Waterproof circuit boards play a crucial role in modern electronic devices. With the advancement of technology, electronic devices are increasingly exposed to humid and underwater environments. Therefore, ensuring the waterproof capability of circuit boards is not only to extend the service life of devices but also to ensure the safety and reliability of the equipment. In this article, we will discuss the importance, manufacturing processes, and application areas of waterproof PCBs.

Waterproof circuit boards are of paramount importance. Electronic devices are widely used in various environments, including household appliances, industrial equipment, automotive electronics, and outdoor devices. These devices may come into contact with water, moisture, and other liquids. If the circuit boards are not waterproof, it may lead to short circuits, corrosion, and other issues, affecting the normal operation of the equipment and even causing safety accidents. Therefore, adopting waterproof waterproof PCBs can effectively improve the durability and safety of devices.

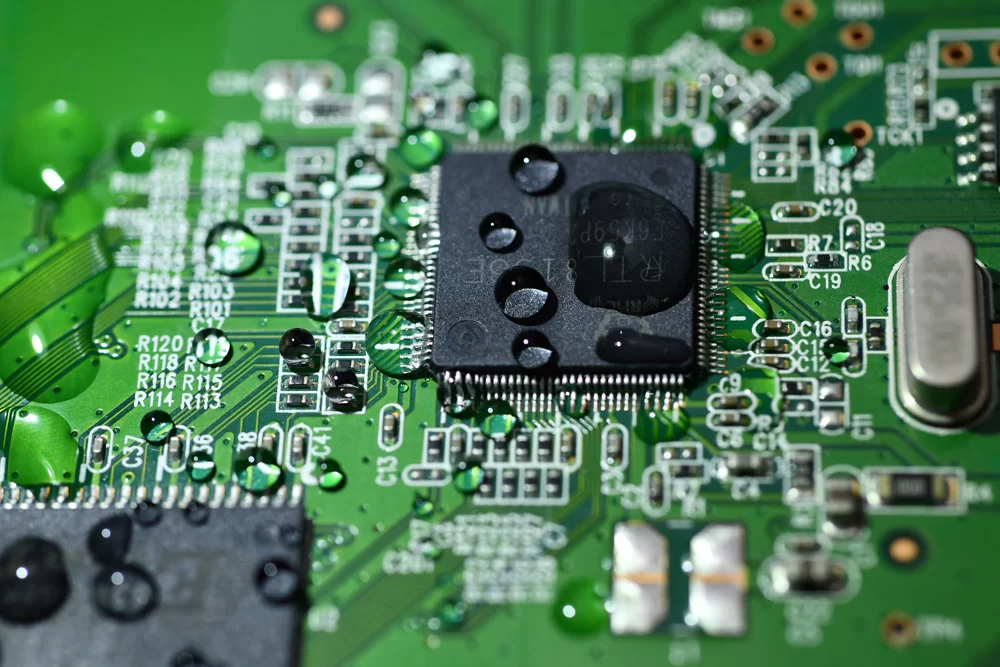

Waterproof circuit boards

The manufacturing processes of waterproof PCBs are diverse, mainly including surface coating, immersion, nano-coating, and waterproof material encapsulation. Firstly, surface coating is a common waterproof method, by coating a layer of waterproof material on the surface of the circuit board, which can effectively prevent moisture penetration. This method is cost-effective, simple, and suitable for mass production. Secondly, immersion is a more thorough waterproof method, by immersing the entire circuit board in a waterproof solution, ensuring that both the surface and interior are fully protected. Thirdly, nano-coating technology utilizes the unique properties of nanomaterials to form a dense protective film on the surface of the circuit board, which provides excellent waterproofing without affecting the electrical conductivity of the board. Lastly, waterproof material encapsulation involves encasing the entire circuit board in waterproof materials, providing comprehensive waterproof protection. This method is suitable for devices that need to operate in extreme environments.

Waterproof circuit boardshave a wide range of applications in various fields. Firstly, in the consumer electronics field, such as smartphones and smartwatches, these devices frequently come into contact with water and moisture. Waterproof waterproof PCBs can effectively prevent damage caused by water ingress. Secondly, in the automotive electronics field, modern vehicles are equipped with numerous electronic devices such as navigation systems, entertainment systems, and driver assistance systems, which need to function properly under various weather conditions, making waterproof PCBs crucial. Thirdly, in the industrial control field, many industrial devices need to operate in humid or underwater environments, such as oil drilling equipment and marine exploration devices. Waterproof PCBs ensure the long-term stable operation of these devices. Additionally, in the medical equipment field, many medical instruments require cleaning and sterilization, and waterproof PCBs ensure the safe use of these instruments.

The manufacture and application of waterproof PCBs face several challenges. The first challenge is the selection of waterproof materials. Different application environments require different performance characteristics from waterproof materials, so it is necessary to select suitable materials for specific applications. The second challenge is the optimization of waterproof processes. How to improve production efficiency and reduce costs while ensuring waterproof effectiveness is a problem that requires continuous exploration. Additionally, testing waterproof PCBs is a critical step. It is necessary to verify their waterproof performance and reliability through rigorous testing.

Waterproof circuit boards have broad development prospects. With continuous technological advancements, the emergence of new materials and processes will further improve the waterproof performance and reliability of circuit boards. Meanwhile, as the application areas of electronic devices continue to expand, the demand for waterproof PCBs will increase. For example, with the widespread adoption of IoT technology, more and more devices will be connected to the network, requiring reliable operation in various complex environments. Waterproof PCBs will be an essential guarantee for their reliable operation. Furthermore, as people demand higher living standards, more consumer electronic products will feature waterproof capabilities, expanding the market prospects for waterproof PCBs.

Waterproof circuit boards play a crucial role in modern electronic devices. Their manufacturing processes and application fields are diverse, with broad development prospects. Through continuous technological innovation and process optimization, waterproof PCBs will provide strong support for the reliability and safety of various electronic devices. In the future, waterproof PCBs will continue to play an important role in meeting the growing market demand.