Hot plate for SMD soldering has become an indispensable tool In modern electronics manufacturing. This soldering technique involves heating the PCB on a hot plate, causing the solder paste to melt and securely bond surface mount devices (SMDs) to the circuit board. This method is not only efficient but also ensures the quality and consistency of the solder joints.

Hot plate for SMD soldering operates by placing the PCB along with its components on a preheated hot plate. Typically made of aluminum or other highly conductive materials, the hot plate can rapidly and evenly heat the PCB. When the PCB reaches the melting point of the solder paste, the paste liquefies and forms strong bonds with the components. This process is precisely controlled, effectively reducing soldering defects.SMD welding heating plate offers several significant advantages. Firstly, it simplifies the SMD soldering process, making it particularly suitable for small batch and prototype production. Compared to traditional reflow ovens, hot plates provide greater flexibility and are easier to set up and clean. Secondly, hot plate soldering achieves precise temperature control, ensuring uniform quality across all solder joints. This is especially critical for high-reliability electronic products, such as medical devices and aerospace electronics.

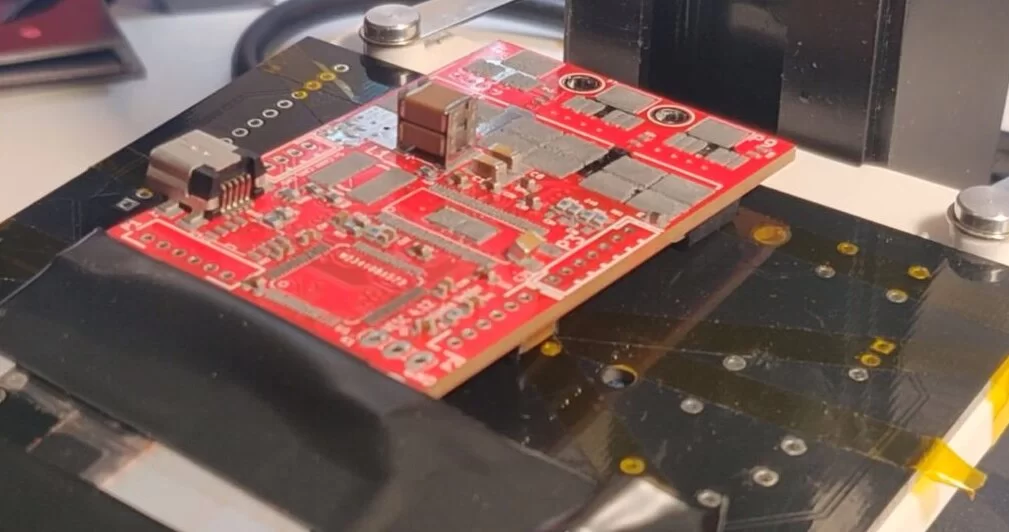

SMD welding heating plate excels in practical applications. It can handle various types of SMD components, including resistors, capacitors, and IC chips. Whether it's tiny 0201 package components or larger QFP and BGA packages, the hot plate can handle them all. Additionally, hot plate soldering is suitable for double-sided PCB production. By properly arranging the soldering sequence, both sides can be soldered using the same hot plate, significantly boosting production efficiency.

Hot plate for SMD soldering

Hot plate for SMD soldering also involves certain considerations in its design and usage. Firstly, selecting the right material and size for the hot plate is crucial. The material should have excellent thermal conductivity to ensure even temperature distribution, and the size should match the PCB dimensions for uniform heating. Secondly, temperature control is key. During heating, the temperature profile must be precisely controlled to avoid overheating or underheating, which could damage components and the PCB.In the production process, SMD welding heating plate maintenance is equally important. Frequent heating and cooling cycles can lead to oxidation or dirt buildup on the hot plate surface, affecting thermal conductivity. Therefore, regular cleaning of the hot plate surface to maintain its thermal performance is essential for ensuring soldering quality. Additionally, checking and calibrating the temperature control system to ensure it is functioning correctly is also a critical part of routine maintenance.

As electronics products continue to evolve, SMD welding heating plate technology is also advancing. For example, smart hot plate soldering systems have emerged, capable of automatically adjusting heating parameters based on the characteristics of different components and solder pastes, further improving soldering quality and efficiency. Moreover, the combined application of hot plate soldering with other soldering techniques, such as laser soldering and ultrasonic soldering, is being explored, promising more innovation and breakthroughs in the future.

Hot plate for SMD soldering is not just a tool but a technological breakthrough that continuously evolves to meet the growing demands of the electronics industry. Its role extends beyond simple heating; it involves integrating advanced control systems to achieve optimal performance. Modern hot plates come equipped with microprocessor-controlled temperature settings that ensure the exact heat required for different types of solder paste and components, minimizing thermal stress and potential damage.Moreover, the introduction of multi-zone hot plates has significantly enhanced the flexibility and efficiency of the soldering process. These hot plates can maintain different temperature zones simultaneously, allowing for a more tailored and precise soldering experience. This feature is particularly beneficial when dealing with complex PCBs that have components with varying thermal requirements.

The material composition of the hot plate also plays a crucial role in its effectiveness. Innovations in material science have led to the development of hot plates with superior thermal conductivity and stability. For instance, some high-end hot plates are made from ceramic composites that offer excellent heat retention and uniformity. These materials not only ensure even heating but also extend the lifespan of the hot plate by resisting wear and tear.

Hot plate for SMD soldering plays a vital role in PCB design and production. Through efficient and precise heating and soldering, hot plate technology provides a reliable solution for modern electronics manufacturing. Whether in small-scale laboratory production or large-scale industrial manufacturing, hot plate soldering technology demonstrates its unique advantages and vast application potential.