Two ways to distinguish the quality of circuit boards

In recent years, almost one person has more than one electronic device. The electronics industry has developed rapidly, and it has also promoted the rapid rise of the PCB circuit board industry. In recent years, people have higher and higher performance requirements for electronic products, which has also led to higher and higher requirements for the quality of circuit boards. How to distinguish the quality of PCB circuit boards has also become a topic of increasing concern. Today, I will introduce two ways to distinguish the quality of circuit boards.

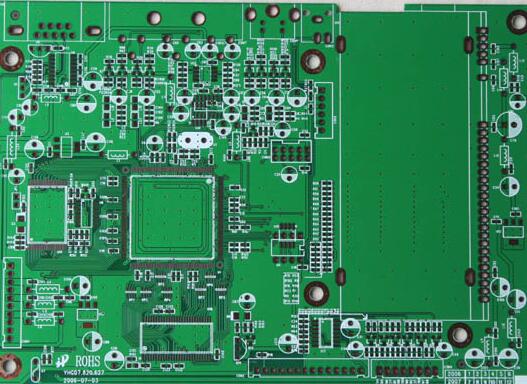

The first method is visual inspection, which is mainly to check the appearance of the circuit board. The most basic way to check the appearance is to check whether the thickness and size of the board meet the thickness and specifications you need. If it does not, you need to re-make it. In addition, with the fierce competition in the PCB market, various costs continue to rise. In order to reduce costs, some manufacturers continue to reduce material costs and production costs. Ordinary HB, cem-1, and cem-3 boards have poor performance and are easy to deform, and can only be used for single-sided production, while fr-4 fiberglass boards are much better in strength and performance. They are often used in double-sided and multi-sided boards. The production of laminates. Boards made of low-grade boards often have cracks and scratches, which seriously affect the performance of the board. This is also a place that needs to be paid attention to when visually inspecting. In addition, whether the solder mask is covered by the ink is smooth, whether there is copper exposed; whether the character silk screen is offset, and whether the pad is on or not also need to be paid attention to.

After the second method needs to be used, it comes out through performance feedback. First of all, it can be used normally after the components are installed. This requires that the circuit board is not short-circuited or open. The factory has an electrical test process during production to detect whether the board has an open or short circuit. However, some board manufacturers are saving The cost is not tested by electricity, so when proofing the circuit board, you must ask this point clearly. Then check the circuit board for heat generation during use, which relates to whether the line width/line spacing of the circuit on the board is reasonable. When soldering the patch, it is necessary to check whether the pad has fallen off under high temperature conditions, which makes it impossible to solder. In addition, the high temperature resistance of the board is also very important. An important index of the board is the TG value. When making the plate, the engineer needs to instruct the board factory to use the corresponding board according to different usage conditions. Finally, the length of time the board can be used normally is also an important indicator to measure the quality of a board.

When we buy circuit boards, we can't just start from the price. We should also consider the quality of the circuit boards and consider all aspects before we can buy cost-effective circuit boards.