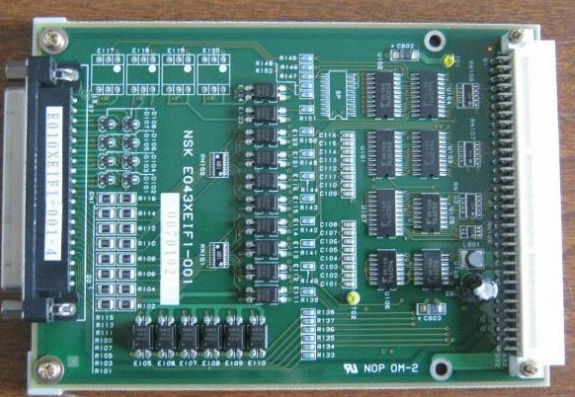

The following is an introduction to the copy board of the motor protector PCB circuit board:

The function of the motor protector is to fully protect the motor. It will give an alarm when the motor is overloaded, lack of phase, locked rotor, short circuit, overvoltage, undervoltage, leakage, three-phase imbalance, overheating, bearing wear, and stator and rotor eccentricity. Or protective device.

Motor protector: intelligent protection unit, motor intelligent protector, three-phase motor protector, motor overcurrent protector, motor integrated protector, motor thermal protector, motor protector, microcomputer protector, low voltage protector.

Motor protection module function introduction

Conforms to DIN 44081/082 standard, with different sensing temperatures, up to 9 PTC sensors, which can be connected to the input of the test circuit, so as long as one INT69 motor protector, you can monitor the control of one or more motor drive devices Temperature overheating (such as motor rotation, engine drive, bearing measurement).

If the temperature of a monitored area exceeds the normal reaction temperature of the respective PTC sensor, the resistance of the sensor increases, and the INT69 motor protector closes the motor contactor. When the temperature drops to about 3K below the specified temperature, the module restarts. The output relay provides a switchable connection without voltage, and at the same time as long as the temperature does not exceed the normal temperature, it will provide energy, so that it has a self-monitoring function. Because this device also acts on the PTC, or guides to open the loop.

Common types of motor protectors:

1. Thermal relay: Ordinary small-capacity AC motor, with good working conditions, no occasions such as severe working conditions such as frequent starting; due to poor accuracy and reliability cannot be guaranteed, it is not recommended.

2. Electronic type: detect the three-phase current value, use a potentiometer or a code switch to set the current value, the circuit generally adopts an analog type, and adopts inverse time or definite working characteristics. The protection function includes overload, lack of phase, locked rotor, etc. The fault type is displayed by indicator light, and the operating power is displayed by digital tube.

3. Intelligent type: it detects the three-phase current value, and the protector uses a single-chip microcomputer to realize the intelligent comprehensive protection of the motor, integrating protection, measurement, communication and display. The setting current adopts digital setting, which can be operated by buttons on the operation panel. The user can modify and set various parameters on the spot according to the specific conditions of the motor; adopt the digital tube as the display window, or adopt the large-screen LCD display, which can support a variety of communication protocols., Such as ModBUS, ProfiBUS, etc., are relatively expensive and are used in more important occasions; at present, high-voltage motor protection uses intelligent protection devices.

4. Thermal protection type: The thermal element is embedded in the motor, and the protection effect is good according to the temperature of the motor winding; but when the motor capacity is large, it needs to be used in conjunction with the current monitoring type to prevent the temperature from rising sharply when the motor is locked., Due to the hysteresis of the temperature measuring element, the motor winding is damaged.

5. Magnetic field temperature detection type: The magnetic field detection coil and temperature measuring element are embedded in the motor, and the protection is performed according to the change of the internal rotating magnetic field and the temperature change of the motor. The main functions include overload, locked rotor, phase loss, overheat protection and wear monitoring, The protection function is perfect, the disadvantage is that the magnetic field detection coil and temperature sensor need to be installed inside the motor.

If you have a need for PCB copying of a motor protector, you only need to provide one or two sets of prototypes or prototypes, and the PCB factory can help you imitate countless PCB circuit boards that are exactly the same as the prototypes or prototypes. And provide all technical information for your mass production.

PCB factory can provide a variety of motor protection cloning work, including intelligent protection unit, motor intelligent protector, three-phase motor protector, motor overcurrent protector, motor integrated protector, motor thermal protector, motor protector, microcomputer protection, Low-voltage protector and so on.