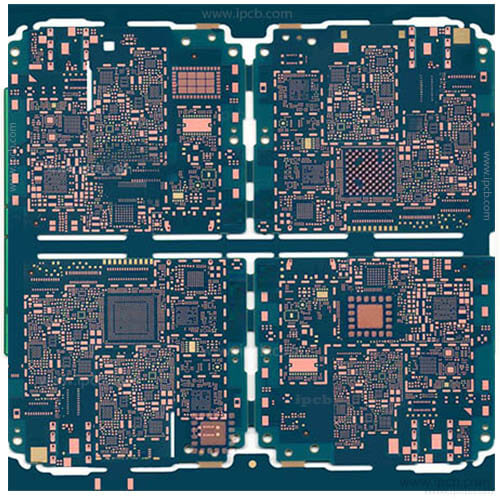

The printed circuit board (PCB) is made of glass fiber, reinforced resin and a variety of metal compounds. If the waste circuit board is not properly disposed of, the brominated flame retardant and other carcinogens contained in it will affect the environment and human health. Produce serious pollution and harm, but at the same time, waste circuit boards also have a high economic value. The metal grade in the circuit board is equivalent to dozens of times the metal grade in ordinary minerals, and the metal content is as high as 10% to 60%, while the rich mineral metal content in nature is only 3% to 5%. This shows that waste circuit boards are also a "gold mine" to be developed.

This technology better solves the problem of the comprehensive application of non-metallic powder in the recycling of waste PCB boards, creating a complete "green recycling industry chain". This treatment technology innovatively realizes the direct material utilization of non-metallic powders, truly achieves zero emissions, zero pollution, and has low treatment costs, which can obtain greater value from non-metal recycling.

Main technical difficulties and solutions

In the process of development and industrialization of the physical recycling and comprehensive utilization technology of waste printed circuit boards, there are the following main technical difficulties:

1. The separation degree of metal and non-metal and metal recovery rate index

According to the physical characteristics of metals and non-metals, we adopt the principle of pulverization combining shearing, impact and jet pulverization, and combine the pulverization with gravity sorting and wind classification to assemble a kind of crushing and separating equipment for circuit boards. Control of parameters such as wind pressure and air volume can almost completely separate metals from non-metals, with a separation rate of over 96%.

2. Dust and odor control

When developing recycling equipment for used circuit boards, the control of dust and odor during the production of circuit boards must be taken into consideration, and the environmental protection standards set by the country must be met.

In addition, in the process of breaking and crushing circuit boards, as the temperature rises and materials such as resin, glass fiber and plastics are destroyed and decomposed, a certain odor will be generated. If not processed in time, it will cause damage to the production environment and atmosphere. Cause a certain amount of pollution.

3. Purity of metal powder

The metal powder coming out of the metal discharge port of the crushing and separating equipment generally has a purity of only 60%-70%. The company adopts a combined selection process to increase the purity of copper from 60% to more than 90%. Up to 99%, the produced metal copper powder can be directly used in other fields, such as the production of fireworks and salutes.

4. Wear of crushing tools

Due to the special structure of the circuit board, which contains not only metal but also a variety of non-metallic composite materials, to crush it to a certain particle size, the wear of its tools is quite serious. If you use general tool steel or alloy steel, it will not only be resistant to Poor grindability and short service life will also affect equipment productivity and maintenance and manufacturing costs, and ultimately increase production costs.

5. Control of metal content in non-metal powder and materialized application of powder

The copper content in the non-metallic powder output from the discharge port of the cyclone collector and the dust removal equipment can be controlled below 1%, which is greatly beneficial to the application of non-metallic powder. Since we use a complete dry process to process circuit boards, the particle size distribution of the non-metallic powder after separation is more suitable for use as various fillers. We have successfully applied it to the production of wood-plastic profiles, outdoor landscape materials, sewer pipes, logistics pallets and other products after surface activation and modification treatment on non-metallic powders.