In order to ensure the circuit performance, EMC should be considered in the PCB design of RF circuit, so the wiring principle of components is discussed to achieve the purpose of EMC.

With the development of communication technology, handheld wireless RF circuit technology is more and more widely used, such as wireless pager, mobile phone, wireless PDA, etc. the performance index of RF circuit directly affects the quality of the whole product. One of the biggest features of these handheld products is miniaturization, which means that the density of components is very high, which makes the mutual interference of components (including SMD, SMC, bare chip, etc.) very prominent. If the electromagnetic interference signal is not handled properly, the whole circuit system may not work normally. Therefore, how to prevent and suppress electromagnetic interference and improve electromagnetic compatibility has become a very important topic in the design of RF circuit PCB. The performance indexes of the same circuit and different PCB design structures will vary greatly. In this discussion, when using Protel99 se software to design the RF circuit PCB of handheld products, if the performance index of the circuit is realized to the greatest extent, so as to meet the requirements of electromagnetic compatibility.

1 Selection of RF circuit PCB board

The substrates of RF circuit PCB include organic and inorganic. The most important property in the substrate is the dielectric constant ε r. Dissipation factor (or dielectric loss) Tan δ, Coefficient of thermal expansion CET and moisture absorption. among ε R affects the circuit impedance and signal transmission rate. For high-frequency circuits, dielectric constant tolerance is the most important factor to be considered, and the substrate with small dielectric constant tolerance should be selected.

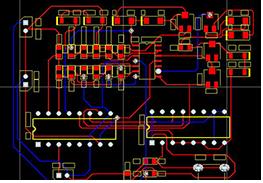

2 design flow of RF circuit PCB

Because the use of Protel99 se software is different from Protel 98 and other software, firstly, the process of PCB design using Protel99 se software is briefly discussed.

1. Since Protel99 se adopts project database mode management, which is implicit under Windows 99, a database file should be established first to manage the designed circuit schematic diagram and PCB layout.

2. Schematic design. In order to realize network connection, the components used must exist in the component library during principle design. Otherwise, the required components shall be made in schlib and stored in the file.

Then, we only need to call the required components from the components library and connect them according to the designed circuit diagram.

3. After the schematic design is completed, a network table can be formed for PCB design.

4. PCB design. a. Determination of PCB shape and size. The shape and size of the PCB are determined according to the position of the PCB in the product, the size and shape of the space, and the cooperation with other components. On the mechanical layer layer, use the place track command to draw the shape of the PCB. b. According to the requirements of SMT, make positioning holes, sight glasses, reference points, etc. on PCB. c. Manufacturing of components. If you need to use some special components that do not exist in the component library, you need to make components before layout. The process of making components in Protel99 se is relatively simple. Select the "make library" command in the "design" menu to enter the component making window, and then select the "new component" command in the "tool" menu to design components. At this time, according to the shape and size of the actual components, draw the corresponding pads at a certain position on the top layer layer with the command of place pad and edit them into the required pads (including pad shape, size, inner diameter size and angle, in addition, the corresponding pin names of the pads shall be marked), and then draw the maximum shape of the components in the top overlay layer with the command of place track, Take a component name and store it in the component library. d. After the components are manufactured, the layout and wiring are carried out. These two parts are discussed in detail below. e. Inspection must be carried out after the above process is completed. On the one hand, it includes the inspection of circuit principle. On the other hand, it must also check the matching and assembly problems between them. The circuit principle can be checked manually or automatically by network (the network formed by schematic diagram can be compared with the network formed by PCB). f. After checking, archive and output the documents. In Protel99 se, you must use the "export" command in the "file" option to store files in the specified path and file (the "import" command calls a file into Protel99 SE). Note: after the "save copy as..." command in the "file" option in Protel99 se is executed, the selected file name is not visible in Windows 98, so the file cannot be seen in Explorer. This is not exactly the same as the "save as..." function in Protel 98.

3 layout of RF circuit PCB components

Because SMT generally adopts infrared furnace heat flow welding to realize the welding of components, the layout of components affects the quality of solder joints and then the yield of products. For the PCB design of RF circuit, electromagnetic compatibility requires that each circuit module should not produce electromagnetic radiation as far as possible and have certain anti-electromagnetic interference ability. Therefore, the layout of components also directly affects the interference and anti-interference ability of the circuit itself, which is also directly related to the performance of the designed circuit. Therefore, in the PCB design of RF circuit, in addition to the layout of ordinary PCB design, it is also necessary to consider how to reduce the mutual interference between various parts of RF circuit, how to reduce the interference of circuit itself to other circuits and the anti-interference ability of circuit itself. According to experience, the effect of RF circuit depends not only on the performance index of RF circuit board itself, but also on the interaction with CPU processing board. Therefore, reasonable layout is particularly important in PCB design.

General principle of PCB layout of RF circuit: components shall be arranged in the same direction as far as possible, and poor welding shall be reduced or even avoided by selecting the direction of PCB entering the tin melting system; According to experience, the distance between components shall be at least 0.5mm to meet the tin melting requirements of components. If the space of PCB board allows, the distance between components shall be as wide as possible. For double-sided boards, SMD and SMC components shall be designed on one side and discrete components on the other side.

Attention shall be paid to the following in the PCB layout of RF circuit:

Firstly, determine the position of interface components with other PCB boards or systems on the PCB board, and pay attention to the coordination between interface components (such as the direction of components).

Because the volume of handheld products is very small and the arrangement of components is very compact, priority must be given to the components with large volume, determine the corresponding position and consider the cooperation between them.

Carefully analyze the circuit structure, block the circuit (such as high-frequency amplification circuit, mixing circuit and demodulation circuit), separate the strong current signal and weak current signal as far as possible, and separate the digital signal circuit and analog signal circuit. The circuits that complete the same function should be arranged within a certain range as far as possible, so as to reduce the signal loop area; The filter network of each part of the circuit must be connected nearby, which can not only reduce the radiation, but also reduce the probability of interference, according to the anti-interference ability of the circuit.

The unit circuits are grouped according to their sensitivity to electromagnetic compatibility in use. For the components in the easily disturbed part of the circuit, try to avoid the interference source (such as the interference from the CPU on the data processing board).

4 wiring of RF circuit PCB

After the layout of components is basically completed, the wiring can be started. The basic principle of wiring is: when the assembly density permits, the low-density wiring design shall be selected as far as possible, and the signal routing shall be consistent as far as possible, which is conducive to impedance matching.

For RF circuits, the unreasonable design of signal line direction, width and line spacing may cause cross interference between signal transmission lines; In addition, the system power supply itself also has noise interference, so when designing the RF circuit PCB, we must comprehensively consider and reasonably route.

During wiring, all wiring shall be away from the frame of PCB board (about 2mm), so as to avoid wire breakage or hidden danger of wire breakage during PCB board manufacturing. The power line shall be as wide as possible to reduce the loop resistance. At the same time, the direction of power line and ground wire shall be consistent with the direction of data transmission, so as to improve the anti-interference ability; The signal line shall be as short as possible and the number of vias shall be minimized; The shorter the connection between components, the better, so as to reduce the distributed parameters and mutual electromagnetic interference; Incompatible signal lines shall be kept away from each other, and parallel routing shall be avoided as far as possible, while signal lines on both sides of the positive direction shall be perpendicular to each other; When wiring, the address side requiring a corner should be 135 ° to avoid turning right angles.

During wiring, the line directly connected to the pad should not be too wide, and the wiring should be away from unconnected components as far as possible to avoid short circuit; Vias shall not be painted on components, and shall be kept away from unconnected components as far as possible to avoid false welding, continuous welding, short circuit and other phenomena in production.

In the PCB design of RF circuit, the correct wiring of power line and ground line is particularly important. Reasonable design is the most important means to overcome electromagnetic interference. A considerable number of interference sources on PCB are generated through power supply and ground wire, among which the ground wire causes the most noise interference.

The main reason why the ground wire is easy to form electromagnetic interference is the impedance of the ground wire. When a current flows through the ground wire, a voltage will be generated on the ground wire, resulting in the loop current of the ground wire and the loop interference of the ground wire. When multiple circuits share a section of ground wire, a common impedance coupling will be formed, resulting in the so-called ground wire noise. Therefore, when wiring the ground wire of RF circuit PCB, you should:

Firstly, the circuit is divided into blocks. The RF circuit can basically be divided into high-frequency amplification, mixing, demodulation, local oscillator and other parts. It is necessary to provide a common potential reference point for each circuit module, that is, the ground wire of each module circuit, so that the signal can be transmitted between different circuit modules. Then, it is summarized where the RF circuit PCB is connected to the ground wire, that is, it is summarized in the general ground wire. Since there is only one reference point, there is no common impedance coupling, so there is no problem of mutual interference.

The digital area shall be isolated from the analog area as far as possible, and the digital ground shall be separated from the analog ground, and finally connected to the power ground.

The ground wire inside each part of the circuit shall also pay attention to the principle of single point grounding, minimize the signal loop area, and connect with the address of the corresponding filter circuit nearby.

If space permits, it is better to isolate each module with ground wire to prevent mutual signal coupling effect.

5 conclusion of RF circuit PCB

The key of RF circuit PCB design is how to reduce the radiation ability and how to improve the anti-interference ability. Reasonable layout and wiring is the guarantee of RF circuit PCB design. The method described in this paper is helpful to improve the reliability of RF circuit PCB design, solve the problem of electromagnetic interference, and then achieve the purpose of electromagnetic compatibility.