FPC pcb, also known as flexible circuit boards, are circuit boards manufactured from flexible copper-clad laminates and insulating layers. Its main features include light weight, thin thickness, bending and folding, allowing for higher integration and more compact structural design. This feature makes it widely used in various electronic products such as smartphones, tablet PCs, medical devices, etc., to meet the growing demand for small size and light weight of modern electronic devices.

Classification of FPC

1. Single-sided FPC

Single-sided FPCs are fpc pcb with one layer of conductive circuitry with conductive graphics that may be chemically etched. This type of circuit board is usually made of polyimide or polyester film and may or may not have an overlay on the surface. This type of structure is simple and is widely used in electronic products with low wiring requirements.

2.Double-sided FPC

Double-sided FPC has conductive graphics on both sides, which can significantly increase the wiring density, in line with the demand for high-density connections in modern electronic products. The wires are connected through metallized holes for efficient transmission of electrical signals, and a cover film protects the wires and identifies the placement of components.

3.Multilayer FPC

Multilayer FPCs are complex circuit boards consisting of three or more layers of circuit boards stacked on top of each other, with drilling and plating techniques used to form conductive pathways. This structure allows a high level of integration in a small space and is suitable for demanding electronic devices. The advantage is that it reduces signal interference and has good electrical characteristics.

4. Rigid-flex FPC

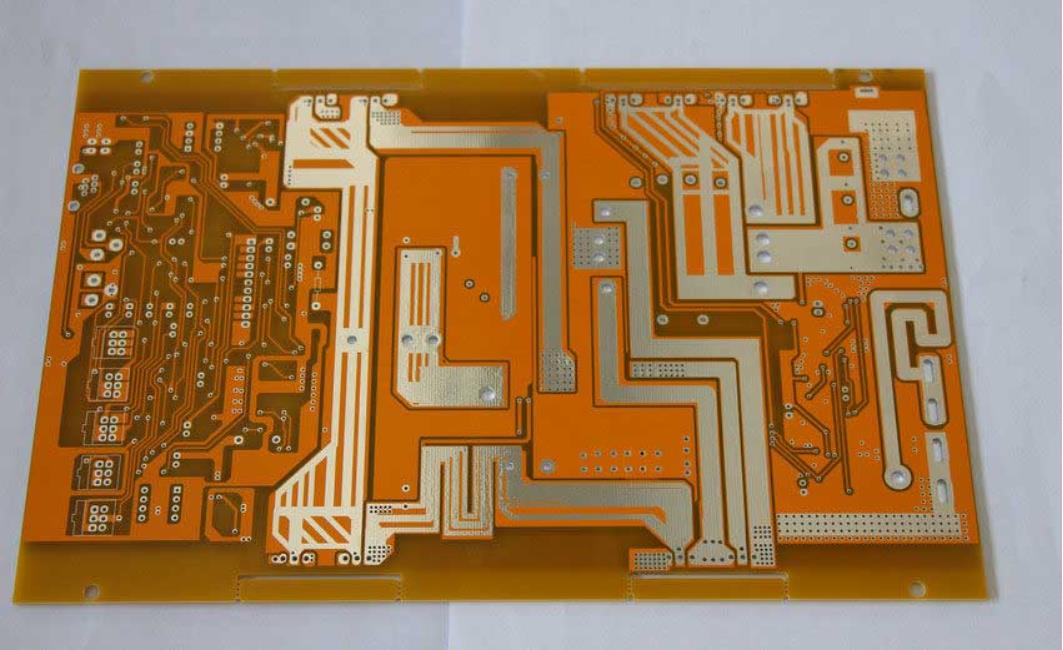

Rigid-flexible FPC is a combination of flexible circuit boards and rigid circuit boards combined circuit boards, forming a composite structure that has both the flexible characteristics of FPC and the rigid characteristics of PCB. This design effectively utilizes space and is suitable for products with special requirements for circuit boards.

5.Skeletonized boards

Skeleton boards, also known as window boards, are usually windows in specific areas to allow the connection of other components or circuits. They offer more possibilities for design flexibility and are suitable for products that require a specific shape or have special requirements for space utilization.

6.Layered boards

A layered FPC is a multilayer flexible circuit board that is bonded together but not synchronously bonded in the center, still maintaining a high degree of flexibility. This design allows for increased mechanical strength while maintaining circuit flexibility. This type is often used in complex circuit connections that require frequent movement.

Superior characteristics of FPC flexible circuit boards

First, excellent flexibility. Compared with traditional rigid PCBs (Rigid PCBs), FPC makes good use of flexible substrates and can be bent and folded without damaging the circuitry. This feature makes it adaptable to a variety of complex assembly environments, such as curved displays and curved devices. In addition, 3D assembly is supported, providing greater flexibility in product design.

Second, it has a higher circuit density and smaller size. Due to the use of thin-film substrates and miniaturized assembly technology, it can achieve more circuit connections in a limited space. In contrast, traditional rigid circuit boards are difficult to meet high density requirements due to size and thickness limitations. The FPC flexible circuit board can achieve a smaller volume and higher integration, helping products to achieve miniaturization and lightweight design.

Third, with excellent anti-vibration and shock resistance.Traditional rigid circuit boards in the face of vibration or shock can easily lead to breakage or solder joints off, while the FPC flexible circuit board can effectively adapt to vibration and shock environment. The flexible substrate and the conductive layer of the special bonding technology to ensure a high bond strength and durability. Therefore, FPC flexible circuit boards are particularly suitable for frequent movement or vulnerable to vibration impact equipment, such as cell phones, video cameras and game consoles.

In addition, it has superior resistance to high temperatures and corrosion. Its flexible substrate usually use special high-temperature adhesive or polyimide film, can be at higher temperatures to maintain stable performance. As a result, FPC flexible circuit boards can operate reliably in high-temperature environments, such as automotive engine rooms and heat-sensitive devices. At the same time, the conductive layer of FPC has been specially treated to show good corrosion resistance, suitable for long-term use in humid and corrosive environments.

Finally, good reliability and stability. Thanks to the high-precision production process and strict quality control,FPC circuit connection is very reliable, to avoid the occurrence of open circuit and short circuit and other problems. At the same time, it also has good anti-electromagnetic interference and static electricity ability to ensure the normal operation of electronic equipment.

In the future,FPC will continue to develop in the direction of high integration,high reliability and intelligence. The continuous research and development of new materials and processes will promote the deepening of FPC applications,especially in the fields of 5G,smart medical and wearable devices. At the same time, with the improvement of the industrial chain and the strengthening of international cooperation,the FPC industry will also provide a richer range of solutions to meet the increasingly diversified market demand!