The Ego battery circuit board is a critical component in contemporary portable power devices. These circuit boards are designed not just for power transmission but also for intelligent management, significantly extending battery life and ensuring operational safety. Particularly in high-performance power tools and other portable devices, the Ego battery PCB stands out with its superior performance, intelligent management systems, and robust design, making it a preferred choice within the industry.

Ego battery circuit board utilizes the latest power management technologies to ensure stable power output across various usage scenarios. By integrating advanced power management ICs (Integrated Circuits), the board can intelligently adjust current and voltage, preventing damage to the battery from overcharging or discharging. Additionally, the design of the Ego battery PCB allows it to meet the high power demands of devices, thereby enhancing overall system efficiency and reliability.Ego battery PCB is also distinguished by its excellent heat dissipation capabilities, a crucial advantage during prolonged high-load operations. Overheating is one of the primary issues faced by battery-operated devices under intense usage, but the Ego battery PCB mitigates this risk through an optimized thermal management system. The heat dissipation design includes high-efficiency thermal conductive materials and thermocouple sensing technology that monitors battery temperature in real-time, adjusting power output promptly to prevent potential safety hazards.

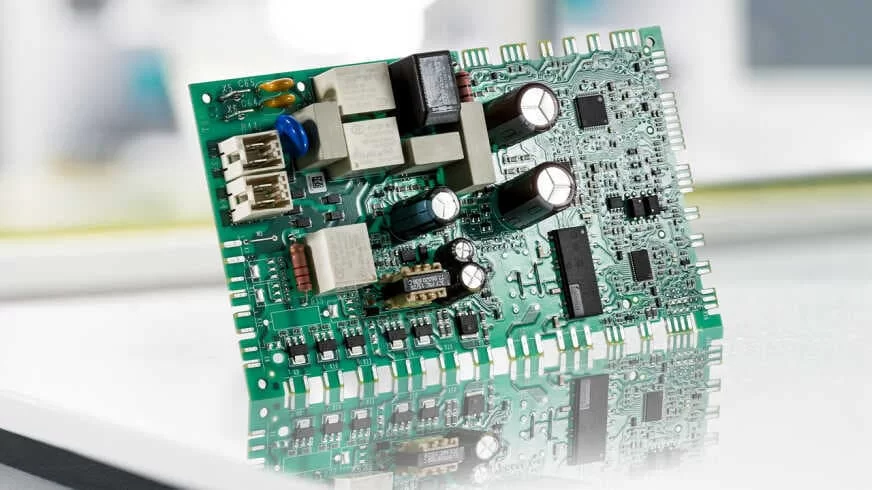

Ego battery circuit board

Ego battery circuit board has also made significant advancements in smart technology. A variety of integrated sensors monitor the battery's operating status in real-time, including parameters like current, voltage, and temperature. Using this data, the system can dynamically adjust the battery's operating mode, such as automatically switching to a power-saving mode when the battery is low or increasing current output under high load demand. This smart management not only enhances the overall performance of the device but also extends battery life, reducing maintenance costs.

Design-wise, the Ego battery PCB also takes into account shock resistance and protective features to ensure stable operation even in harsh environments. The board's materials consist of high-strength composites that are both lightweight and possess excellent impact resistance. This protective design is especially critical in dusty or humid work environments, as it helps prevent corrosion and damage from external factors, thereby extending the board’s lifespan. The use of conformal coatings is another layer of protection, shielding the sensitive circuitry from moisture, dust, and other contaminants that could degrade performance over time. Additionally, the board’s layout is meticulously planned to minimize electromagnetic interference (EMI), which can be a significant issue in dense electronic assemblies. This meticulous design approach not only enhances the durability and reliability of the battery circuit board but also ensures that it meets stringent industry standards and certifications, such as those from Underwriters Laboratories (UL) or the International Electrotechnical Commission (IEC).

Ego battery circuit board is optimized for mass production without compromising quality. Advanced manufacturing techniques such as surface-mount technology (SMT) and automated optical inspection (AOI) are employed to ensure that each board meets precise specifications and performance criteria. These manufacturing processes are supplemented by rigorous testing protocols, including functional testing, in-circuit testing (ICT), and environmental stress screening (ESS). Such comprehensive testing regimes ensure that the Ego battery PCBs can withstand the demands of real-world applications, from the rigors of daily use in power tools to the exacting requirements of professional-grade equipment.With increasing environmental awareness, Ego battery PCBs have also invested heavily in green design. By optimizing circuit design and using eco-friendly materials, these boards reduce their environmental impact during manufacturing. Moreover, the high efficiency of Ego battery PCBs means lower energy consumption, which not only benefits users but also reduces carbon emissions, contributing to environmental protection.

Overall, the Ego battery circuit board has secured an essential place in modern portable power devices due to its exceptional power management, superior heat dissipation, intelligent design, and durable construction. As technology continues to evolve and application scenarios expand, the Ego battery PCB will keep leading innovations in power tools and portable devices, offering users more reliable and efficient power solutions.