ECM PCB stator technology is an innovative motor design method that combines the advantages of electronically commutated motors (ECM) with printed circuit board (PCB) technology, offering a new level of performance and efficiency in modern motors. ECM motors have demonstrated excellent performance in various applications, and the introduction of PCB stators further optimizes the design and functionality of these motors.ECM print circuit board stator technology offers numerous significant advantages in motor design. Firstly, by integrating stator windings into the PCB, the size and weight of the motor can be significantly reduced. This not only makes the motor more compact and lightweight but also enhances its suitability in confined spaces. Additionally, PCB stators are highly designable and reproducible, allowing for customization according to specific application needs, ensuring optimal electrical performance and mechanical strength.

ECM PCB stator technology also excels in efficient thermal management. Traditional motors generate a significant amount of heat during operation, requiring complex cooling systems to maintain stable operating temperatures. However, due to its excellent thermal conductivity and large surface area, the PCB stator can dissipate heat more effectively, thereby improving motor efficiency and reliability. Furthermore, the structure of the PCB stator allows for more uniform heat distribution, preventing issues of localized overheating.ECM print circuit board stator technology demonstrates outstanding performance in the manufacturing process. The production of traditional motor stators involves complex coil winding and assembly processes, which are costly and intricate. In contrast, PCB stators can be mass-produced using automated production equipment, significantly reducing manufacturing costs and time. Additionally, the manufacturing process for PCB stators is more environmentally friendly, minimizing material waste and the emission of harmful substances.

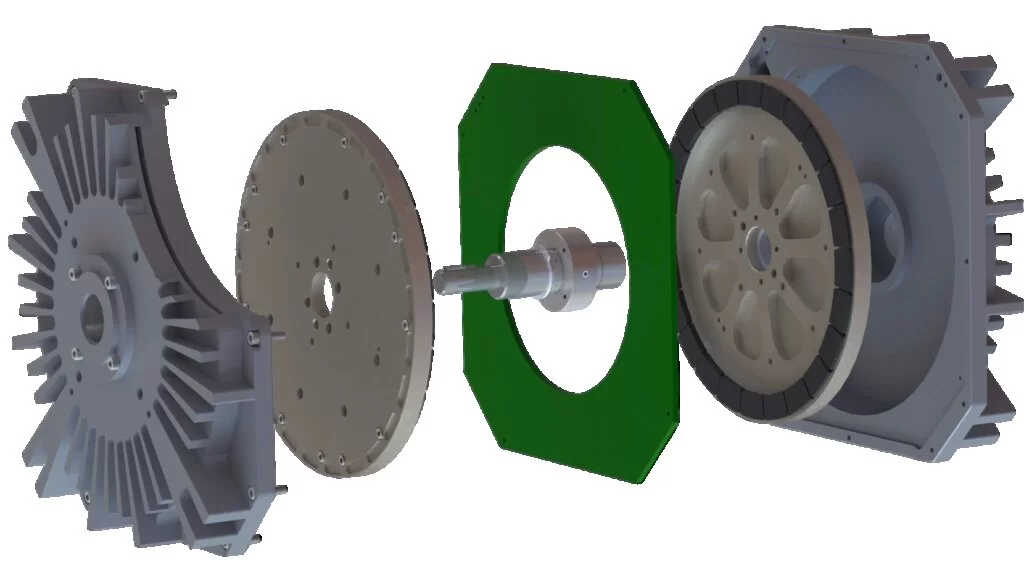

ECM PCB stator technology

In practical applications, ECM print circuit board stator technology has been widely adopted in household appliances, industrial automation equipment, automotive electronics, and medical devices. For instance, compressors in home air conditioners and refrigerators, servo motors in industrial robots, and drive motors in electric vehicles can achieve higher energy efficiency and longer service life through the use of ECM print circuit board stator technology. Moreover, in medical equipment, the precise control and low noise characteristics of PCB stator motors make them an ideal choice for high-end medical instruments.

ECM PCB stator technology in many areas have excellent performance, its design and application also face certain challenges. Firstly, the design of PCB stators requires a high level of engineering expertise and precise manufacturing processes to ensure stable operation under various complex conditions. Secondly, the material selection and process parameters of PCB stators need careful optimization to balance their electrical performance, mechanical strength, and cost. Furthermore, in some high-power applications, the heat dissipation capacity of PCB stators may become a limiting factor, necessitating further improvements and optimizations.Looking ahead, the technology is expected to play a crucial role in more fields. With continuous advancements in electronic technology and material science, the performance and reliability of PCB stators will be further enhanced, bringing more innovations and breakthroughs to motor design and manufacturing. Whether in improving energy efficiency, reducing carbon emissions, or promoting intelligent manufacturing and green technology development, ECM print circuit board stator technology will play an indispensable role.

ECM PCB stator technologyis not only transforming the current landscape of motor design but also paving the way for future innovations. One promising area of application is in renewable energy systems. For instance, wind turbines and solar panel tracking systems can greatly benefit from the compact and efficient designs of motors utilizing PCB stators. The ability to precisely control the movement and positioning of these systems enhances their overall efficiency and energy output.Moreover, ECM print circuit board stator technology is finding applications in the aerospace industry. Space-constrained and weight-sensitive environments like satellites and spacecraft require highly efficient and reliable motor systems. PCB stators offer the ideal solution with their lightweight, compact design, and high thermal efficiency. These characteristics are critical for ensuring the optimal performance and longevity of aerospace components.

ECM PCB stator technology represents a revolutionary advancement in modern motor design, changing our perception of motor performance and efficiency. By combining electronically commutated technology with advanced PCB manufacturing processes, ECM print circuit board stator technology offers more efficient, reliable, and economical solutions for various motor applications. As technology continues to evolve and applications expand, ECM print circuit board stator technology will play an increasingly important role in future motor design and manufacturing.