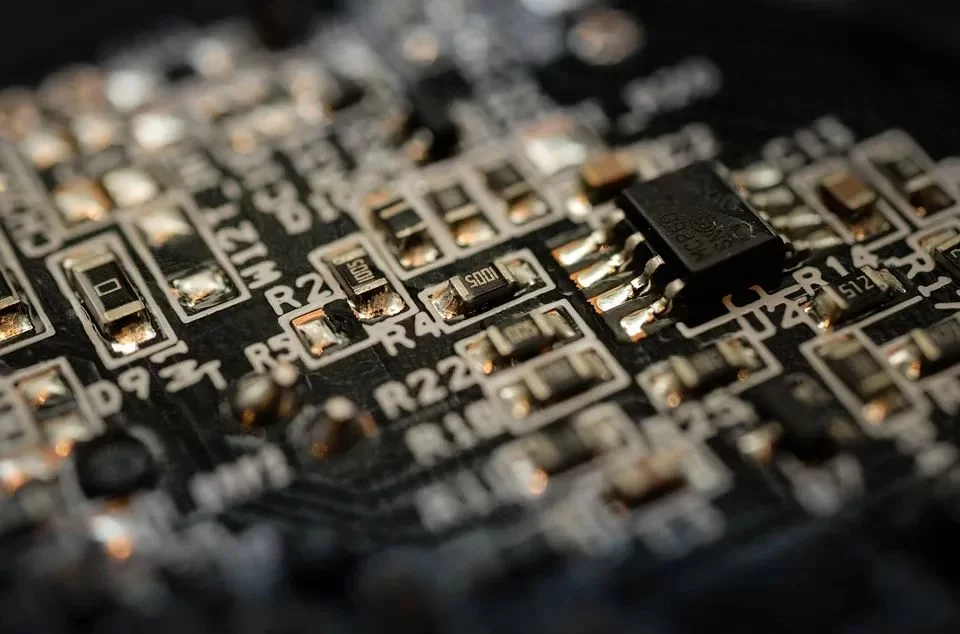

Broken circuits are a common and troublesome issue in PCB design and production. A broken circuit not only disrupts the normal operation of electronic devices but can also lead to severe equipment failure and financial losses. Therefore, understanding the causes of Non-functioning circuit and finding effective solutions is crucial for ensuring the quality and reliability of PCBs.

Non-functioning circuit often occur at various stages of the PCB manufacturing process. During fabrication, improper handling or the use of substandard materials can result in Non-functioning circuit. For instance, excessive mechanical stress, temperature fluctuations, and chemical corrosion can all cause the conductive traces on the circuit board to break. Additionally, during transportation and assembly, external forces can also lead to circuit breakage.

Broken circuits detection and repair are critical steps in PCB production. During the manufacturing process, methods such as visual inspection, X-ray inspection, and ultrasonic testing can help identify broken circuit issues early. Once detected, effective repair methods like using conductive adhesives or soldering can restore the electrical conductivity of the circuit. Simultaneously, preventive measures must be taken during the design and manufacturing stages to avoid circuit breakage.Non-functioning circuit prevention is a systematic endeavor. Firstly, during the design phase, it is essential to consider the working environment and usage conditions of the PCB, choose appropriate materials and processes, and optimize the circuit layout to reduce stress concentration points. Secondly, during manufacturing, it is crucial to strictly control the process parameters at each stage, ensuring standardized and consistent operations. Regular maintenance and upkeep of the production equipment are also necessary to prevent equipment malfunctions that could lead to circuit breakage.

Broken circuits

Broken circuits solutions rely heavily on advanced technologies and equipment. For instance, Automated Optical Inspection (AOI) systems can continuously monitor the quality of circuit boards on the production line, quickly identifying and addressing broken circuit issues. Moreover, the application of new materials and technologies, such as high-strength copper foil and flexible PCBs, can enhance the reliability of circuit boards and reduce the incidence of Non-functioning circuit.The role of soldering in Non-functioning circuit cannot be understated. Poor soldering techniques can lead to weak joints that are prone to breaking under stress. Implementing stringent soldering standards and utilizing advanced soldering technologies, such as reflow soldering and wave soldering, can ensure strong, reliable joints. Additionally, regular training for technicians on best soldering practices can help maintain high standards of workmanship, reducing the incidence of Non-functioning circuit.

Environmental factors also play a significant role in the occurrence of Non-functioning circuit. Humidity, temperature extremes, and exposure to corrosive substances can all contribute to circuit damage. Implementing protective measures, such as conformal coatings and encapsulation, can shield the PCB from these environmental hazards. Conformal coatings, in particular, provide a protective layer that can guard against moisture, dust, and chemical contaminants, extending the lifespan of the PCB and preventing circuit breakage.

Broken circuits can also be addressed through better design practices. For instance, incorporating redundant paths for critical signals can provide an alternative route if one path breaks, ensuring the device continues to function. Additionally, designing for manufacturability (DFM) principles can help identify potential issues early in the design process, making the PCB easier to produce without defects that could lead to Non-functioning circuit.Another crucial aspect of preventing Non-functioning circuit is the implementation of robust quality control measures. Regular inspections and testing at various stages of the manufacturing process can catch defects early, allowing for immediate corrective actions. Techniques like in-circuit testing (ICT) and functional testing can verify the integrity of the circuit and ensure that all connections are intact before the PCB is deployed.

In the era of smart manufacturing, the use of data analytics and machine learning is becoming increasingly important in addressing Non-functioning circuit. By collecting and analyzing data from the production process, manufacturers can identify patterns and root causes of circuit breakage. Machine learning algorithms can predict potential failures and suggest preventive measures, allowing for proactive maintenance and reducing downtime.

Addressing Broken circuits in PCB design and production requires a multifaceted approach. By leveraging advanced simulation tools, selecting high-quality materials, implementing robust soldering techniques, protecting against environmental factors, following best design practices, and utilizing smart manufacturing technologies, manufacturers can significantly reduce the occurrence of Non-functioning circuit. These efforts not only improve the reliability and performance of electronic devices but also enhance the overall efficiency and cost-effectiveness of the manufacturing process.