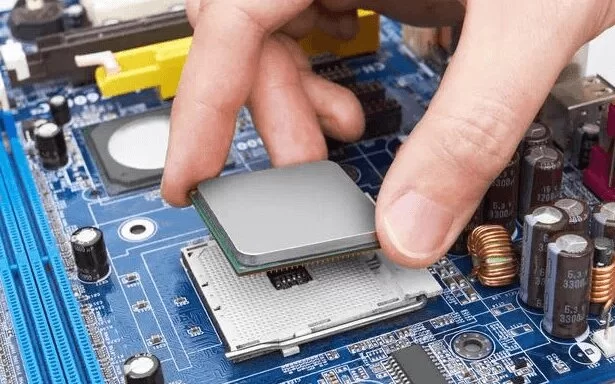

knowing how to remove an IC chip from a circuit board is a common and essential task in the process of repairing and modifying electronic devices. Whether replacing a damaged chip or upgrading the circuit board, this operation requires specific skills and tools. This article will detail the methods and steps on how to remove an IC chip from a PCB.First, we need to understand the basic principles of remove an IC chip from a PCB. IC chips are usually fixed on the circuit board through soldering, so heat is required to melt the solder joints to safely remove the chip. Common tools include soldering irons, heat guns, solder suckers, and soldering wicks. Choosing the right tools and methods can not only improve efficiency but also prevent damage to the circuit board and other components.

The first step in how to remove an IC chip from a circuit board is to heat the solder joints. Use a soldering iron or heat gun to heat the solder joints until the solder melts. When heating, maintain an appropriate temperature and time to avoid overheating and burning the circuit board. Generally, setting the heat gun temperature between 300 to 350 degrees Celsius is suitable.When the solder melts, use a solder sucker to remove the melted solder. This is a crucial step in remove an IC chip from a PCB The solder sucker can effectively clear the solder from the joints, separating the IC chip from the circuit board. When using the solder sucker, act quickly and steadily to ensure all solder is removed, avoiding residues.

how to remove an IC chip from a circuit board

The next step in how to remove an IC chip from a circuit board, gently lift the IC chip with tweezers. If the solder joints are handled properly, the chip should come off easily. If the chip is still difficult to remove, some solder joints may not be fully processed, requiring reheating and using the solder sucker again. During this process, be especially careful not to use too much force, which could damage the circuit board or chip.After successfully removing the IC chip, clean the circuit board. Use a soldering wick to remove any residual solder, ensuring the solder joints are clean and flat, ready for the new chip installation. Cleaning the solder joints is the final step in remove an IC chip from a PCB, and it is equally important. Clean solder joints not only ensure the stable installation of the new chip but also improve the overall performance and reliability of the circuit.By following the above steps, we can effectively master the technique of remove an IC chip from a PCB. Although this process requires some experience and patience, with the right methods and tools, the task can be smoothly completed. Whether an amateur enthusiast or a professional repair person, learning how to remove an IC chip from a circuit board is an important step in improving skills.

How to remove ic chip from circuit boardprecautions

1. Temperature control. You need to control the temperature during operation. Too high or too low will affect the soldering effect. If the temperature is too high, the chip or other circuit board components may be burned, while if the temperature is too low, the solder joints cannot be softened.

2. Prevent damage to the circuit board. You must be very careful when removing the chip to avoid damaging the circuit board or other components. You can use a clamp or similar tool to fix the circuit board on the table to prevent the circuit board from shaking.

3. Tool selection. Using the right tool can reduce the risk of damage. The suction mouth of the desoldering machine should match the size of the solder joint, and the soldering iron tip should be selected correctly to prevent damage to other circuit board components.

4. Safety measures. When using a soldering iron or other tools, pay attention to safety and avoid burns or other injuries. Gloves or other protective equipment can be used to improve safety.

In addition to the basic methods and tools, understanding some advanced techniques and tips can greatly enhance the efficiency and success rate. For example, when heating the solder joints, adding a small amount of solder to the joints can help conduct heat more quickly, making the solder easier to melt. Additionally, when using a solder sucker, you can use a soldering wick in conjunction, which can more thoroughly remove the solder from the joints, avoiding residue.

In summary, knowing how to remove an IC chip from a circuit board is a process that requires specific skills and experience, but with the right methods and tools, the task can be successfully completed. I hope this article helps you better understand this skill and improves the efficiency and success rate of repairing and modifying electronic devices.