Hard drive PCB board is one of the core components responsible for data storage and retrieval in hard disk drives (HDDs). It controls all electrical connections and data transmission within the hard drive, with its performance directly affecting the overall speed and reliability of the HDD. As the "brain" of the hard drive, the HDD PCB board not only ensures data integrity but also maintains stable operation in a complex circuit environment.

The Hard drive PCB board is a critical part of the hard disk drive. Its design and quality determine the basic functionality and overall performance of the hard drive. Serving as the "brain" of the drive, the HDD PCB board manages all electrical connections within the drive and ensures the safe transmission and reading of data. The performance of the HDD PCB board directly influences the read speed, stability of data transmission, and the overall reliability of the hard drive.The structure of the HDD PCB board includes several key components, such as the main controller chip, cache, firmware, and power management circuits. These parts work together to ensure that the hard drive can perform data read and write operations quickly and efficiently. To achieve this, the design of the HDD PCB board must consider numerous factors, such as circuit layout, material selection, and optimization of electrical characteristics.

In the manufacturing process of the hard drive, quality control of the HDD PCB board is crucial. Manufacturers must ensure that each PCB board can withstand the high-stress working environment of the hard drive, including heat resistance, electromagnetic interference resistance, and long-term stability. As modern hard drives continue to increase in capacity, the demands on the PCB board also grow. To meet these demands, manufacturers must use the most advanced manufacturing technologies and the highest quality materials.

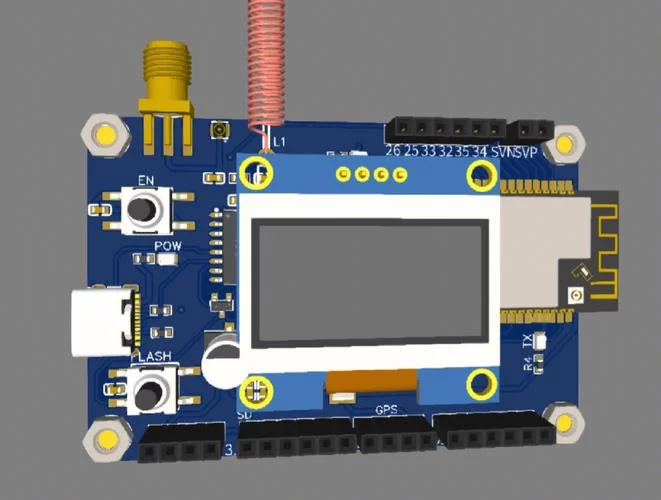

Hard drive PCB board

The design of the Hard drive PCB boardmust not only consider current technological requirements but also prepare for future developments. As data storage demands continue to grow, the capacity, speed, and reliability of hard drives are all improving, placing higher demands on the PCB board. To address these challenges, designers must continuously innovate, using the latest technologies and materials to improve the design and manufacturing processes of PCB boards.In the daily use of hard drives, the HDD PCB board needs to withstand frequent read and write operations. To ensure the long life and high reliability of the hard drive, the PCB board must have excellent electrical performance and stability. This requires considering all possible usage scenarios during the design process and strictly controlling every aspect of the manufacturing process to ensure the quality and performance of the PCB board.

The electrical performance of the HDD PCB board directly affects the read speed and data transmission stability of the hard drive. To improve the performance of the hard drive, manufacturers typically use advanced technologies in the design and manufacturing process, such as multilayer board technology, high-density interconnect technology, and surface mount technology. These technologies can effectively enhance the electrical performance of the PCB board, ensuring that the hard drive operates stably and reliably at high speeds.As technology continues to advance, the design and manufacturing of the HDD PCB board are also evolving. Modern hard drives are becoming larger in capacity and faster in speed, which increases the demands on the PCB board. To meet these demands, manufacturers must continuously innovate, using the latest technologies and materials to improve the design and manufacturing processes of PCB boards. In the future, as technology further develops, the HDD PCB board will play an even greater role in improving hard drive performance and reducing power consumption.

The Hard drive PCB board requires careful consideration of material selection and manufacturing process optimization during production. Due to the significant amount of heat generated during hard drive operation, the PCB board must have excellent thermal conductivity and heat resistance to prevent damage to the circuits. Additionally, the high-speed operation of the hard drive demands that the PCB board can withstand higher currents. Therefore, during the design and manufacturing process, it is crucial to ensure a reasonable layout of circuits and stable connections to enhance the overall performance and lifespan of the hard drive.As data storage demands continue to grow, the design of the HDD PCB board is constantly evolving. Modern hard drives increasingly aim for high density and small form factors, requiring the PCB board to achieve higher integration within limited space. To meet this demand, designers invest significant effort in material selection, circuit layout optimization, and the use of advanced manufacturing technologies. In the future, as technology advances, the HDD PCB board will play an even greater role in improving hard drive performance and reducing power consumption.

In conclusion, the Hard drive PCB board is a critical component of hard disk drives, influencing not only their basic functionality but also the overall performance and reliability of the HDD. With the continuous development of storage technology, the design and manufacturing of the HDD PCB board will continue to face new challenges, providing users with faster and more reliable data storage experiences.