IC board Design is a crucial aspect of electronic engineering, determining the performance, reliability, and cost-effectiveness of electronic devices. This article will explore the key steps, design principles, and latest technology trends in IC PCB Design to help engineers achieve better results in this field.

IC PCB Design is the foundation of electronic device development, involving the arrangement of electronic components and connections on a printed circuit board (PCB). Good design can enhance system performance, reduce power consumption, shrink size, and improve manufacturing efficiency. Additionally, optimized IC PCB Design can reduce electromagnetic interference (EMI) and improve the system's anti-interference capabilities.

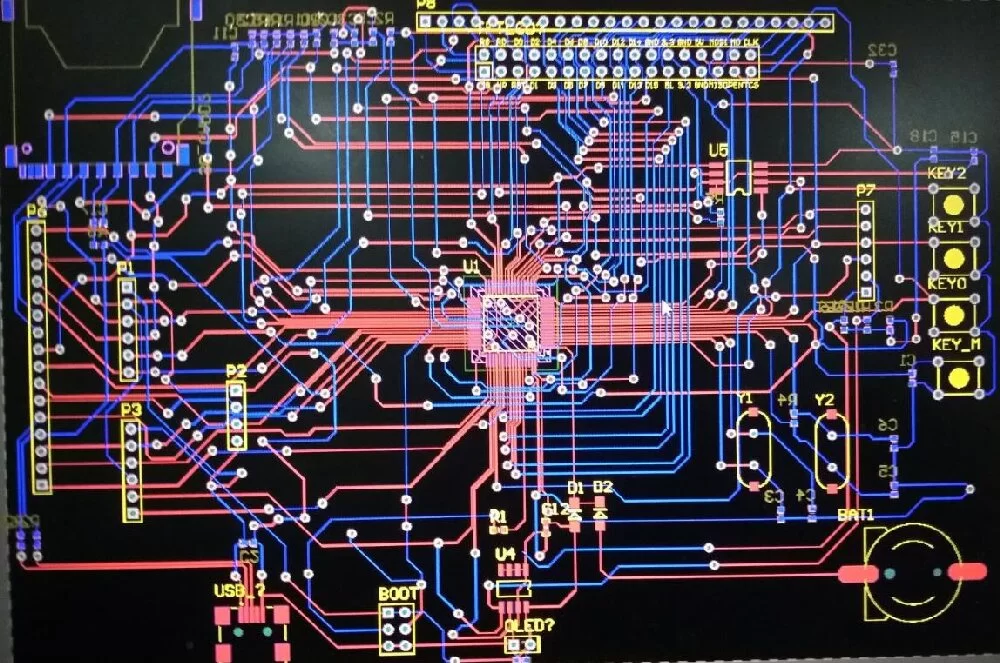

IC board Design

IC board Design Steps

1. Requirement Analysis: Before starting the design, engineers need to clarify the system's functional requirements, performance indicators, and physical constraints. This step includes selecting appropriate electronic components, determining the circuit topology, and defining the interfaces between various modules.

2. Schematic Design: At this stage, engineers use EDA (Electronic Design Automation) tools to draw the circuit schematic. These tools help engineers quickly generate circuit diagrams, perform simulations, and validate designs.

3. PCB Layout: Based on the schematic, engineers arrange electronic components and connections on the PCB. The layout design needs to consider the size, position, thermal requirements, and electrical characteristics of the components to ensure circuit performance and reliability.

4. Routing: Routing is one of the most critical steps in PCB design. Engineers need to route according to electrical rules and physical constraints, ensuring signal integrity and power stability.

5. Simulation and Verification: Use EDA tools to simulate and verify the design, ensuring the circuit meets the design requirements. Common simulations include electrical, thermal, and mechanical simulations.

6. Manufacturing and Testing: After the design is complete, generate manufacturing files and send them to the PCB manufacturer for production. After production, test the finished product to ensure it meets design specifications.

IC board Design Principles

1. Signal Integrity: Ensure signals do not distort during transmission, including controlling signal impedance, delay, and crosstalk.

2. Power Integrity: Ensure the stability of the power distribution network (PDN), reducing power noise and voltage fluctuations.

3. Thermal Management: Through proper layout and thermal design, ensure components maintain appropriate temperatures during operation to prevent performance degradation or damage.

4. Electromagnetic Compatibility (EMC): Consider electromagnetic compatibility in the design to reduce electromagnetic interference and improve the system's anti-interference capability.

5. Design for Manufacturability (DFM): Consider manufacturing process limitations during the design process to improve production efficiency and reduce production costs.

IC board Design Technology Trends

1. Multilayer PCBs: To meet the demand for high density and high performance, more designs use multilayer PCBs, improving signal transmission quality and power distribution stability.

2. HDI Technology: High-Density Interconnect (HDI) technology can significantly reduce the size of circuit boards and increase wiring density, suitable for mobile devices and high-performance computing.

3. Flexible PCBs: Flexible PCBs can be bent and folded, suitable for applications requiring high reliability and flexibility, such as wearable devices and medical equipment.

4. RF and High-Speed Circuit Design: With the development of 5G and high-speed communication technologies, RF and high-speed circuit design have become new hotspots. Engineers need to master more RF knowledge and high-speed signal processing technologies.

5. Evolution of EDA Tools: With the development of artificial intelligence and big data technologies, EDA tools have become more intelligent and automated, better assisting engineers in design and verification.

IC board Design is a complex and ever-evolving field. Engineers need to continuously learn and master new technologies to meet the increasing design requirements and market demands. By adopting reasonable design methods and advanced design tools, engineers can achieve better results in IC PCB Design, contributing to the development and innovation of electronic devices.