrate material, there are paper-based PCBs (including phenolic paper-based and epoxy paper-based), glass cloth-based PCBs (such as epoxy glass cloth-based and polytetrafluoroethylene glass cloth-based), synthetic fiber PCBs (like epoxy synthetic fiber), organic film substrate PCBs (e.g., nylon film), ceramic substrate PCBs, metal core-based PCBs (such as iron, aluminum, and copper substrates), hydrocarbon PCBs, ceramic powder PCBs, and PTFE/Teflon/polytetrafluoroethylene PCBs. Structurally, they can be divided into rigid PCBs, flexible PCBs, and rigid-flex PCBs. According to the number of layers, there are single-sided, double-sided, multilayer, and HDI boards.

What is pcb circuit? The structure of a PCB circuit is complex and well-designed. It mainly consists of a copper-clad laminate (CCL), prepreg, copper foil, solder mask, and character layer. The CCL, which is a composite material of a dielectric layer (resin and glass fiber) and a high-purity conductor (copper foil), serves as the foundation, providing functions such as conduction, insulation, and support. The prepreg, mainly composed of resin and reinforcing materials (often glass fiber cloth), is essential for multilayer PCB production. Copper foil, either rolled or electrolytic, acts as the conductive layer. The solder mask, usually green but sometimes in other colors, protects the circuit from moisture, corrosion, and mechanical damage and prevents incorrect soldering. The character layer is used for annotation, facilitating the installation and maintenance of PCBA.

Surface treatment of PCB circuits is also a crucial aspect. Since bare copper is prone to oxidation and contamination, various surface treatment processes are employed. These include lead-free and leaded HASL (hot air solder leveling), organic solderability preservatives (OSP), electroless nickel immersion gold (ENIG), immersion silver, immersion tin, and gold finger plating. With the tightening of environmental regulations, leaded HASL is being phased out, and most PCB manufacturers now produce boards compliant with RoHS and, in some cases, halogen-free PCB processes.

What is pcb circuit? It is the cornerstone of modern electronics. Its evolution over the years has enabled the development of smaller, more powerful, and more reliable electronic devices. From the simplest consumer gadgets to the most complex aerospace and military systems, PCB circuits play an essential role. Their ability to provide mechanical support, electrical interconnection, and protection for electronic components has made them an integral part of the electronics manufacturing process. As technology continues to advance, PCB circuits will undoubtedly continue to adapt and evolve, further driving the innovation and progress of the entire electronics industry.