Battery PCB boards plays a crucial role in modern electronic devices. With technological advancements and growing market demands, the design and manufacturing techniques of Battery circuit board are continually evolving. These circuit boards not only provide stable power to devices but also ensure the safety and reliability of the equipment.

Battery PCB boards is characterized by high efficiency, stability, and safety. In designing Battery circuit board, engineers must consider factors such as battery voltage, current, and capacity to ensure that the battery operates normally under various conditions. Additionally, Battery circuit board must have good heat dissipation performance to prevent the battery from overheating, which can affect the lifespan of the device.

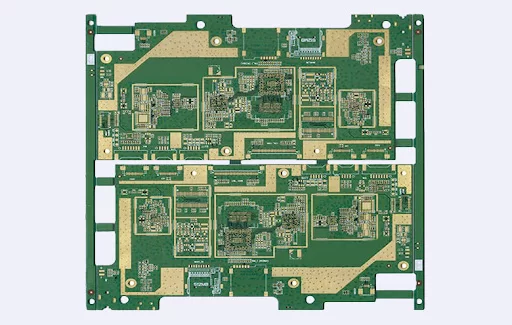

In the manufacturing of Battery circuit board, the choice of materials and processes is crucial. Common materials include FR4, aluminum substrates, and ceramic substrates. These materials have good thermal conductivity and electrical insulation properties, which can effectively enhance the performance and reliability of Battery circuit board. At the same time, advanced manufacturing processes such as multilayer technology, blind via technology, and precision etching technology are widely used in the production of Battery circuit board to achieve higher integration and smaller sizes.

Battery PCB boards

Battery PCB boards have a wide range of applications. From smartphones and laptops to electric vehicles and renewable energy systems, Battery circuit board are used in almost all battery-powered electronic devices. In these applications, Battery circuit board not only provide stable power but also include features such as overcurrent protection, overvoltage protection, and short circuit protection to ensure the safe operation of the equipment.

In the design and manufacturing of Battery circuit board, engineers face many challenges. For example, how to integrate more functions in limited space, how to increase the energy density and lifespan of the battery, and how to reduce manufacturing costs. To address these challenges, engineers continually explore new materials and technologies, such as high-efficiency energy conversion materials, advanced battery management systems, and intelligent manufacturing technologies.

A notable feature of battery circuit board is its efficient power management capability. During the design process, engineers need to pay special attention to the battery's charging and discharging characteristics to ensure the circuit board can supply stable power under different working conditions. This includes protection against overcharging, over-discharging, over-current, and short-circuits. Additionally, to extend battery life, Battery circuit board often come equipped with temperature sensors and other monitoring devices to keep track of the battery's status in real-time.

When producing Battery PCB boards, the choice of materials is crucial. Since the battery PCB board needs to charge and discharge frequently, the conductivity and durability of the board material are of utmost importance. Engineers usually select board materials with moderate copper foil thickness to ensure low resistance and high reliability of the circuit. Moreover, to address the heat generated by the battery, the design of the battery PCB board needs to incorporate good heat dissipation solutions. This can be achieved by adding heat dissipation holes, using high thermal conductivity materials, and other methods.

In practical applications, Battery circuit board are widely used in smartphones, tablets, laptops, wearable devices, and various portable electronic products. These devices have high requirements for power management, so the design of the battery PCB board directly affects the performance and user experience of the devices. For instance, in smartphones, the battery PCB board must not only provide stable power but also support fast charging and wireless charging functions. This places higher demands on the design of the battery PCB board, requiring continuous innovation and optimization.

The Battery PCB boards is an indispensable part of modern electronic devices. By continuously optimizing design and manufacturing processes, Battery circuit board can meet the demands for efficient and reliable power management and adapt to various complex application scenarios. In the future, with the ongoing development of electronic technology, the design and production of Battery circuit board will face more challenges and opportunities, requiring engineers to constantly explore and innovate to drive continuous progress in this field.