Printed circuit transformers are an integral part of modern electronic devices, especially in applications that require high efficiency, miniaturization, and high reliability. They not only reduce the size and weight of the device, but also reduce manufacturing costs and complexity by integrating directly into the PCB. The applications of this transformer technology cover a wide range of fields, from consumer electronics to industrial control systems.

When designing Printed circuit transformers, electrical properties and physical constraints must be considered. First, the transformer design must provide efficient magnetic coupling, which can be achieved through precise winding design, material selection, and PCB layout. Transformer windings are typically printed directly onto the PCB substrate using a high-precision printing process using copper foil, which not only simplifies the manufacturing process but also improves reliability.The PCB transformers manufacturing process utilizes a variety of technologies, including laser engraving, multilayer stacking technology, and high-density bonding, among others. Manufacturers must ensure that every step is precise to achieve the expected electrical insulation and efficiency. High-quality PCB materials such as FR-4 or premium materials such as polytetrafluoroethylene (PTFE) are essential for performance.

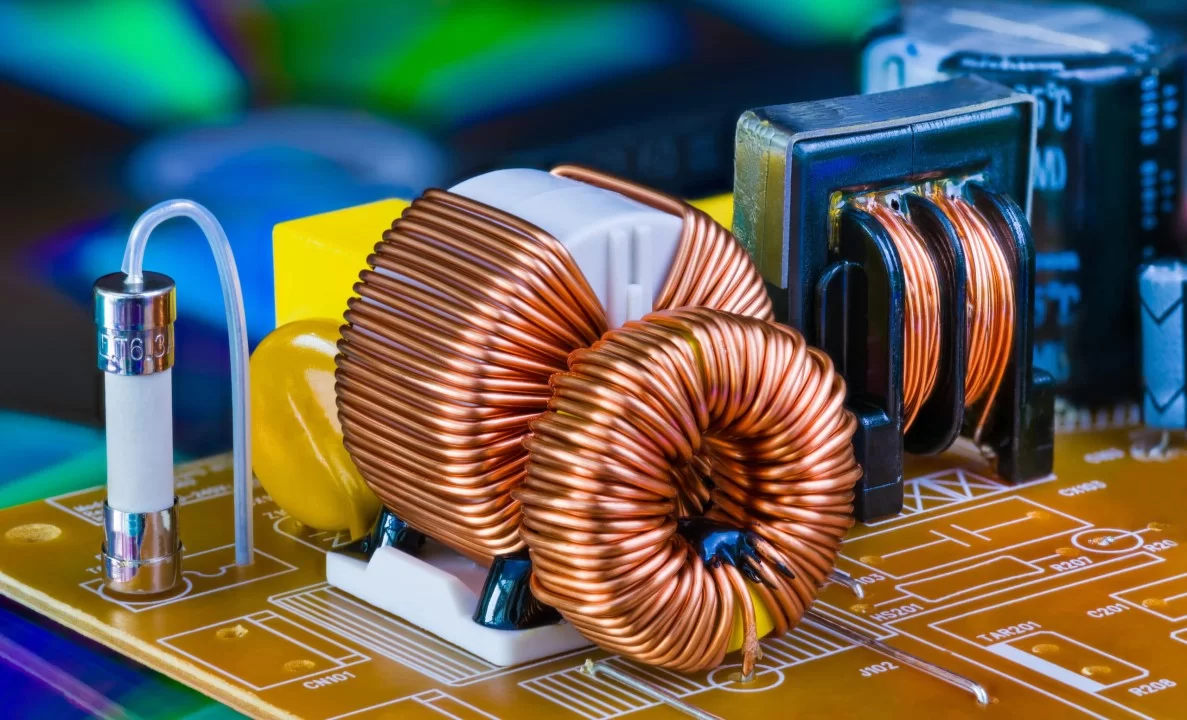

Printed circuit transformers

Printed circuit transformershave their own characteristics in different applications. They are widely used in switching power supplies and are used to isolate input and output terminals to improve safety and efficiency. In communication devices, PCB transformers are used to isolate and transmit signals to ensure data integrity. In medical devices, the precise insulation properties of the transformer ensure patient safety.Performance testing is very important for PCB transformers, including measuring parameters such as turns ratio, efficiency, leakage inductance, and insulation voltage. These tests not only confirm the functionality of the transformer but also test its durability in different environments such as high temperature, low temperature, and high humidity.

As electronic technology has advanced, PCB transformers have also led to many innovations. For example, integrated magnetic technology integrates transformers, inductors and capacitors directly on a single PCB, further reducing the number of components and space requirements. This design is particularly popular in power management and RF applications as it provides an efficient solution for managing complex signal paths. In addition, PCB transformers are becoming increasingly important in high frequency applications. High frequency transformers require low losses and high core efficiency. This has led to the research and application of new magnetic materials such as ferrites and nanocrystalline materials to optimize the efficiency of high frequency signal transmission and reduce heat loss.

The future of Printed circuit transformers is full of possibilities. With the development of Internet of Things (IoT) devices and 5G technology, the demand for miniaturization, high efficiency and high reliability continues to increase, and transformer PCBs will continue to play an important role. In the future, we may see more integration of passive components on PCBs to form what is called a “system PCB” in which all necessary electrical functions are integrated on a single PCB. In addition, environmental friendliness and sustainability will also become a design consideration. The use of more environmentally friendly materials and manufacturing processes to reduce the impact of e-waste will be an important direction in transformer PCB design. PCB transformers have also begun to be widely adopted in the emerging field of electric vehicles. The power management system of electric vehicles requires efficient energy conversion and isolation. The application of PCB transformers in this regard can not only reduce the system size, but also improve energy efficiency, thereby extending the vehicle's range. The design of the transformer also needs to consider electromagnetic compatibility to avoid interference between the motor and the power electronics system.

Printed Circuit Board transformers play an integral role in modern electronics technology, providing significant advantages, from increasing device efficiency and reliability to reducing cost and size. With the advancement of technology and the demand for higher performance, the design and application of PCB transformers will continue to evolve to meet the needs of future electronic equipment. Whether in consumer electronics, industrial applications or medical devices, PCB transformers will continue to be a critical component of circuit design.