Basically, the purpose of setting test points is to test whether the components on the PCB circuit boardmeet the specifications and solderability. For example, if you want to check whether there is any problem with the resistance on a PCB circuit board, the easiest way is to use universal electricity. It can be known by measuring the two ends of the meter.

However, in a mass production factory, there is no way for you to use an electric meter to slowly measure whether each resistance, capacitance, inductance, and even the circuit of each IC on each board is correct, so there is the so-called ICT( The emergence of In-Circuit-Test) automated testing machines, which use multiple probes (generally called "Bed-Of-Nails" fixtures) to simultaneously contact all the parts on the board that need to be measured., And then measure the characteristics of these electronic parts in a sequence-based way through program control, and side by side as a supplement. Usually, it only takes about 1 to 2 minutes to test all parts of a general board, depending on the parts on the PCB circuit board. It depends on the quantity, the more parts the longer the time.

But if these probes directly touch the electronic parts on the board or its solder feet, it is likely to crush some electronic parts, but it is counterproductive. So smart engineers invented test points and led out extra at both ends of the parts. A pair of small round dots without a solder mask (mask) allows the test probe to touch these small dots without directly touching the electronic parts being measured.

In the early days when there were traditional plug-ins (DIP) on PCB circuit boards, the solder feet of parts were indeed used as test points. Because the solder feet of traditional parts were strong enough, they were not afraid of needle sticks, but there were often probes. The misjudgment of poor pin contact occurs, because after general electronic parts undergo wave soldering or SMT tin, a residual film of solder paste flux is usually formed on the surface of the solder. The impedance is very high, which often causes poor contact of the probe. Therefore, test operators on the production line were often seen at that time, often holding the air spray gun to blow desperately, or wipe the places that needed to be tested with alcohol.

In fact, the test points after wave soldering will also have the problem of poor probe contact. Later, after the popularity of SMT, the misjudgment of the test was greatly improved, and the application of test points was also given a great deal of responsibility, because the parts of SMT are usually very fragile and cannot withstand the direct contact pressure of the test probe. Use test points. This eliminates the need for the probe to directly contact the parts and their solder feet, which not only protects the parts from damage, but also indirectly greatly improves the reliability of the test, because there are fewer misjudgments.

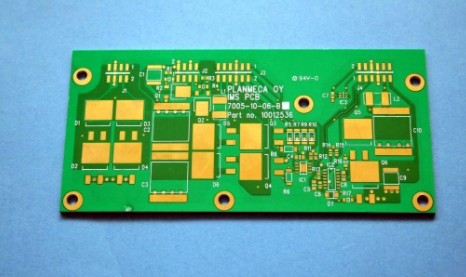

However, with the evolution of technology, the size of the PCB circuit board is getting smaller and smaller. It is already a bit difficult to squeeze so many electronic parts on the small PCB circuit board, so the test point takes up the space of the PCB circuit board., Often tug-of-war between the design side and the manufacturing side, but this topic will be discussed later when there is a chance. The appearance of the test point is usually round, because the probe is also round, which is easier to produce, and it is easier to bring the adjacent probes closer, so that the needle density of the needle bed can be increased.

1. The use of a needle bed for circuit testing has some inherent limitations on the mechanism, for example: the minimum diameter of the probe has a certain limit, and the needle with too small diameter is easy to break and damage.

2. The distance between the needles is also limited, because each needle must come out of a hole, and the back end of each needle must be welded with a flat cable. If the adjacent holes are too small, except for the needle and the needle. There will be a contact short-circuit problem, and the interference of the flat cable is also a big problem.

3. Needles cannot be implanted next to some tall parts. If the probe is too close to the high part, there is a risk of collision with the high part and cause damage. In addition, because of the high part, it is usually necessary to make holes in the needle bed of the test fixture to avoid it, which indirectly makes it impossible to implant the needle. The test points of all the components that are increasingly difficult to accommodate on the PCB circuit board.

4. As the board is getting smaller and smaller, the number of test points has been repeatedly discussed. Now there are some methods to reduce test points, such as Net test, Test Jet, Boundary Scan, JTAG, etc.; there are also other tests. The method intends to replace the original bed of needle tests, such as AOI and X-Ray, but it seems that each test cannot replace ICT 100%.

Regarding the ability of ICT needle implantation, you should ask the matching fixture manufacturer, that is, the minimum diameter of the test point and the minimum distance between adjacent test points. Usually there will be a desired minimum value and a minimum value that the ability can achieve, but there are Large-scale PCB manufacturers will require that the distance between the minimum test point and the minimum test point cannot exceed a few points during PCB manufacturing, otherwise the fixture will be easily damaged.