Flex on board is a key concept in modern electronic design that focuses on the configurability and adaptability of components and circuits during the circuit design and manufacturing process.This flexibility not only enhances the efficiency of design,but also facilitates the realization of product diversity,enabling products to better meet the ever-changing needs of the market.

In a rapidly evolving technology environment,flex on board greatly enhances product competitiveness.Designs with flexibility allow for rapid iteration and customization,resulting in shorter development cycles and thus quicker response to market changes.In addition,it can help reduce production costs and enable expansion by reusing pre-qualified modules,eliminating the need for additional testing and certification.

Flex on board is used in a wide range of applications,including consumer electronics,industrial automation,and medical devices.In consumer electronics,flexible circuit designs enable products that are more attractive and novel experiences in terms of form and function.For example,recent wearable devices often utilize flexible circuits to provide a more comfortable wearing experience.In medical devices,on-board flexibility ensures that devices can operate efficiently and meet rapidly changing medical needs.

Considering flex on board during the design process of a flexible circuit board is an important factor in ensuring the performance and adaptability of the final product:.

1.Material Selection

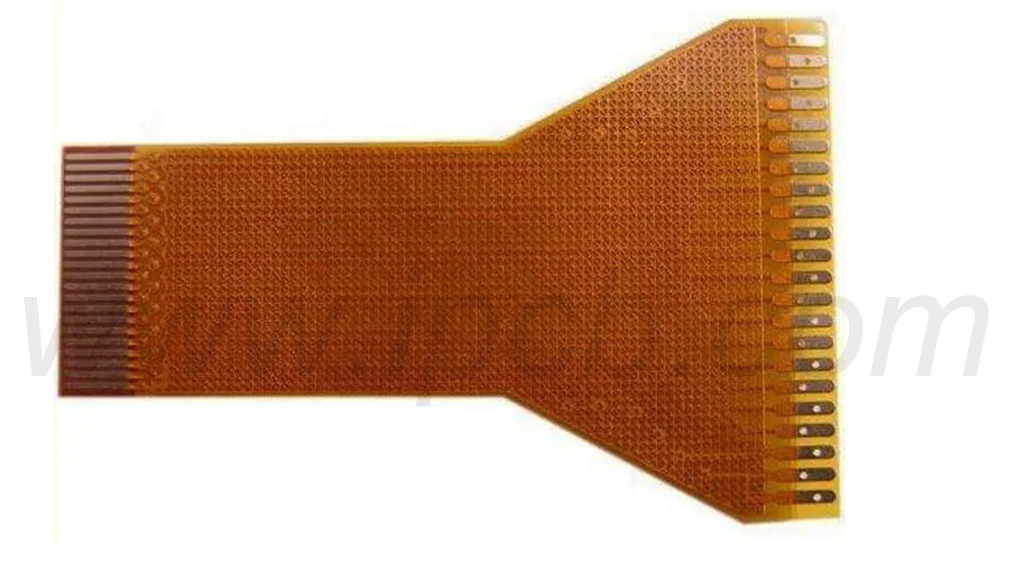

Material selection is a key factor in the performance of a flexible circuit board.Designers should prioritize the use of flexible materials such as polyimide (PI) or polyester (PET),which can not only withstand bending and twisting,but also have good electrical characteristics and thermal stability.The thickness and flexibility of the material should be adjusted appropriately according to the application requirements to optimize the flexibility of the board.

2.Layout planning

In the layout planning,you need to rationalize the circuit path and component location to reduce wiring complexity and avoid potential interference.Designers should leave enough space for subsequent movement or deformation to leave room,but also to ensure that the circuit board can be installed in the target device.

3.Connection Forms

Choosing the appropriate connection form helps to enhance the overall flexibility of the flexible circuit board.Solderless connections or flexible connectors are used to minimize seams and thus reduce the risk of potential contact failures.In addition,considering the possible bending and movement of the board,the connection points should be designed to avoid concentrating too much burden on a single location.

4.Adaptation of design rules

Designing flexible PCBs requires following certain design rules that may be different from those of rigid PCBs.For example,the wire spacing and wire width in a flexible PCB should be properly adjusted to accommodate bending and twisting.Designers also need to take into account the bending radius of the board to ensure that its integrity is maintained during use.

5.Testing and Verification

After the design is completed,adequate testing and verification is essential.This ensures that the board's flexibility and performance meets expectations under a variety of environmental conditions.By quantitatively testing the board under different conditions,the designer is able to identify potential design flaws and make improvements.

6.Focus on Cost and Benefit

When designing flexible circuit boards,there is also a need to balance the costs and benefits.While high-quality flexible materials and flexible design can enhance product performance,the initial investment and production costs also need to be carefully considered in order to achieve the best price/performance ratioWhere necessary,traditional rigid boards can be considered for specific applications to reduce overall design and manufacturing costs.

7.Flexible design for the future

With the continuous development of technology,the design of flexible circuit boards will gradually develop in the direction of intelligent and adaptive.Future designers may utilize advanced materials and intelligent algorithms to better respond to the changing needs of the market and achieve increased flexibility in circuit board design and manufacturing.

Flex on board plays a crucial role in modern electronic design.It not only enhances product adaptability and versatility,but also shortens development cycles and reduces production costs.As technology and materials continue to evolve,flexibility will continue to drive innovation in electronic products,providing more opportunities and challenges for designers.Future designs will focus more on intelligence and adaptability,helping companies stay competitive in a rapidly changing market.