Curved PCB, also known as flexible printed circuit board, is a type of PCB that can bend and fold, gradually becoming a key innovation technology in electronic product design and production. Due to its unique design and flexibility, FPC is widely used in modern electronic devices, especially in wearable devices, smartphones, and medical equipment.FPC's most significant feature is its flexible material. Traditional PCBs are usually rigid, limiting design freedom. FPCs, made of flexible materials, can adapt to various complex three-dimensional shapes. This feature makes FPCs perform exceptionally well in space-constrained applications, such as wearable devices and portable electronics.

Curved PCB 's production process also differs from that of traditional PCBs. Due to its unique materials and structure, FPC manufacturing requires higher process precision and specialized production equipment. For example, the substrates of FPCs are typically made from high-performance flexible materials like polyimide, ensuring they do not break during bending and folding. Additionally, the welding and assembly of FPCs require special techniques to ensure components maintain good electrical connections when bent.In terms of design, FPC offers more possibilities. Designers can utilize the flexibility of FPCs in various innovative electronic products. For example, the curved screens and bent batteries of smartwatches are realized through FPCs. This design not only enhances the product's aesthetics but also improves user experience.

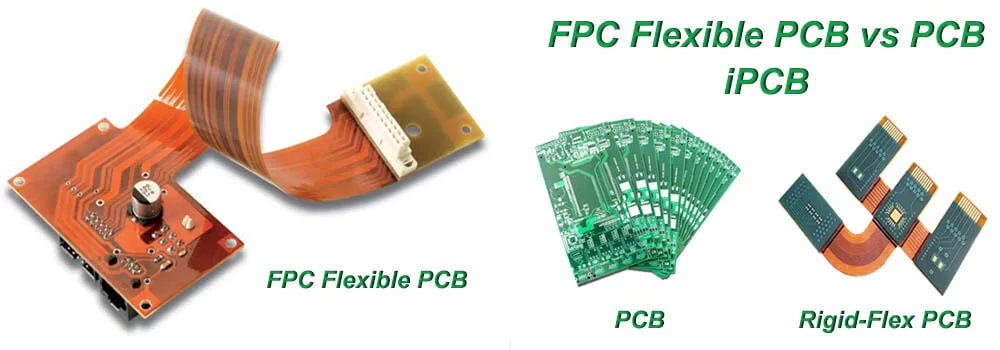

Curved PCB

Although FPC performs well in many applications, its design and manufacturing face some challenges. Firstly, the cost of FPCs is relatively high, mainly due to the complexity of materials and manufacturing processes. Secondly, FPCs might be affected by mechanical stress during use, leading to circuit damage. Therefore, these factors must be considered in the design and manufacture of FPCs to ensure their reliability and durability.

Curved PCB is also an important application area in medical equipment. Due to its flexibility and lightweight characteristics, FPCs can be used in various portable and implantable medical devices. For example, flexible electrocardiogram devices and implantable neural stimulators are realized through FPCs. These devices not only provide better diagnostic and therapeutic effects but also improve patient comfort and quality of life.In consumer electronics, the application of FPC is also increasingly widespread. For example, the curved screens and flexible batteries of smartphones are realized through FPCs. This design not only makes the product more beautiful but also improves its durability and portability. With continuous technological advancements, FPCs will demonstrate their unique advantages and application value in more fields.

One of the promising applications of FPCs is in the automotive industry. Modern vehicles are increasingly incorporating advanced electronic systems for safety, entertainment, and performance enhancement. The flexibility of FPCs allows them to be integrated into various parts of the vehicle, including dashboards, seats, and control panels. This integration facilitates the development of more sophisticated and ergonomic designs, contributing to the overall user experience.

Curved PCB technology is also paving the way for innovations in the field of Internet of Things (IoT). IoT devices often require compact, flexible, and durable circuit boards to fit into a wide range of environments and applications. FPCs can be designed to meet these requirements, enabling the creation of more efficient and versatile IoT devices. These boards can be integrated into smart home devices, wearable health monitors, and industrial sensors, enhancing their functionality and reliability.In the realm of robotics, FPCs offer significant advantages. Robots often require flexible circuits to accommodate their range of motion and complex movements. FPCs provide the necessary flexibility and durability, allowing robots to perform more intricate tasks with precision. This capability is particularly valuable in fields such as medical robotics, where precise and flexible movements are essential for procedures like surgery and rehabilitation.

Curved PCB is an innovative electronic component that is changing the design and production methods of electronic devices. By adopting flexible materials and advanced manufacturing processes, FPCs offer more possibilities for electronic product design. Despite facing some challenges, their unique advantages and broad application prospects make FPCs an essential part of future electronic devices. With continuous technological advancements, we can expect FPCs to be applied and developed in more fields, bringing more innovations and breakthroughs to electronic products.