FR4 TG plays a critical role in the performance and reliability of PCBs. Just as the substrate material is fundamental to the overall function of the PCB. The performance, durability, and reliability of PCBs depend heavily on the properties of the substrate material used. PCBs can be classified into two main categories based on the nature of their substrates: organic substrates and inorganic substrates. Each type has its own set of characteristics and applications, determined by factors such as working temperature, frequency, and mechanical strength.

FR-4 is a widely used composite material consisting of woven glass fiber cloth and epoxy resin. The term "FR-4" refers to the specific grade of material used for the fiberglass cloth. It is an extremely common material in the electronics manufacturing industry because of its excellent electrical, mechanical, and chemical stability. Additionally, FR-4 is highly insulating and resistant to high temperatures, making it ideal for high-temperature and high-pressure environments. The standard thicknesses for FR-4 boards on the market are 1.6mm and 1.2mm, though they can be customized in length and width depending on customer requirements.

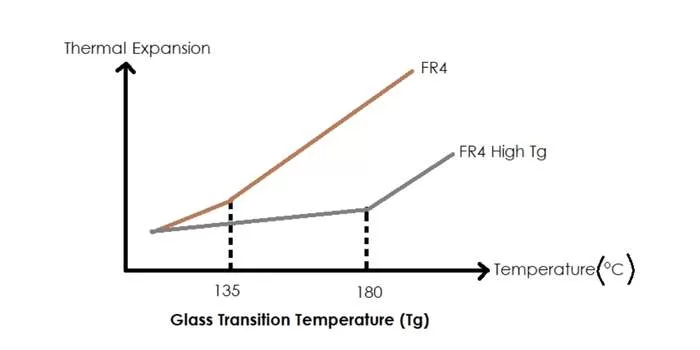

FR4 TG, especially in high-performance applications, is crucial to ensuring that PCBs can handle the high operating temperatures of modern electronics. One of the key properties of the resin material used in FR-4 is its Glass Transition Temperature (Tg). This refers to the temperature point at which the material transitions from a rigid, "glassy" state to a more flexible, rubbery state. When the temperature is below the Tg, the material is in a hard, glass-like state. When the temperature exceeds the Tg, it becomes soft and flexible like rubber.For years, the Tg value has been a critical parameter for classifying the grades of FR-4 substrate material. Typically, the higher the Tg, the more reliable the material. For example, standard FR-4 material with a Tg of around 135°C is often used in consumer electronics like motherboards, while higher Tg materials with Tg values of 180°C are used for more demanding applications like CPU motherboards, DDR3 memory substrates, and IC packaging substrates.

FR4 TG

FR4 TG materials are not only important for thermal stability but also for their influence on the mechanical and electrical properties of the PCB. The use of high Tg materials in PCB manufacturing is gaining momentum globally, especially in industries requiring high-performance electronics, such as telecommunications, automotive, and industrial control systems. High Tg PCBs offer several benefits over standard Tg PCBs, though they do come at a higher cost.Some of the key advantages of high Tg PCBs include:

1.Better adhesion and mechanical strength

2.Stronger moisture resistance and lower water absorption

3.Dimensional stability

4.Higher thermal decomposition thresholds

5.Increased chemical resistance

6.Enhanced heat resistance and thermal stress tolerance

7.Longer lifespan for the PCB laminates

8.Improved reliability in plated through-holes (PTH)

9.Lower coefficient of thermal expansion (CTE) along the Z-axis

If a PCB cannot tolerate high thermal loads, particularly if its Tg is 25°C lower than the operating temperature, a high Tg PCB becomes necessary for safe and reliable operation. This is particularly relevant in applications where the operating temperature regularly exceeds 130°C.The shift towards high Tg PCBs is driven in part by the increasing adoption of RoHS-compliant (Restriction of Hazardous Substances) PCBs, which require lead-free solder that must be applied at higher temperatures. Consequently, more PCB manufacturers are transitioning to high Tg materials to meet the demands of these lead-free solder processes.

FR4 TG needs to be taken into account in PCB design.When designing a PCB, choosing a material with an appropriate Tg value is essential. The specific Tg value required depends on the operating conditions of the device, such as whether it will be exposed to low or high temperatures. Other factors to consider include thermal expansion, electrical properties, mechanical strength, and resistance to high temperatures.For high-performance applications, it is critical to select a high Tg material that ensures the PCB's reliability and durability, especially under thermal stress. Many industries are shifting toward high Tg materials for applications in advanced communication systems, industrial control panels, and computing systems, where thermal management is a significant concern.

In conclusion, FR4 TG represents the future of PCB material development as industries move toward more complex and powerful devices.the substrate material plays a crucial role in determining the performance and reliability of a printed circuit board. With the growing demand for more powerful and compact electronic devices, the importance of selecting the right substrate material—whether organic or inorganic—cannot be overstated. High Tg PCBs are becoming increasingly prevalent in the global electronics market, offering numerous advantages for applications requiring high thermal resistance and durability. Any questions? Please notify us.