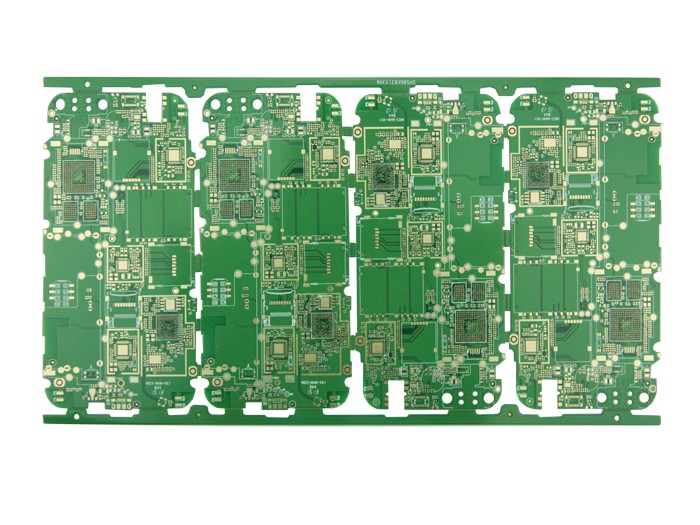

It can be seen that the multi-layer board is an inevitable product of the development of electronic technology in the direction of high speed, multi-function, large capacity, low power consumption, and easy movement. With the development of computer motherboards and graphics cards in the direction of high frequency, high integration, and miniaturization, the application of multi-layer PCB boards in the IT field is becoming more and more popular. Compared with single and double panels, multi-layer boards have the following four advantages:

The GeForce 6800 Standard Edition uses a 10-layer P212 form factor

1. From the perspective of PCB design, multi-layer boards provide PCB designers with more wiring space and play space: multi-layer boards shorten the wiring path, thereby increasing signal transmission speed; multi-layer boards make the signal ideal The reference layer and the space between wiring, thereby improving the impedance characteristics, high-frequency characteristics and signal integrity of the signal; the multi-layer board enables the power layer to be reasonably and effectively distributed on the PCB layer, the current transmission is smooth, and the power plane is stable.

2. From the EMC point of view, the multi-layer board design is flexible, and the interference source generated by EMC can be controlled from the source, and the interference path of EMC can be cut off. There is also enough space for the interfered source to protect and shield. In addition, the multi-layer PCB design can easily retain copper foil anywhere in different layers. These grounded copper foils can eliminate the electrical coupling between key circuits and minimize interference noise and signal crosstalk.

3. From a thermal point of view, multilayer boards can optimize the layout design of components by increasing their heat dissipation area for high-power devices, thereby optimizing heat transfer and improving the stability of the board.

4. Multilayer boards also increase confidentiality. PCB designers can design all important circuits to the inner layer according to their needs, making it difficult for other competitors to damage or affect their connection relationship, and ultimately improve the life of advanced electronic products.

The progress of the manufacturing process puts forward higher requirements for the PCB. Multi-layer boards have increased the difficulty of the processing and production process due to the relationship between the density and the number of layers, and the test is more difficult. The degree of reliability assurance is lower than that of single and double panels. Therefore, the production cost is relatively high. With the development trend of high-density circuit boards, the production requirements of circuit boards are getting higher and higher, and more and more new technologies are applied to the production of circuit boards, such as laser technology, photosensitive resin and so on. The development of all these technologies will make the design and production of PCB board more suitable for the development of IT technology and the needs of social development; the quality of PCB will increasingly determine the quality and life of the product.