Dielectric constant for Teflon PCB is a critical parameter that directly influences the signal transmission speed and quality of the circuit board. Teflon (PTFE), known for its excellent electrical performance and stability, is widely used in high-frequency and RF circuits. Understanding the DK for Teflon PCB is key to optimizing design and enhancing product performance.

Teflon is a fluoroplastic whose dielectric constant is usually expressed in terms of the relative dielectric constant, denoted as εr. With a dielectric constant ranging from 1.8 to 2.1, Teflon is a polymer material with excellent dielectric properties.

The Teflon dielectric constantcan be determined by measuring its capacitance. For this measurement, the electrodes of a capacitor are coated with a thin layer of Teflon and placed in a test circuit to measure the magnitude of its capacitance. Based on the magnitude of the capacitance and the size of the capacitor, the Teflon's dielectric constant can be calculated.

Dielectric constant for Teflon PCB is the primary factor engineers must consider in high-frequency applications,. Teflon's low dielectric constant enables faster signal propagation and lower loss across the circuit board. This is especially crucial for applications requiring high-precision and high-speed signal transmission, such as satellite communications, radar systems, and high-frequency amplifiers.The teflon dielectric constant not only affects the speed of signal transmission but also directly impacts signal integrity and overall system performance. Fluctuations in dielectric constant can lead to signal distortion, reflection, and other undesirable effects. Therefore, when designing high-frequency circuits, engineers must accurately calculate and control the dielectric constant of Teflon PCBs to ensure reliability and stability in real-world applications.

teflon dielectric constant

Dielectric constant for Teflon PCB also influences the choice of manufacturing processes in actual production. Due to the unique properties of Teflon, it poses certain challenges in processing, often requiring specialized equipment and techniques.Understanding and mastering the dielectric constant of Teflon can assist engineers in selecting the appropriate processing methods, ensuring product quality and consistency.As the complexity and demands of electronic circuits continue to grow, the importance of understanding the DK for teflonPCB becomes even more apparent.In the realm of high-frequency electronics,where every nanosecond counts,Teflon’s unique dielectric properties allow for the development of circuits that can operate at extremely high speeds with minimal signal loss.The teflon dielectric constant allows for the precise engineering of these circuits,ensuring that the signals maintain their integrity and that the devices perform at their highest potential.

In addition to signal speed and integrity, the teflon dielectric constant plays a significant role in impedance control. For high-frequency circuits, maintaining consistent impedance is crucial for minimizing reflections and ensuring signal fidelity. The low and stable dielectric constant of Teflon makes it an ideal material for achieving this consistency, particularly in environments where temperature variations could otherwise affect performance.

Moreover, Dielectric constant for Teflon PCB is critical in applications that require low power consumption. Because Teflon allows for efficient signal transmission, circuits built on Teflon PCBs can operate at lower power levels without sacrificing performance. This is particularly advantageous in the design of portable and wearable electronics, where power efficiency is paramount.As electronic devices become smaller and more powerful, the need for materials with low dielectric constants like Teflon will continue to rise. Engineers who understand the DK for teflonPCB will be better equipped to design the next generation of high-performance, energy-efficient electronic devices.In high-reliability applications, such as aerospace and defense,the DK for teflonPCB is even more critical.These applications demand materials that can withstand extreme conditions while maintaining their electrical properties.Teflon’s stability across a wide range of temperatures and frequencies makes it a preferred choice for PCBs in these sectors.Furthermore, as the industry moves towards higher frequencies, often in the millimeter-wave range,the DK for teflonPCB will become even more significant. At these frequencies, even small variations in dielectric constant can lead to significant performance issues.Therefore,precise control and understanding of the DK for teflonPCB are essential for the successful design and deployment of these advanced systems.

Teflon is widely used in electronic components and high frequency circuits because of its excellent dielectric properties. Teflon's thermal stability and corrosion resistance also make it a commonly used insulating material.

In RF microwave devices and antennas, the low dielectric constant and low loss angle tangent of Teflon materials enable them to maintain better signal transmission performance in the high frequency range.

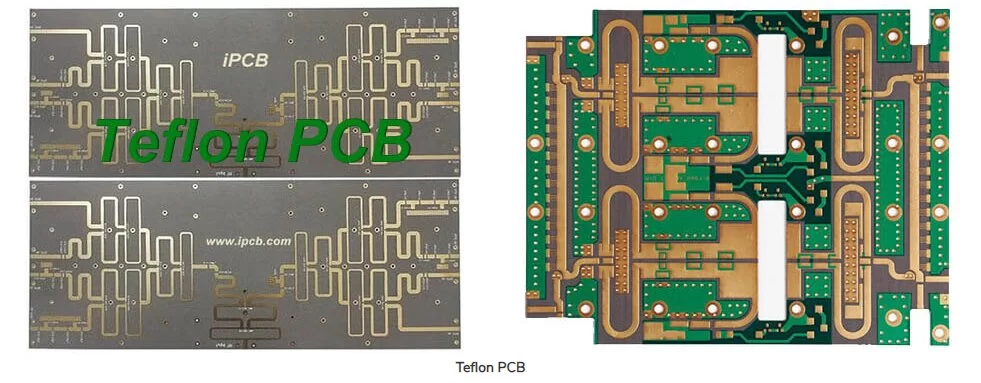

In printed circuit board (PCB) manufacturing, Teflon materials are used as cover and dielectric layers to ensure stable transmission of high frequency signals.

Teflon materials are also used in a wide range of applications such as medical devices, chemical instruments and aerospace to meet the need for high performance, high reliability and high temperature durability requirements.

In conclusion, the Dielectric constant for Teflon PCB is a fundamental consideration in the design and manufacture of high-frequency electronic circuits. Its impact on signal speed, integrity, impedance control, and power efficiency makes it a critical factor in the performance of modern electronic devices. As technology advances and the demands on electronic circuits increase, the importance of the teflon dielectric constant will only continue to grow. Engineers who master this aspect of PCB design will be at the forefront of innovation in the electronics industry.