Introduction of chemical gold process

Chemical gold is also chemical gold. A layer of plating is formed through a chemical oxidation-reduction reaction method, which is generally thicker. It is one of the chemical nickel-gold layer deposition methods that can achieve a thicker gold layer.

Introduction of chemical gold process

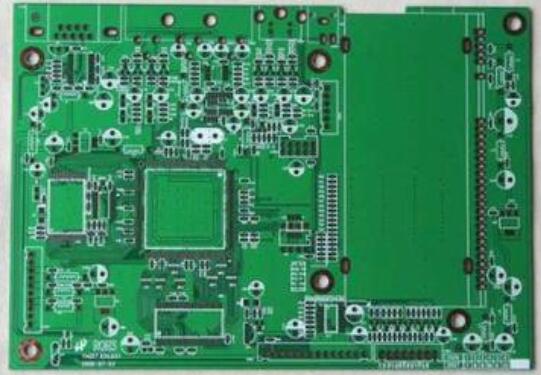

There is a very common process used in the surface treatment of PCB boards the gold immersion process. The gold immersion is the method of chemical deposition, which produces a metal plating layer on the surface of the PCB board through chemical redox reaction, which can effectively block copper and air. Oxidation is also called chemical gold.

Benefits of gold chemical process:

1. Immersion gold plates are bright in color, good in color and attractive in appearance.

2. The crystal structure formed by immersion gold is easier to weld than other surface treatments, and it has better performance and quality assurance.

3. Because the immersion gold board only has nickel and gold on the pad, it will not affect the signal, because the signal transmission in the skin effect is on the copper layer.

4. The metal properties of gold are relatively stable, the crystal structure is denser, and oxidation reactions are not prone to occur.

5. Because the immersion gold board only has nickel and gold on the pads, the solder mask on the circuit and the copper layer are more firmly bonded, and it is not easy to cause micro short circuits.

6. The project will not affect the distance during compensation.

7. The stress of the immersion gold plate is easier to control.

PCB board tg introduction

Tg is the temperature resistance value. The higher the Tg point, the higher the temperature requirement of the plate during pressing, and the pressed plate will be harder and brittle, which will affect the quality of the mechanical drilling (if any) in the subsequent process and the electrical properties during use to a certain extent. characteristic.

PCB board tg introduction

The general Tg of the plate is more than 130 degrees, the high Tg is generally more than 170 degrees, and the medium Tg is about more than 150 degrees. Usually PCB printed boards with Tg≥170 degree Celsius are called high Tg printed boards.

The advantages of high tg PCB board

1. When the temperature of a high Tg printed board rises to a certain area, the substrate will change from "glass state" to "rubber state". The temperature at this time is called the glass transition temperature (Tg) of the board. In other words, Tg is the highest temperature (°C) at which the substrate maintains rigidity.

2. That is to say, ordinary PCB substrate materials not only produce softening, deformation, melting and other phenomena at high temperatures, but also show a sharp decline in mechanical and electrical properties.

3. The Tg of the substrate is increased, and the heat resistance, moisture resistance, chemical resistance, stability and other characteristics of the printed board will be improved and improved. The higher the TG value, the better the temperature resistance of the board, especially in the lead-free process, where high Tg applications are more common.