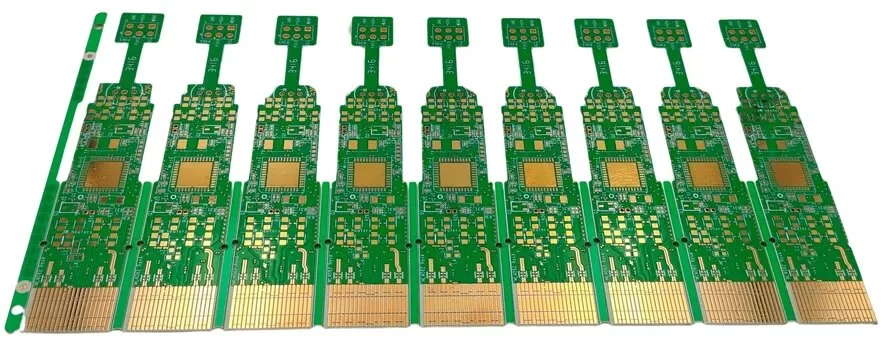

HF PCB (high frequency printed circuit boards) play an important role in the field of modern electronic technology.With the rapid development of wireless communications, radar, satellite communications and other technologies, the demand for high-frequency printed circuit boards is also increasing day by day.High frequency PCB refer to special high-frequency electromagnetic printed circuits used in the fields of high frequency (frequency greater than 300 MHz or wavelength less than 1 meter) and microwave (frequency greater than 3 GHz or wavelength less than 0.1 meters werden.Es this is a printed circuit board manufactured by using part of the ordinary rigid printed circuit board manufacturing process or by using a special processing method on the microwave substrate laminate coated with copper.

The performance of HF PCB depends largely on the materials used. These sheets have different characteristics and application scopes:

1.Rogers Sheet: Rogers Corporation is a leading global supplier of high-frequency materials, and its products are widely used in wireless communications, radar, satellite communications and other fields. Rogers sheet has the characteristics of low DK, low DF, high heat resistance, high chemical resistance, etc., which are suitable for high-performance high-frequency PCB design.

2.Tacony Sheet: Its products have good electrical and mechanical properties. Tacony sheet has low DK and DF values, and the thermal expansion coefficient matches well with copper foil, which is suitable for the manufacture of high-frequency PCBs.

3.Isola Sheet: It has excellent electrical properties and reliability. Isola sheet has stable DK and DF values, low water absorption, good chemical resistance and peeling resistance, and is suitable for high-frequency PCB applications in various harsh environments.

4.Arlon Sheet: It has a wide range of applications, including wireless communications, medical equipment, industrial control, etc. Arlon sheet is characterized by low DK and DF values, good heat resistance and chemical resistance, and is suitable for high-performance high-frequency PCB design.

5.SY sheet: SY sheet has stable performance and relatively low price, and is suitable for some high-frequency PCB applications with high cost requirements.

6.Panasonic sheet: It has good electrical performance and reliability. Panasonic sheet has low DK and DF values, and its thermal expansion coefficient matches well with copper foil, which is suitable for high-frequency PCB manufacturing.

High-frequency PCB

Advantages of HF PCB

1. High-frequency PCB has a small dielectric constant and a small loss. Advanced induction heating technology can achieve the target heating needs with very high efficiency. At the same time, high-frequency PCB also has environmentally friendly characteristics, which is very suitable for the development direction of today's society.

2. The transmission rate is inversely proportional to the square root of the dielectric constant, which means that the smaller the dielectric constant, the faster the transmission rate. High-frequency PCB uses special materials, which not only ensures the characteristics of small dielectric constant, but also maintains stable operation, which is very important for signal transmission.

3. High-frequency PCB is widely used in various industries that require heating treatment of precision metal materials. In the process of its field, not only can the heating of components of different depths be achieved, but also the heating can be focused on local characteristics, whether it is surface or deep, concentrated or dispersed heating pipes, can be easily completed.

4 High-frequency PCB made of materials with extremely low water absorption can challenge humid environments, and also has the advantages of resisting corrosion from chemicals, moisture resistance, high temperature resistance and great peeling strength, allowing high-frequency PCB to play a powerful role.

Application fields of HF PCB

1.High-frequency PCB has a wide range of applications in the field of wireless communication. Whether it is mobile devices such as mobile phones, tablets, and laptops, or communication equipment such as base stations, routers, and switches, high-frequency PCB is required to realize the transmission of wireless signals. The low loss, high transmission rate and good stability of high-frequency PCB can ensure the quality and reliability of wireless communication.

2. The radar system requires high-frequency PCB to detect and track targets. The high frequency and high precision of high-frequency PCB can meet the requirements of radar system for signal transmission. At the same time, the good heat resistance and impact resistance of high-frequency PCB can adapt to the working needs of radar system in harsh environments.

3. Satellite communication requires high-frequency PCB to realize signal transmission between ground stations and satellites. The high frequency and high transmission rate of high-frequency PCB can ensure the quality and efficiency of satellite communication. At the same time, the low loss and good stability of high-frequency PCB can adapt to the working needs of satellite communication in space environment.

4. High-frequency PCB is also widely used in the field of medical equipment. For example, magnetic resonance imaging (MRI) equipment, ultrasonic diagnostic equipment, radiofrequency ablation equipment, etc. all require high-frequency PCBs to achieve signal transmission and processing. The low loss, high transmission rate and good stability of high-frequency PCBs can ensure the accuracy and reliability of medical equipment.

5.High-frequency PCBs also have important applications in the field of industrial control. For example, automated production lines, robot control systems, sensor networks, etc. all require high-frequency PCBs to achieve signal transmission and processing. The high frequency and high transmission rate of high-frequency PCBs can meet the real-time requirements of industrial control. At the same time, the good heat resistance and impact resistance of high-frequency PCBs can adapt to the working needs of industrial control in harsh environments.

HF PCB has broad application prospects and development potential as a key component in the field of modern electronic technology. The technology of high-frequency PCB will continue to innovate and improve, and develop towards higher frequency, lower loss, higher transmission rate, better stability, smaller size, lighter weight, higher integration and intelligence, green and environmental protection, etc