What is gold plating?

By gold plating on the whole plate, we generally refer to "electroplated gold", "electroplated nickel plated gold plate", "electrolytic gold", "electroplated gold" and "electroplated nickel gold plate". There is a distinction between soft gold and hard gold (generally hard gold is used for gold fingers).

The principle is that nickel and gold (commonly known as gold salt) are dissolved in the chemical solution, the circuit board is immersed in the electroplating tank and connected with the current to form nickel gold coating on the copper foil surface of the circuit board.

Electroplated nickel gold has been widely used in electronic products because of its high hardness, wear resistance and difficult oxidation.

What is the immersion gold?

Immersion gold is the formation of a layer of coating by chemical oxidation-reduction reaction, which is generally thicker. It is one of the chemical nickel gold deposition methods, which can achieve a thicker gold layer.

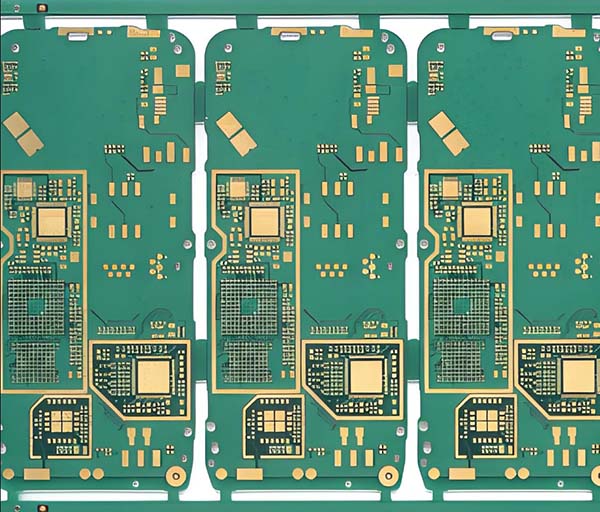

Gold immersion and gold plating are two common methods of PCB (Printed Circuit Board) surface treatment, they are significant differences in process, structure and performance:

1.Process difference

Immersion gold is deposited on the surface of the PCB through a chemical reaction of gold particles, while gold plating is the use of electroplating process to form a thin gold layer on the surface of another metal. As a result, immersion gold can cover more complex shapes more evenly, while gold plating is typically used to create thin layers of high conductivity.

2.Structure and thickness

The thickness of the gold layer formed by immersion gold is usually much greater than that of gold plating, and the gold particles on the surface of immersion gold are thicker and more golden in color. In contrast, gold plating has a thinner gold layer and is relatively white in color. This difference in thickness makes immersion gold generally superior to gold plating in terms of solderability.

3.Solderability

Immersion gold has relatively better soldering performance and is less likely to cause poor soldering, which makes it more commonly used in certain demanding electronic products. Although gold plating also has good electrical conductivity, but in some cases may be due to the thinner layer of gold resulting in inadequate solder strength.

4.Magnetic properties and discrimination

Due to the presence of nickel in the gold-plating process, gold-plated PCBs are usually magnetic. This makes it possible to identify the test by using a magnet, if there is an attraction is gold-plated, no attraction is immersion gold. This physical property not only helps to distinguish between the two treatments, but also provides a convenient way to control product quality.

5.Application Scenarios

Due to the excellent soldering performance and stability of immersion gold, it is usually used in high-frequency, high-reliability requirements of electronic equipment. The application of gold plating, on the other hand, is mostly focused on products that have a demand for cost but require a certain degree of electrical conductivity, such as ordinary consumer electronic equipment.