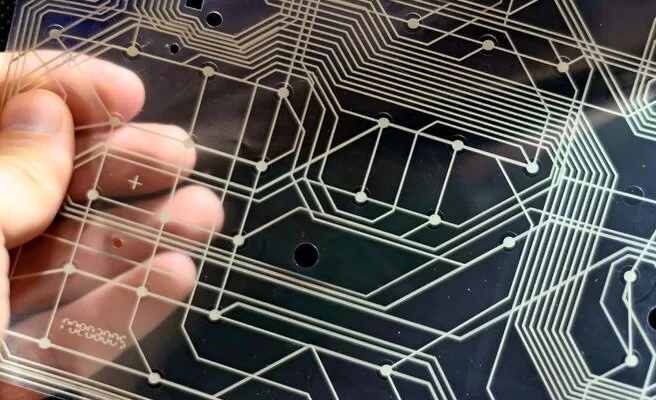

Transparent PCB board is an emerging technology trend in the field of printed circuit board (PCB) design and production. It not only enhances the aesthetic appeal of products but also offers numerous practical applications. What exactly is a transparent PCB board? A transparent PCB board, as the name implies, is a transparent circuit board. It is a type of flexible circuit board that utilizes PET film, which can be made transparent, pure white, light blue, light green, and other colors. PCB manufacturers can directly make it transparent, a process that is typically handled by flexible circuit board manufacturers and considered mature technology. FPC transparent boards are made using a material called transparent PET, and the manufacturing process is similar to that of flexible circuit boards.

Features of Transparent PCB Board:

1. They can be bent, folded, rolled, and moved and stretched freely in three-dimensional space.

2. They have excellent heat dissipation and can reduce the size using transparent FPC flexible circuit boards.

3. They achieve lightweight, miniaturization, and thinness, thereby integrating component installation and wiring, playing a pivotal role in electronic components.

4. FPC transparent boards are transparent circuit boards made from PET.

5. Film circuit boards are flexible circuit boards made from PET film as the substrate, with flexible FPC transparent circuit boards.

6. FPC transparent circuit boards are widely used in electronic mechanical automation control, instrumentation, medical devices, consumer electronics, computers, communications, measurement, household appliances, toys, and more.

Transparent PCB boards

When producing transparent printed circuit board, specialized manufacturing processes are required. Traditional PCB manufacturing processes, such as drilling, plating, and etching, may need to be adjusted to accommodate the characteristics of transparent materials. For instance, transparent materials may be more sensitive to high-temperature processes, necessitating finer temperature control during soldering. Additionally, to maintain transparency, transparent conductive materials like transparent conductive polymers or indium tin oxide (ITO) films may be used in place of traditional copper conductors.

Transparent PCB board have a wide range of applications in modern electronic devices. Due to their unique appearance, transparent printed circuit board are increasingly popular in consumer electronics, such as smartphones, wearables, and high-end home appliances. Transparent printed circuit board not only enhance product aesthetics but also make internal circuits visible, facilitating inspection and maintenance. Moreover, transparent printed circuit board play a significant role in optoelectronic applications like transparent displays and optical sensors. The high light transmittance and low reflectance of transparent materials improve the performance of these applications.

In designing and producing transparent PCB board, engineers face several technical challenges. The first challenge is material selection. The electrical and mechanical properties of transparent materials may not be as good as traditional materials, requiring a careful balance between performance and transparency. Additionally, the cost of transparent materials is usually higher, potentially increasing production costs. Therefore, designing transparent printed circuit board requires considering performance, cost, and aesthetics to achieve the best design solution.Another challenge is maintaining transparency during production. Since transparent printed circuit board use transparent conductive materials, these materials typically have higher resistance than traditional copper conductors. Engineers need to optimize circuit designs to reduce conductor length and width, mitigating the impact of higher resistance. Additionally, the sensitivity of transparent materials to environmental conditions like humidity and temperature must be carefully managed to ensure circuit reliability under various conditions.

In conclusion, transparent PCB board is an innovative technology with broad application prospects. Through thoughtful design and advanced manufacturing processes, transparent printed circuit board can provide reliable electrical and mechanical performance while enhancing product aesthetics. Engineers need to continuously explore and optimize the design and production techniques of transparent printed circuit board to meet the growing market demand.