Soldering wetting is a critical concept in electronics manufacturing and repair. It refers to the ability of molten solder to flow over and adhere to the surfaces being joined, creating a strong, conductive bond. This process is essential for ensuring the reliability and performance of electronic assemblies. Understanding the factors that influence and how to control them is crucial for producing high-quality solder joints.

Soldering wetting occurs when molten solder makes contact with a metal surface and spreads out to form a thin, uniform layer. This process involves several key factors, including surface tension, the cleanliness of the surfaces, and the properties of the solder alloy. The interaction between the solder and the base metal is influenced by the temperature, the presence of flux, and the duration of heating.

The primary goal of soldering is to create a metallurgical bond between the solder and the base metal. This bond is achieved through the dissolution of a small amount of the base metal into the solder, forming an intermetallic layer. Proper wetting is essential for this process, as it ensures that the solder can penetrate and adhere to the surface, resulting in a strong and reliable joint.

Soldering wetting

Factors Affecting Soldering Wetting

1. Surface Cleanliness: Contaminants such as oxides, oils, and dirt can significantly impair it. Cleaning the surfaces before soldering is essential to remove these contaminants and ensure good wetting. Methods such as chemical cleaning, mechanical abrasion, and the use of flux can be employed to achieve this.

2. Flux: Flux is a chemical agent that promotes wetting by removing oxides and preventing their reformation during the soldering process. It also reduces the surface tension of the molten solder, allowing it to flow more easily over the surfaces. Selecting the appropriate flux for the specific soldering application is crucial for achieving optimal wetting.

3. Solder Alloy: Different solder alloys have varying wetting characteristics. The choice of solder alloy can impact the ease of wetting and the strength of the resulting joint. Common solder alloys include tin-lead (Sn-Pb), tin-silver-copper (SAC), and lead-free formulations. Each of these alloys has distinct properties that affect wetting behavior.

4. Temperature: The soldering temperature plays a critical role in wetting. The solder must reach its melting point and remain molten long enough to wet the surfaces effectively. However, excessive heat can cause damage to the components and the base materials. Controlling the temperature within an optimal range is essential for achieving good wetting.

5. Time: The duration of heating also affects it. Sufficient time must be allowed for the solder to flow and form a bond with the base metal. However, prolonged heating can lead to issues such as thermal damage and excessive intermetallic growth. Balancing the heating time is crucial for optimal wetting.

Common Issues with Soldering Wetting

1. Non-Wetting: This occurs when the solder does not spread over the surface, resulting in poor adhesion and weak joints. Non-wetting can be caused by surface contamination, inadequate flux, or insufficient heating.

2. Dewetting: Dewetting happens when the solder initially wets the surface but then retracts, leaving behind exposed areas. This issue can be caused by the presence of contaminants, excessive heat, or incompatible solder alloys.

3. Cold Joints: Cold joints occur when the solder does not properly wet the surfaces, resulting in a dull, granular appearance. These joints are mechanically weak and can cause electrical failures. Insufficient heating or inadequate flux application are common causes of cold joints.

4. Bridging: Bridging occurs when solder inadvertently connects adjacent conductors, creating a short circuit. This issue is often due to excessive solder application or improper soldering techniques. Controlling the amount of solder and using appropriate soldering methods can help prevent bridging.

Advanced Soldering Techniques

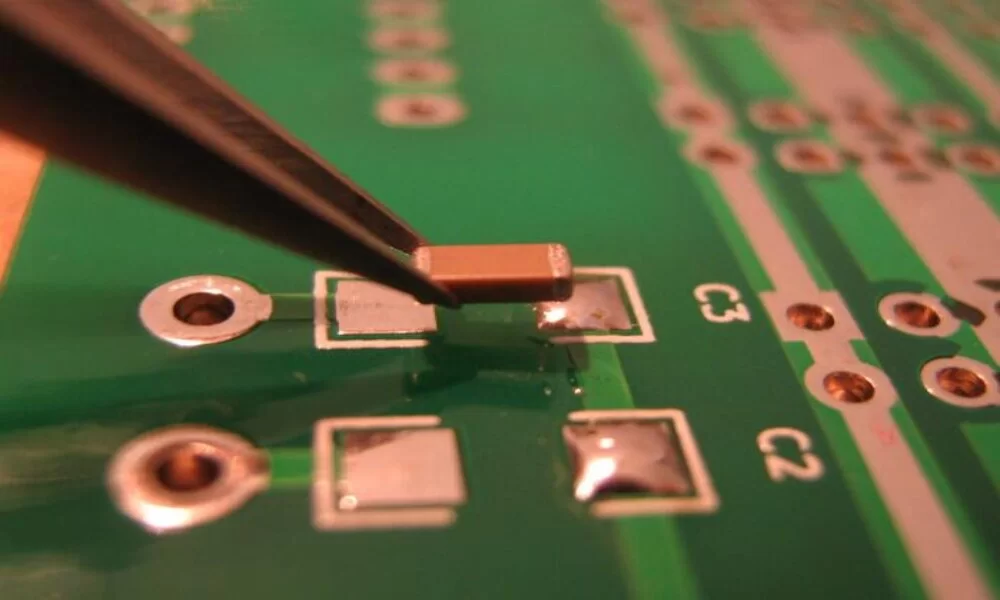

1. Reflow Soldering: Reflow soldering is a widely used technique for soldering surface mount devices (SMDs). The process involves applying solder paste to the PCB, placing the components, and then heating the assembly in a reflow oven. The controlled heating profile ensures proper wetting and the formation of strong solder joints.

2. Wave Soldering: Wave soldering is commonly used for soldering through-hole components. The PCB is passed over a wave of molten solder, which wets the exposed pads and leads, forming solder joints. Proper flux application and temperature control are crucial for achieving good wetting in wave soldering.

3. Selective Soldering: Selective soldering is used for soldering specific components or areas on a PCB. The process involves using a precise heating source to apply solder to the desired locations. This technique is useful for assemblies with mixed technologies or sensitive components that require localized soldering.

Soldering wetting is a fundamental aspect of the soldering process that significantly impacts the quality and reliability of electronic assemblies. Understanding the factors that influence wetting and employing techniques to control these factors are essential for achieving strong, conductive solder joints. By addressing issues such as surface cleanliness, flux application, solder alloy selection, temperature control, and heating time, manufacturers can ensure optimal wetting and produce high-quality solder joints. Whether using traditional soldering methods or advanced techniques like reflow, wave, and selective soldering, maintaining good wetting is key to the success of electronic manufacturing and repair.